Measuring method for nano titanium dioxide migration quantity in food plastic package product

A technology of nano-titanium dioxide and plastic packaging, which is applied in the direction of measuring devices, analyzing materials, and material analysis through electromagnetic means, which can solve the problems of the measurement of nano-titanium dioxide migration and low migration, and achieve the effect of simple measurement methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

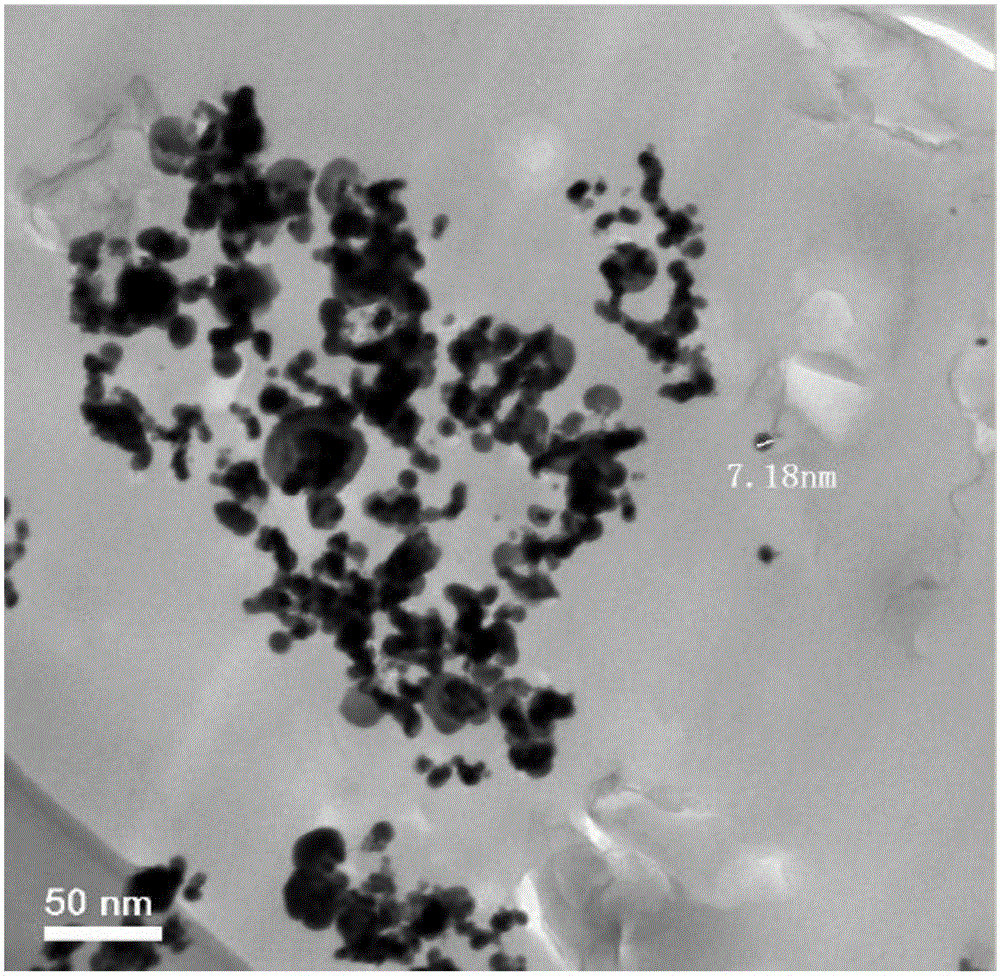

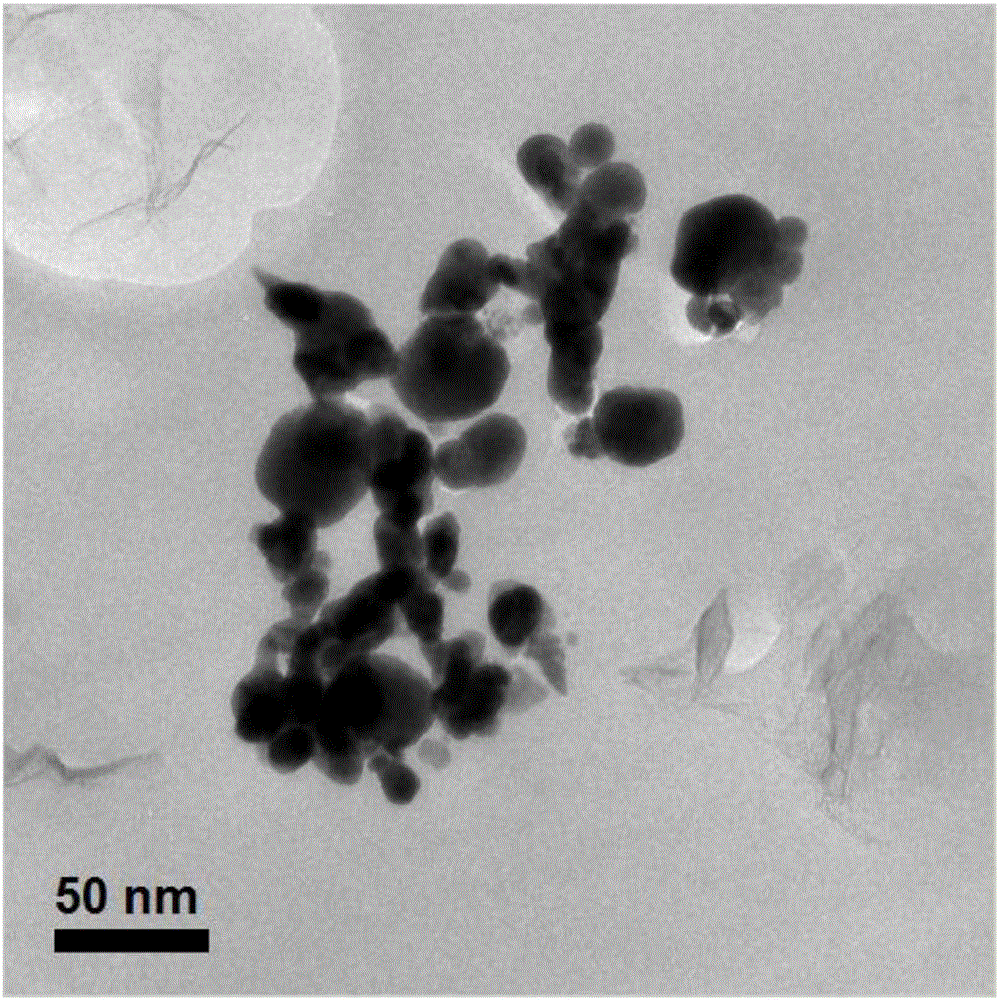

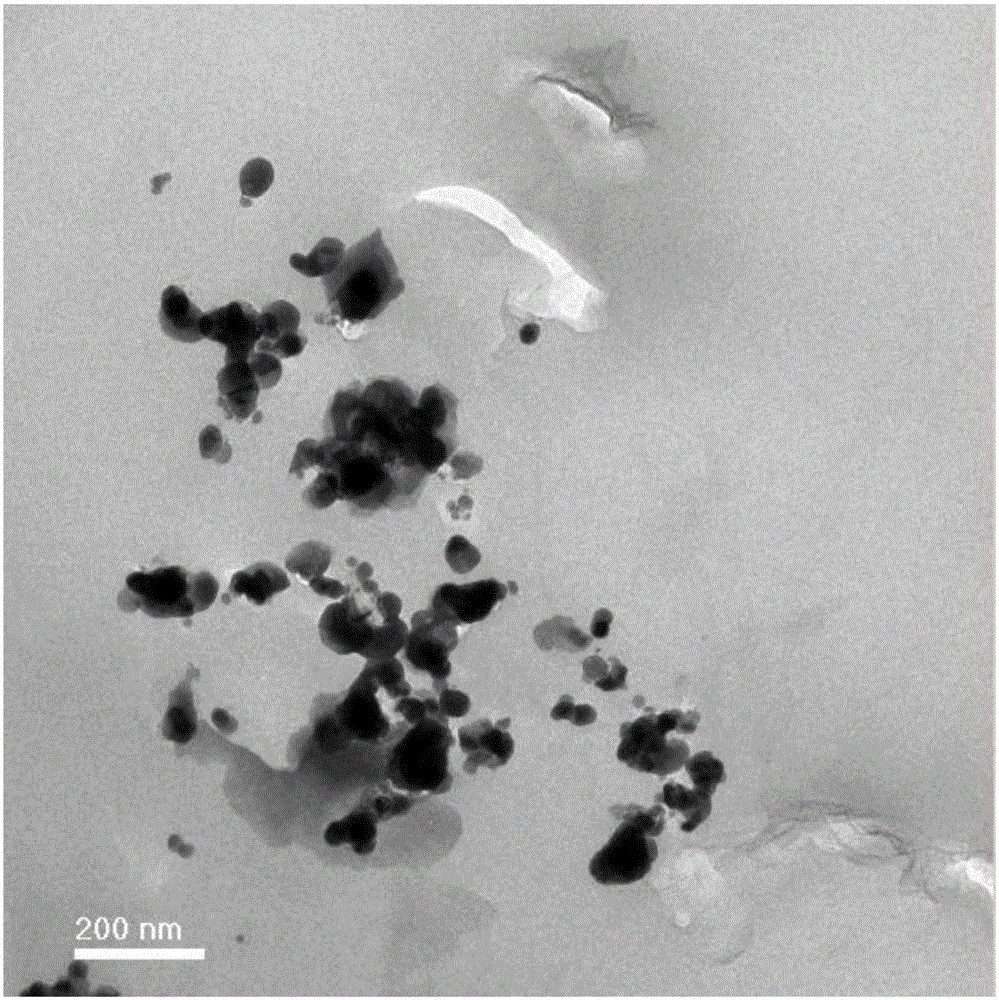

[0020] Embodiment 1: the assay method of nano-titanium dioxide migration in food plastic packaging products

[0021] 1.1 Samples, reagents and instruments used in the test

