Handle type blade with three pressure sensing holes at front edge of each element stage

A primitive-level, leading-edge technology, applied in pump components, non-variable-capacity pumps, components of pumping devices for elastic fluids, etc. The effect of light weight, improved measurement resolution, and reduced blade weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

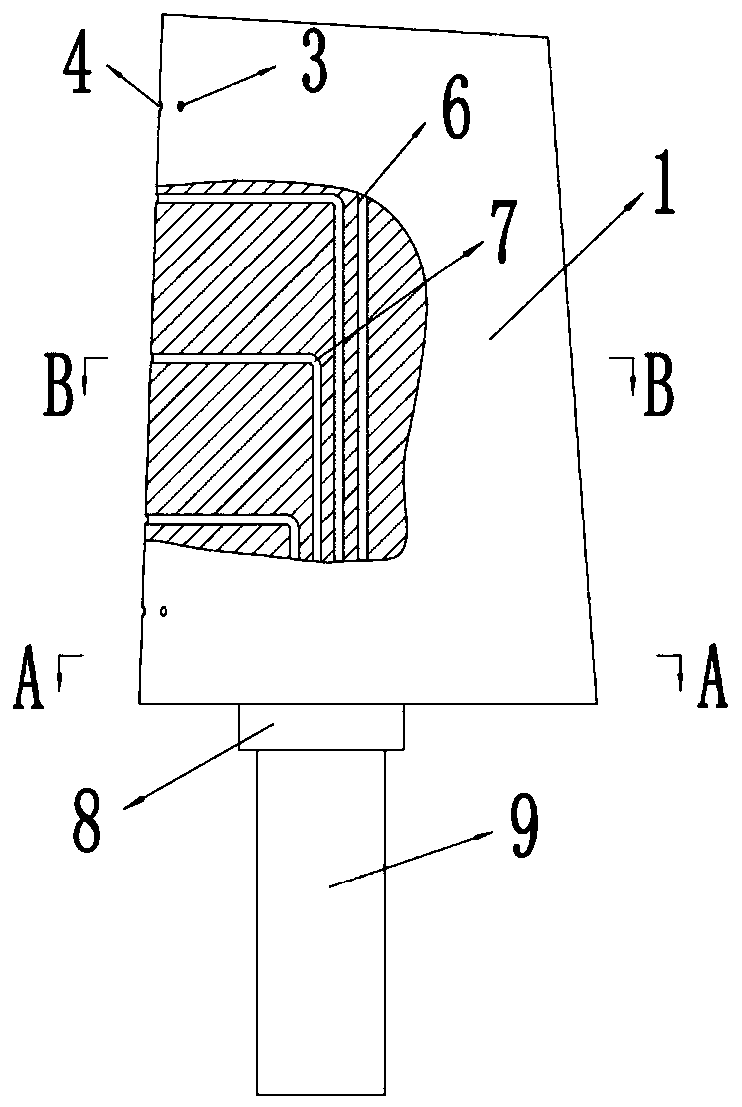

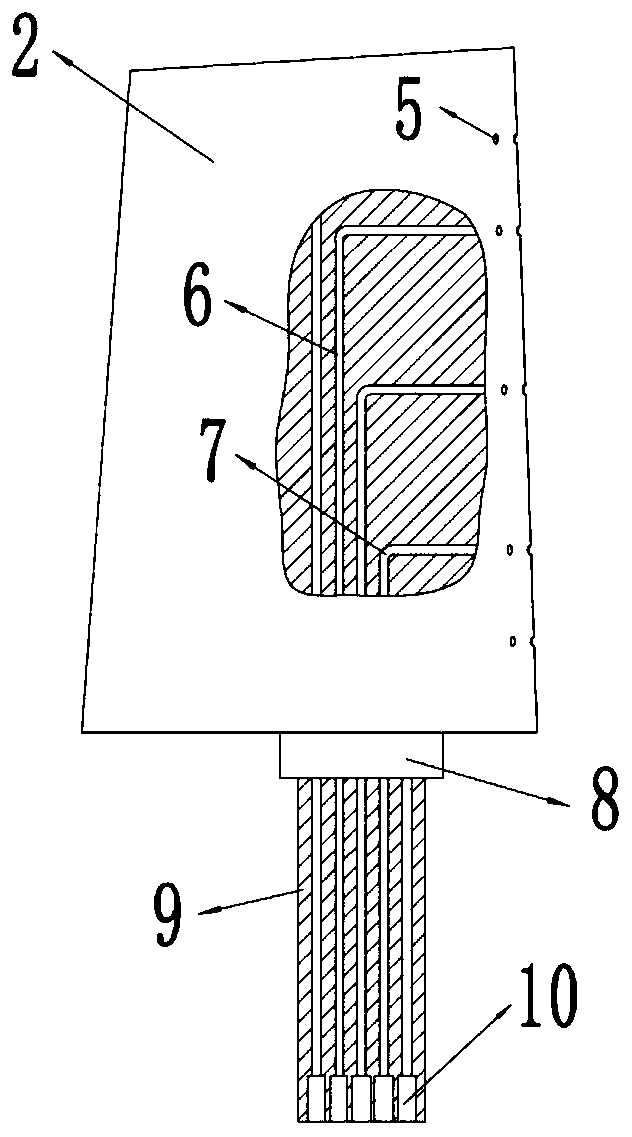

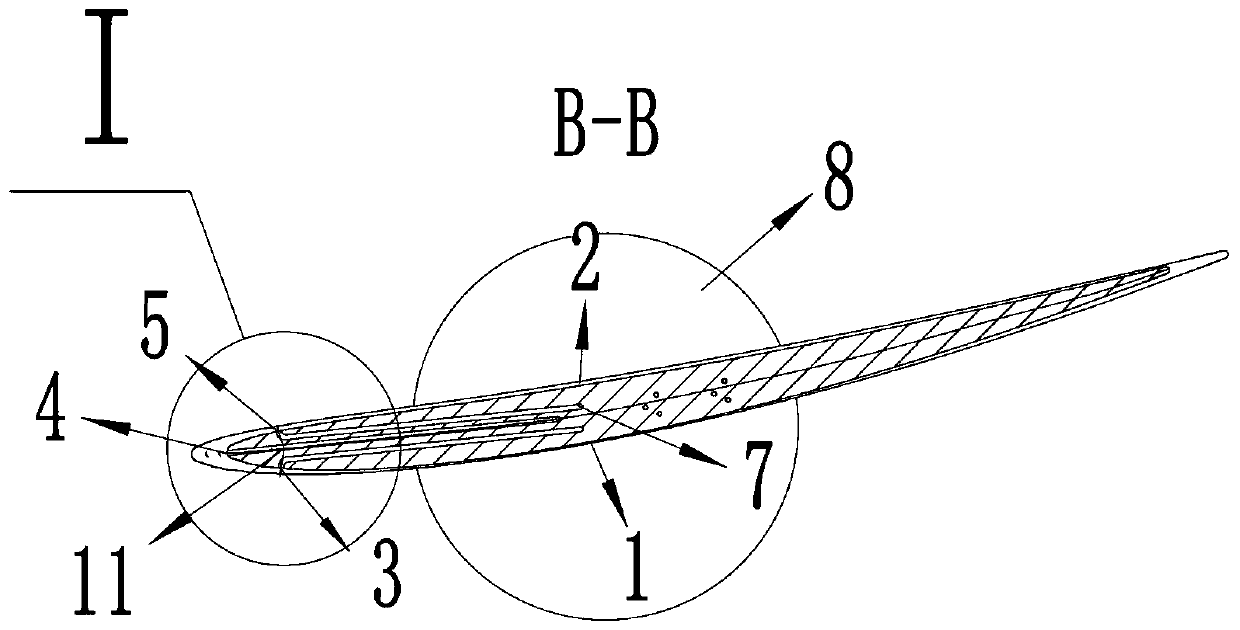

[0034] Such as figure 1 and figure 2 As shown, this embodiment introduces a handle-type blade with three pressure-sensing holes on the leading edge of the primitive level; the blade has a small twist and includes a blade suction surface (1), a blade pressure surface (2), Suction surface pressure sensing hole (3), leading edge point pressure sensing hole (4), pressure surface pressure sensing hole (5), pressure introduction channel (6), low loss elbow (7), handle boss (8), Handle (9), pressure induction tube interface (10). Among them, the blade has multiple rows of pressure sensing holes distributed along the leaf height direction, the center line of each row of pressure sensing holes is on the same primitive level, and the diameter of each hole is 0.4mm. From the direction of the leaf root, the first row of pressure sensing holes is 1mm away from the leaf root, the second row is at 25% of the leaf height, the third row is at 50% of the leaf height, the fourth row is at 75%...

Embodiment 2

[0039] Such as Figure 7 and Figure 8 As shown, this embodiment introduces a handle-type blade with three pressure-sensing holes on the leading edge of the primitive level; the blade has a certain twist, including the blade suction surface (1), the blade pressure surface (2), Suction surface pressure sensing hole (3), leading edge point pressure sensing hole (4), pressure surface pressure sensing hole (5), pressure introduction channel (6), low loss elbow (7), handle boss (8), Handle (9), pressure induction tube interface (10). Among them, the blade has multiple rows of pressure sensing holes distributed along the leaf height direction, the center line of each row of pressure sensing holes is on the same primitive level, and the diameter of each hole is 0.4mm. From the direction of the leaf root, the first row of pressure sensing holes is 1mm away from the leaf root, the second row is at 25% of the leaf height, the third row is at 50% of the leaf height, the fourth row is a...

Embodiment 3

[0045] Such as figure 1 and figure 2 As shown, this embodiment introduces a handle-type blade with three pressure-sensing holes on the leading edge of the primitive level; the blade has a small twist and includes a blade suction surface (1), a blade pressure surface (2), Suction surface pressure sensing hole (3), leading edge point pressure sensing hole (4), pressure surface pressure sensing hole (5), pressure introduction channel (6), low loss elbow (7), handle boss (8), Handle (9), pressure induction tube interface (10). Among them, the blade has multiple rows of pressure sensing holes distributed along the leaf height direction, the center line of each row of pressure sensing holes is on the same primitive level, and the diameter of each hole is 0.4mm. From the direction of the leaf root, the first row of pressure sensing holes is 1mm away from the leaf root, the second row is at 25% of the leaf height, the third row is at 50% of the leaf height, the fourth row is at 75%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com