Novel high-resilience load-bearing foam material and preparation method thereof

A foam material and high-resilience technology, which is applied in the field of new high-resilience load-bearing foam materials and their preparation, can solve the problems of compression set and poor resistance to repeated indentation fatigue, and achieve good repeated indentation fatigue and openness. The effect of high porosity and delicate hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

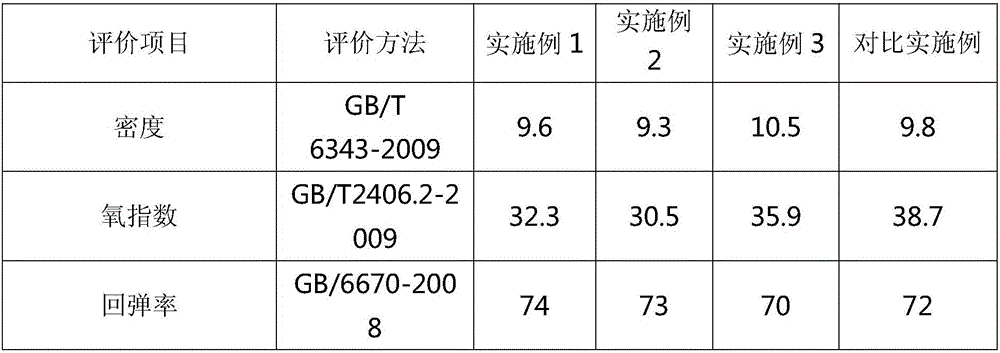

Examples

Embodiment 1

[0028] Prepare novel high-resilience load-bearing foam material according to the following steps:

[0029] (1) Preparation of expandable melamine formaldehyde resin: In a 5L stirred reactor, add 1023g of water, 1350g of paraformaldehyde, 1890g of melamine, and 106g of sodium metabisulfite, adjust the pH to 8.5-9 with triethanolamine, and react at a constant temperature of 95°C for 112min. The obtained solid content is 76.5%, and the methylol content is 22.7% of resin gross weight expandable melamine formaldehyde resin, and this resin has certain reactivity;

[0030] (2) Preparation of expandable melamine formaldehyde resin-elastomer emulsion: in a constant temperature water bath at 30°C, take 1000g of expandable melamine formaldehyde resin prepared in Example 1, add 50g of liquid nitrile rubber, fatty alcohol polyoxyethylene 14g of sodium ether sulfate, 6g of alkyl polyoxyethylene ether (AEO-9), 10g of aluminum oxide, 1g of bis-tert-butylperoxycumene, and 40g of water were uni...

Embodiment 2

[0036] Prepare novel high-resilience load-bearing foam material according to the following steps:

[0037] (1) Preparation of expandable melamine formaldehyde resin: In a 5L stirred reactor, add 1023g of water, 1350g of paraformaldehyde, 1890g of melamine, and 106g of sodium metabisulfite, adjust the pH to 8.5-9 with triethanolamine, and react at a constant temperature of 95°C for 112min. The obtained solid content is 76.5%, and the methylol content is 22.7% of resin gross weight expandable melamine formaldehyde resin, and this resin has certain reactivity;

[0038] (2) Preparation of expandable melamine formaldehyde resin-elastomer emulsion: In a constant temperature water bath at 30°C, take 1000g of expandable melamine formaldehyde resin prepared in Example 1, add 100g of polyurethane elastomer, dodecylbenzenesulfonate Sodium phosphate 15g, octylphenol polyoxyethylene ether (OP-10) 4g, silicon dioxide 5g, dicumyl peroxide 2g, water 30g, stir and mix evenly through a powerful...

Embodiment 3

[0044] Prepare novel high-resilience load-bearing foam material according to the following steps:

[0045] (1) Preparation of expandable melamine formaldehyde resin: In a 5L stirred reactor, add 1023g of water, 1350g of paraformaldehyde, 1890g of melamine, and 106g of sodium metabisulfite, adjust the pH to 8.5-9 with triethanolamine, and react at a constant temperature of 95°C for 112min. The obtained solid content is 76.5%, and the methylol content is 22.7% of resin gross weight expandable melamine formaldehyde resin, and this resin has certain reactivity;

[0046] (2) Preparation of expandable melamine formaldehyde resin-elastomer emulsion: in a constant temperature water bath at 30°C, take 1000g of expandable melamine formaldehyde resin prepared in Example 1, add 80g of liquid silicone rubber, dodecylbenzenesulfonate Sodium phosphate 18g, alkyl polyoxyethylene ether (AEO-9) 2g, white carbon black 15g, di-tert-butyl peroxide 2g, water 20g, mix evenly through the high-speed s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com