Organic exhaust gas degradation method and device

An organic waste gas and photocatalyst technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of death, microorganisms are susceptible to poisoning, and cannot completely degrade organic matter, and achieve the effect of improving the degradation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

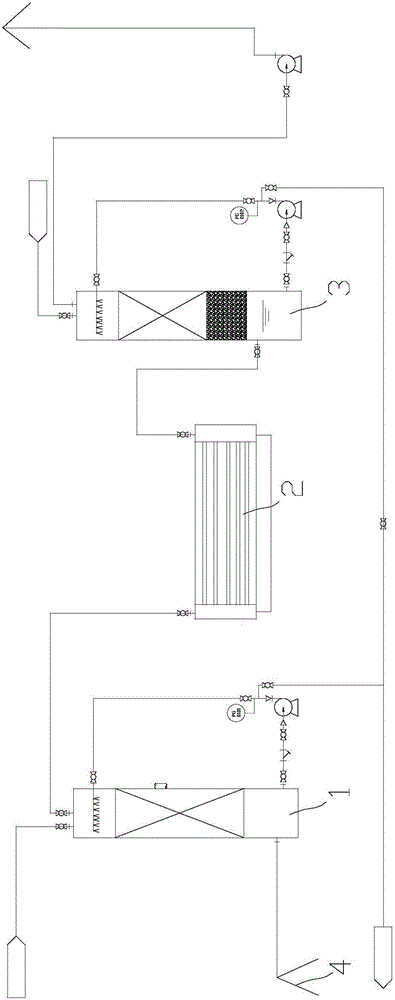

Image

Examples

Embodiment 1

[0038] A mixed organic waste gas containing toluene, xylene, ethyl acetate, ethers, and ketones, the concentration of non-methane total hydrocarbons at the inlet is 2000mg / m 3, the wind volume is about 24000m 3 / h.

[0039] (1) Photocatalysis: Exhaust gas enters the photocatalytic oxidation reactor 2 through the induced draft fan for photocatalytic oxidation treatment. The photocatalyst carrier is made of alumina, and the active component is made of titanium dioxide. The coating density of the catalyst on the screen is 0.5kg / m 2 .

[0040] (2) Catalytic oxidation washing: the gas obtained after the step (1) treatment enters the catalytic oxidation washing tower 3, and the catalyst in the catalytic oxidation washing tower 3 takes activated carbon as a carrier, and takes iron oxide as an active component, and the loading of iron oxide in the catalyst The amount is 1%, and the mass fraction of 1% H is used for washing 2 o 2 The aqueous solution is used as the oxidant, and th...

Embodiment 2

[0044] A mixed organic waste gas containing xylene, butyl acetate, ethyl acetate, and methyl isobutyl ketone, the concentration of non-methane total hydrocarbons at the inlet is 4000mg / m 3 , the wind volume is about 35000m 3 / h.

[0045] (1) Photocatalysis: The organic waste gas enters the photocatalytic oxidation reactor 2 through the induced draft fan for photocatalytic oxidation treatment. The photocatalyst carrier adopts alumina, the active component adopts cobalt oxide, and the loading capacity of cobalt oxide in the photocatalyst is 1 %.

[0046] (2) Catalytic washing: the gas obtained after the step (1) is processed enters the catalytic oxidation scrubber 3, and in the catalytic oxidation scrubber 3, the catalyzer takes activated carbon as a carrier, and takes copper oxide as an active component, and the loading capacity of copper oxide in the catalyzer is 1%, the sodium hypochlorite aqueous solution with a mass fraction of 0.5% is used as the washing oxidant, and the...

Embodiment 3

[0050] A certain organic waste gas containing acrylonitrile and chloropropene, the concentration of non-methane total hydrocarbons at the inlet is 1000mg / m 3 , the wind volume is about 10000m 3 / h.

[0051] (1) Photocatalysis: Exhaust gas enters the photocatalytic oxidation reactor 2 through the induced draft fan for photocatalytic oxidation treatment. The photocatalyst carrier adopts molecular sieve, and the active component adopts titanium dioxide. The coating density on the screen is 1kg / m 2 .

[0052] (2) Catalytic oxidation washing: the gas obtained after the step (1) treatment enters the catalytic oxidation washing tower 3, and the catalyst in the catalytic oxidation washing tower 3 takes activated carbon as a carrier, and takes nickel oxide as an active component, and the loading of nickel oxide in the catalyst The amount is 0.5%, and the mass fraction of washing is 0.5% H 2 o 2 The aqueous solution is used as the oxidant, and the spray liquid-gas ratio of the oxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com