Rapid quantitative filter paper and preparation method thereof

A quantitative filter paper, rapid technology, applied in the field of filter paper, can solve the problems of paper leakage, lower filtration accuracy, poor water resistance of quantitative filter paper, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

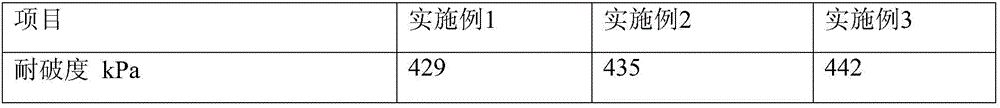

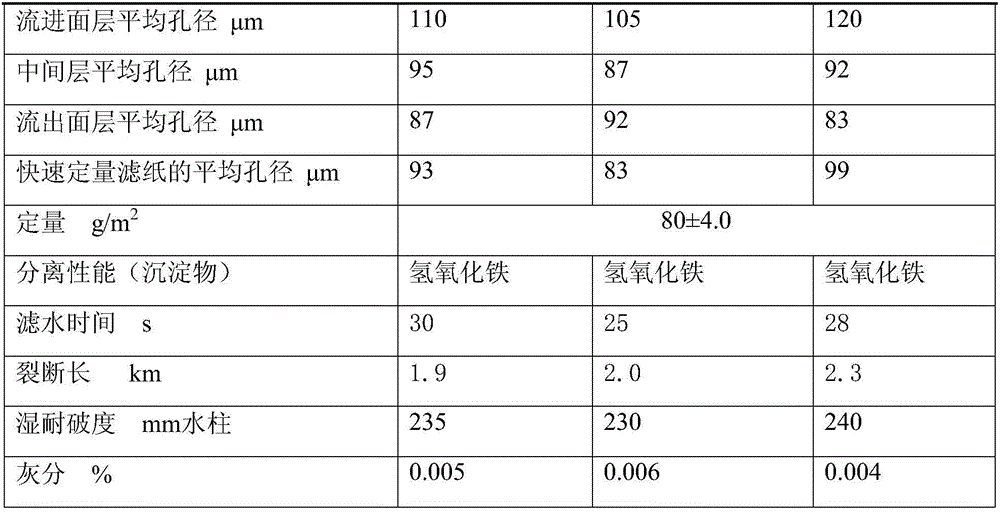

Embodiment 1

[0019] Rapid quantitative filter paper has a three-layer structure from the inflow surface to the outflow surface of the filter paper, and the middle layer of the three-layer structure includes 20 parts of softwood pulp and 40 parts of hardwood pulp in parts by weight; The flow-in surface layer includes 20 parts of softwood pulp and 30 parts of short-staple cotton pulp in parts by weight, and the outflow surface layer includes 20 parts of hardwood pulp and 30 parts of short-staple cotton in parts by weight. paddle; the softwood pulp, hardwood pulp and linter cotton pulp are respectively soaked in hydrofluoric acid and hydrochloric acid mixture, then neutralized by alkali, and finally washed with ion-exchanged pure water or distilled water to obtain the obtained. The α-cellulose content in the rapid quantitative filter paper is 98%.

[0020] The total weight is 80±4.0g / m 2 , Quantitative flow into the surface layer is 30±2g / m 2 , the middle layer is 20±1g / m 2 , the outflow s...

Embodiment 2

[0030] Rapid quantitative filter paper has a three-layer structure from the inflow surface to the outflow surface of the filter paper, and the middle layer of the three-layer structure includes 40 parts of softwood pulp and 20 parts of hardwood pulp in parts by weight; The flow-in surface layer includes 40 parts of softwood pulp and 80 parts of short-staple cotton pulp in parts by weight, and the outflow surface layer includes 40 parts of hardwood pulp and 30 parts of short-staple cotton in parts by weight. paddle; the softwood pulp, hardwood pulp and linter cotton pulp are respectively soaked in hydrofluoric acid and hydrochloric acid mixture, then neutralized by alkali, and finally washed with ion-exchanged pure water or distilled water to obtain the obtained. The α-cellulose content in the rapid quantitative filter paper is 99%.

[0031] As a preference, the total weight is 80±4.0g / m 2 , Quantitative flow into the surface layer is 30±2g / m 2 , the middle layer is 20±1g / m ...

Embodiment 3

[0041] Rapid quantitative filter paper has a three-layer structure from the inflow surface to the outflow surface of the filter paper, and the middle layer of the three-layer structure includes 30 parts of softwood pulp and 20 parts of hardwood pulp in parts by weight; The flow-in surface layer includes 30 parts of softwood pulp and 60 parts of short-staple cotton pulp in parts by weight, and the outflow surface layer includes 40 parts of hardwood pulp and 50 parts of short-staple cotton in parts by weight. paddle; the softwood pulp, hardwood pulp and linter cotton pulp are respectively soaked in hydrofluoric acid and hydrochloric acid mixture, then neutralized by alkali, and finally washed with ion-exchanged pure water or distilled water to obtain the obtained. The α-cellulose content in the rapid quantitative filter paper is 98.5%.

[0042] As a preference, the total weight is 80±4.0g / m 2, Quantitative flow into the surface layer is 30±2g / m 2 , the middle layer is 20±1g / m ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com