Soil conditioner based on secondary use of chemical phosphorus tailings and preparation method of soil conditioner

The technology of soil conditioner and phosphorus chemical industry is applied in the field of soil conditioner based on the secondary utilization of phosphorus chemical tailings, which can solve the problems of land occupation, pollution of ecological environment, ineffective utilization of phosphate ore dressing tailings, etc., so as to prevent lodging. phenomenon, reduce leaching loss, and improve the effect of crop survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In the present embodiment, 100 kg of the soil conditioner based on the secondary utilization of phosphorus chemical industry tailings to prepare the present invention is 100 kg, and the specific steps are:

[0022] Step 1. Use any one or more of corn stalks, wheat stalks, turmeric stalks, sorghum stalks, and rice stalks as raw materials, and decarbonize them at a temperature of 500°C to 700°C for 2-3 hours to prepare biological activated carbon. ;

[0023] Step 2, mechanically pulverize biological activated carbon, phosphate chemical tailings, weathered coal and kaolin into powders respectively, and dry them in the sun; the phosphorous chemical tailings used include 35% of calcium oxide and 60% of sulfur trioxide in mass percentage , 2% silicon dioxide, 0.3% aluminum oxide, 0.1% iron oxide, and 0.03% magnesium oxide; in addition, the phosphorus chemical tailings may also contain other impurities, which generally do not affect the aforementioned ingredients in the soil c...

Embodiment 2

[0027] In the present embodiment, 300kg of the soil conditioner based on the secondary utilization of phosphorus chemical tailings of the present invention are prepared, and the specific steps are:

[0028] Step 1. Use any one or more of corn stalks, wheat stalks, turmeric stalks, sorghum stalks, and rice stalks as raw materials, and decarbonize them at a temperature of 500°C to 700°C for 2-3 hours to prepare biological activated carbon. ;

[0029] Step 2, mechanically pulverize biological activated carbon, phosphating chemical tailings, weathered coal and kaolin into powder respectively, and dry them in the sun; wherein, the content of humic acid in the weathered coal is greater than 30% of the total mass of the weathered coal; in addition, the The phosphorous chemical tailings include 45% of calcium oxide, 50% of sulfur trioxide, 6% of silicon dioxide, 0.1% of aluminum oxide, 0.3% of iron oxide and 0.01% of magnesium oxide in terms of mass percentage; in addition, phosphorus...

Embodiment 3

[0033] In the present embodiment, 500kg of the soil conditioner based on the secondary utilization of phosphorus chemical industry tailings to prepare the present invention is 500kg, and the specific steps are:

[0034] Step 1. Use any one or more of corn stalks, wheat stalks, turmeric stalks, sorghum stalks, and rice stalks as raw materials, and decarbonize them at a temperature of 500°C to 700°C for 2-3 hours to prepare biological activated carbon. ;

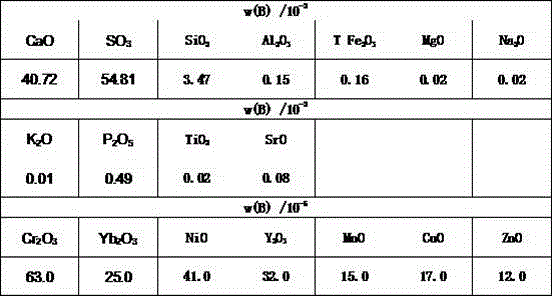

[0035] Step 2, mechanically pulverize biological activated carbon, phosphating chemical tailings, weathered coal and kaolin into powder respectively, and dry them in the sun; wherein, the content of humic acid in the weathered coal is greater than 30% of the total mass of the weathered coal; in addition, the The phosphorus chemical tailings include 40.72% of calcium oxide, 54.81% of sulfur trioxide, 3.47% of silicon dioxide, 0.15% of aluminum oxide, 0.16% of iron oxide, and 0.015% of magnesium oxide in terms of mass percentage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com