T-shaped steel member

A technology of T-shaped steel and steel components, which is applied to building components, elongated structural components for load-bearing, structural elements, etc. The effect of bearing capacity, reducing steel consumption and improving component performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The T-shaped steel member of the present invention will be described in detail below with reference to the drawings and embodiments.

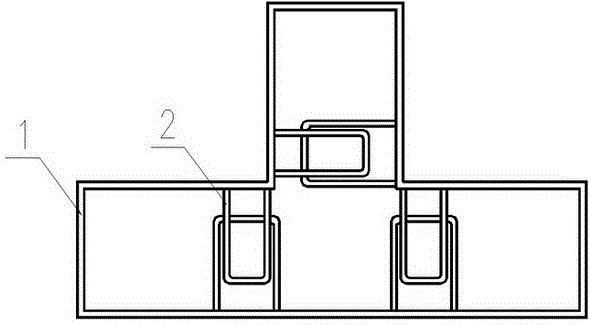

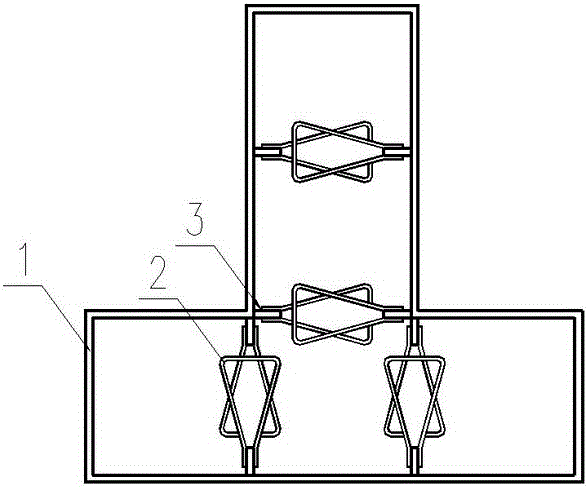

[0036] A schematic cross-sectional view of an embodiment of the T-shaped steel member proposed by the present invention, as figure 1 , the T-shaped steel member includes a T-shaped steel part 1 and a connecting part 2, and the opposite connecting parts 2 are overlapped together; the connecting parts are arranged at a certain interval along the longitudinal direction of the steel part, figure 1 Among them is a section of the steel part and the arrangement of the connecting parts; the connecting parts are made of steel rods, or the connecting parts are made of deformed steel bars, or made of steel strips; figure 1 The connector 2 is U-shaped. figure 1 The widths of the U-shaped connectors on the opposite side are the same, and for the convenience of expression, the widths of the U-shaped connectors on the opposite sides are differentiated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com