[0022] The selected food plastic packaging samples are nano-titanium dioxide PP sheets (purchased from Ningbo Jialian Plastic Products Co., Ltd.). In this embodiment, three different nano-titanium dioxide PP sheets are selected for testing, namely sample a, sample b and sample c; Acidic food simulant liquid selects 4% (volume fraction) acetic acid for use, and wherein glacial acetic acid is superior grade pure (purchased in Sinopharm Group); concentrated sulfuric acid is superior grade pure (purchased in Sinopharm Group); ammonium sulfate is analytically pure (purchased in Sinopharm Group); Sinopharm Group).

[0023] The main instruments used in the experiment are as follows: SEM Quanta TM 250 (FEI, USA); inductively coupled plasma mass spectrometer Agilengt 7500A (Agilent, USA); water bath HH-60 (Changz...

Embodiment 2

[0041] Embodiment 2: the mensuration of detection limit and recovery rate

[0042]2.1 Using the above-mentioned measurement conditions, under the same experimental conditions, the titanium concentration of the blank solution was continuously measured 11 times, and the detection limit of titanium was 3 times of the standard deviation, and the detection limit of titanium dioxide was calculated according to formula Ⅰ. The results are shown in Table 2. The above blank solution was prepared by the following steps: 100 mL of 4% (volume fraction) acetic acid solution, evaporated to dryness, added 1.6 g of ammonium sulfate and 4 mL of concentrated sulfuric acid, heated and dissolved on a heating plate until clarified. After cooling, transfer the volume to a 100mL volumetric flask with water, and the resulting solution is the reagent blank solution.

[0043] Table 2 Detection Limits

[0044]

[0045] As can be seen from Table 2, adopt the assay method of invention, its detection l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com