Lubricant containing silicon dioxide and used for enamelled wire

A silicon dioxide and lubricant technology, applied in lubricating compositions, petroleum industry, etc., can solve the problems of payoff breakage, paraffin lubricant prone to precipitation, enameled wire winding, etc., to achieve low friction resistance and impact resistance. Good, good lubricity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

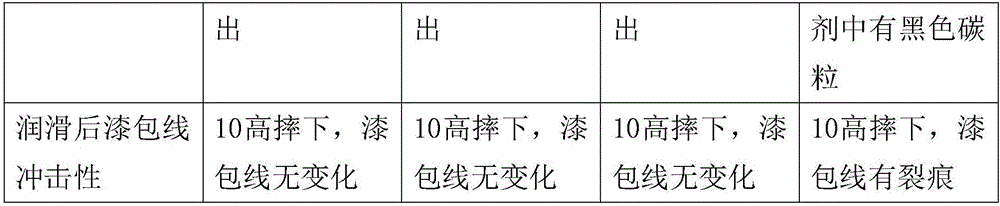

Examples

Embodiment 1

[0016] A silicon dioxide-containing lubricant for enameled wires is made of the following raw materials in parts by weight: 60 parts of yellow wax, 13 parts of 52% chlorinated paraffin, 13 parts of N-dimethyl-p-methylaniline, and 13 parts of propylene glycol 17 parts of silicon dioxide, 8 parts of camphor oil, 28 parts of No. 93 gasoline, 60 parts of industrial ethanol, and 19 parts of lubricant;

[0017] The moisturizer is made of the following raw materials in parts by weight: 9 parts of coconut oil, 9 parts of 1,3-cyclohexadiene, 9 parts of fish oil, 9 parts of peanut oil, 8 parts of ethyl cellulose, naphthalene 8 parts, 8 parts of hexachlorocyclohexane, 8 parts of 2,4-dinitrobenzoic acid, 3.8 parts of maleic anhydride, 3.8 parts of sodium citrate, 3.8 parts of methyl sorbate, 3.8 parts of urotropine 9 parts, 9 parts of fatty acid polyoxyethylene esters, 9 parts of β-naphthalenesulfonic acid, 9 parts of N-methylpyrrolidone, 12 parts of 4-benzylaminoquinoline, 12 parts of me...

Embodiment 2

[0023] A silicon dioxide-containing lubricant for enameled wires is made of the following raw materials in parts by weight: 50 parts of yellow wax, 10 parts of 52% chlorinated paraffin, 11 parts of N-dimethyl-p-methylaniline, and 11 parts of propylene glycol 14 parts of silicon dioxide, 6 parts of camphor oil, 22 parts of No. 93 gasoline, 55 parts of industrial ethanol, 14 parts of lubricant;

[0024] The moisturizer is made of the following raw materials in parts by weight: 5 parts of coconut oil, 5 parts of 1,3-cyclohexadiene, 5 parts of fish oil, 5 parts of peanut oil, 5 parts of ethyl cellulose, naphthalene 5 parts, 5 parts of hexachlorocyclohexane, 5 parts of 2,4-dinitrobenzoic acid, 3.5 parts of maleic anhydride, 3.5 parts of sodium citrate, 3.5 parts of methyl sorbate, 3.5 parts of urotropine 8 parts, 8 parts of fatty acid polyoxyethylene esters, 8 parts of β-naphthalenesulfonic acid, 8 parts of N-methylpyrrolidone, 8.5 parts of 4-benzylaminoquinoline, 8.5 parts of meth...

Embodiment 3

[0030] A silicon dioxide-containing lubricant for enameled wire, made of the following raw materials in parts by weight: 68 parts of yellow wax, 16 parts of 52% chlorinated paraffin, 15.6 parts of N-dimethyl-p-methylaniline, 15.6 parts of propylene glycol 19 parts of silicon dioxide, 10 parts of camphor oil, 35 parts of No. 93 gasoline, 65 parts of industrial ethanol, 24 parts of lubricant;

[0031] The moisturizer is made of the following raw materials in parts by weight: 12.5 parts of coconut oil, 12.5 parts of 1,3-cyclohexadiene, 12.5 parts of fish oil, 12.5 parts of peanut oil, 10 parts of ethyl cellulose, naphthalene 10 parts, 10 parts of hexachlorocyclohexane, 10 parts of 2,4-dinitrobenzoic acid, 4 parts of maleic anhydride, 4 parts of sodium citrate, 4 parts of methyl sorbate, 4 parts of urotropine 10.5 parts, 10.5 parts of fatty acid polyoxyethylene esters, 10.5 parts of β-naphthalenesulfonic acid, 10.5 parts of N-methylpyrrolidone, 14.2 parts of 4-benzylaminoquinoline...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com