Method for selectable single-side growth of graphene on SiC substrate

A graphene and selective technology, applied in the field of microelectronic materials, to reduce the cost of use, suppress double-sided graphene, and improve the surface morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A method for selective single-sided growth based on SiC epitaxial graphene, comprising the steps of:

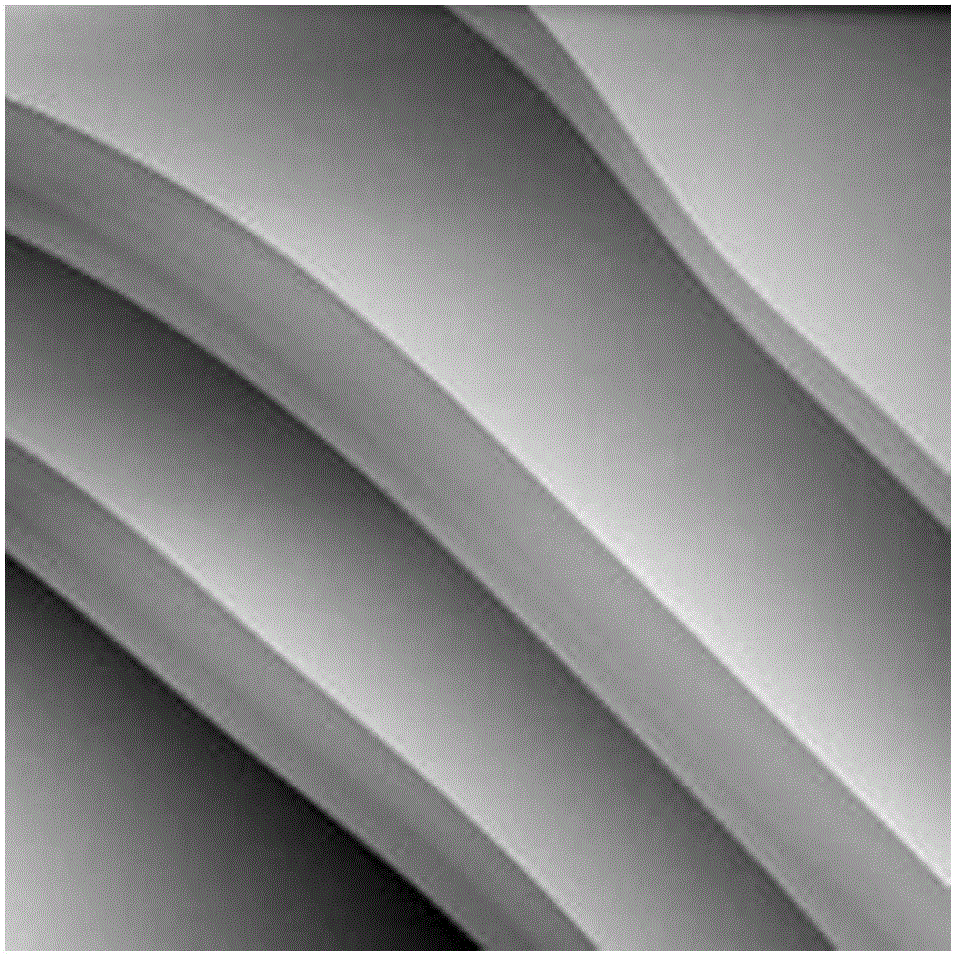

[0056] (1) Grind and polish the 2-inch diameter 4H-SiC substrate wafer on both sides, so that the surface roughness is less than 0.5nm, and the flatness is less than 6μm, and a 4H-SiC substrate with a thickness of 400μm is obtained. Standard cleaning of the surface is then carried out.

[0057] (2) Grinding and polishing the Si surface of the 2-inch diameter 4H-SiC cover sheet, so that the surface roughness is less than 3nm, and the flatness is less than 15 μm, and a 4H-SiC wafer with a thickness of 500 μm is obtained. Standard cleaning of the surface is then carried out.

