Uniform temperature type polysilicon reducing furnace

A polysilicon and reduction furnace technology, applied in silicon compounds, sustainable manufacturing/processing, inorganic chemistry, etc., can solve the problems of high energy consumption, small output per furnace, thermal deformation of thick tube sheets, etc. Reduce welding workload and solve the effect of thermal deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

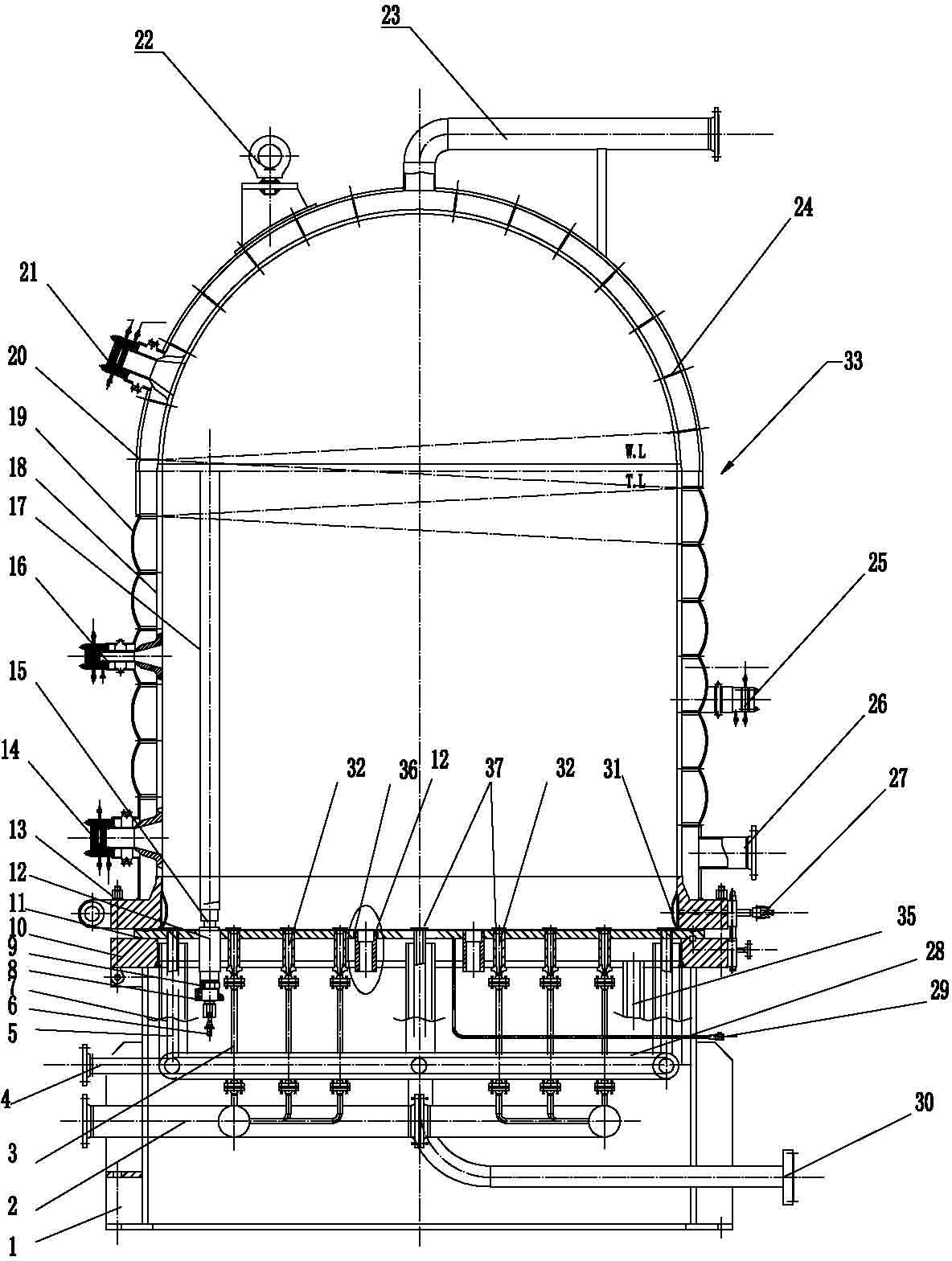

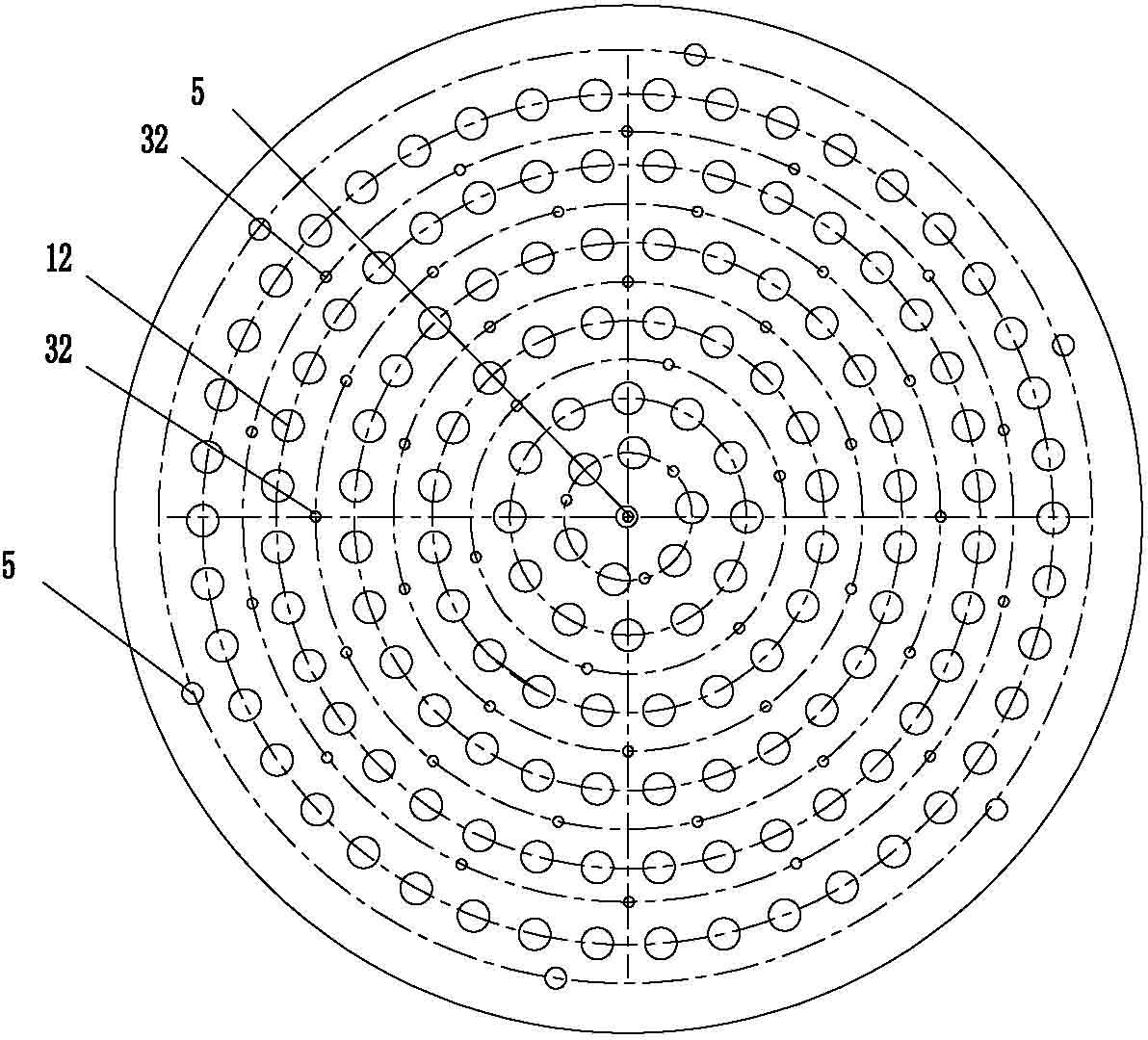

[0042] Such as figure 1 -6 shown.

[0043] A bell type large-scale polysilicon reduction furnace, which includes a support 1, a water jacket tube plate 10 and a furnace body 33, the water jacket tube plate 10 is installed on the support 1, and the furnace body 33 is installed on the water clamp through a flange The casing tube plate 10 is provided with a water jacket 31 on the flange connecting the furnace body 33 and the water jacket tube plate 10, and the water inlet 27 of the water jacket 31 is connected with the cooling water source, and the other part of the water inlet 27 of the water jacket 31 One end is correspondingly provided with the water outlet 27 of water jacket 31 and is connected with cooling water drain pipe; Described furnace body 33 is made up of furnace cylinder inner wall 18 and arc-shaped furnace outer cylinder 19 and spherica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com