[0058] (3) Place a 2-inch graphite crucible in a vertical heating growth furnace, place the 4H-SiC substrate Si prepared in the above step (1) face down on the center of the graphite crucible, and then place the Si surface prepared in the above step (2) The Si surface of the 4H-SiC wafer is superi...

Embodiment 2

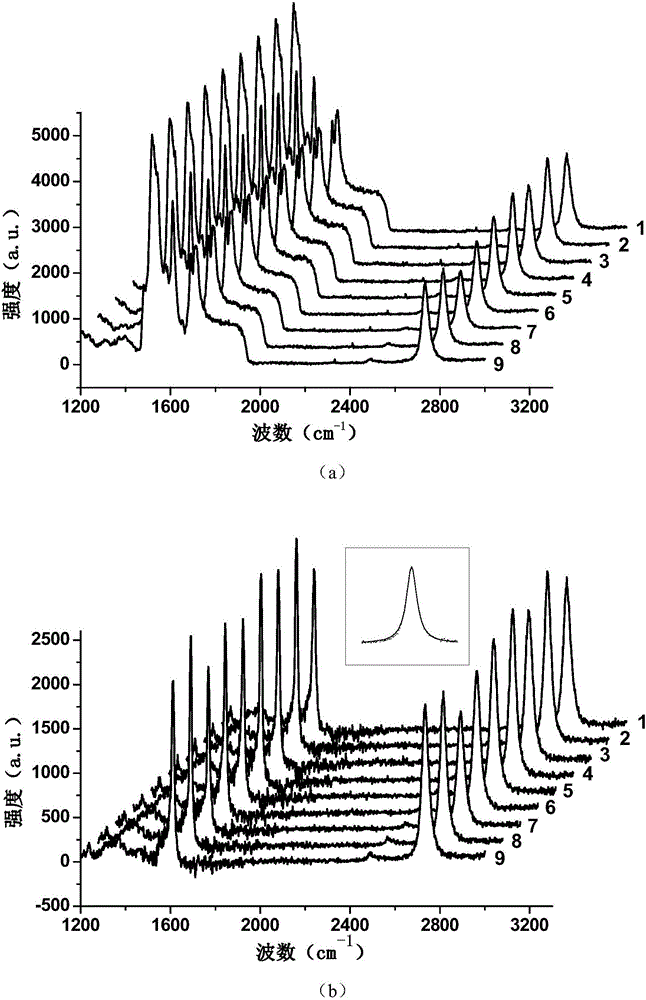

[0063] A kind of method based on the optional single-sided growth of SiC epitaxial graphene, according to the graphene growth method identical with embodiment 1, its difference is, the 2 inches 4H-SiC substrate C that has processed is faced The bottom is placed flat in the growth furnace crucible, and the growth temperature is controlled at 1550 °C. Raman spectroscopy and atomic force microscopy were used to characterize the obtained graphene material, the shape of graphene is uniform; the Hall mobility is 3500cm 2 / v·s.

Embodiment 3

[0065] A kind of method based on SiC epitaxial graphene alternative single-sided growth method, according to the graphene growth method identical with embodiment 1, its difference is, the 3 inch 4H-SiC substrate Si that has processed is faced The bottom is placed in the crucible of the growth furnace, and the polished Ta sheet is used to overlay the substrate. Test and characterize the grown graphene, the number of layers is a single layer; the Hall mobility is 1500cm 2 / v·s.

[0066] Through the description of Examples 1-3, combined with the characterization results of the graphene materials in the examples, it can be seen that the inventive method can effectively suppress the formation of graphene on the non-selective growth surface, and eliminate the test deviation produced by the double-sided graphene on the substrate ; The quality, uniformity and mobility of the grown graphene are all improved, which will be beneficial to the application of SiC substrate epitaxial graphe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com