multifunctional protective shoes

A protective shoe and multi-functional technology, applied in the field of rubber, can solve problems such as difficult to coordinate performance and comfort, cannot be applied to chemical accident sites, and affect the work efficiency of staff, so as to achieve excellent physical and mechanical properties and improve processing and operation performance , Improve the appearance of the sole

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

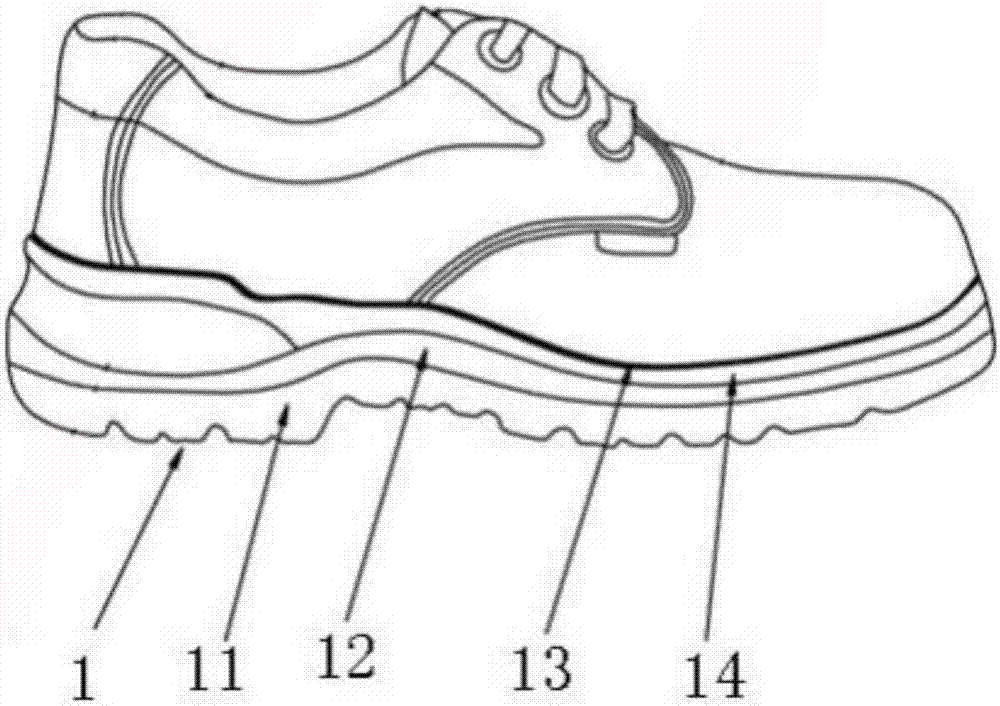

[0018] The multifunctional protective footwear of this embodiment comprises a sole 1, and the sole 1 includes an insulating layer bottom 11, an insulating layer upper bottom 12, and an elastic buffer layer 14 arranged under the insole 13 from bottom to top. The surface is distributed with molded anti-skid lines formed by a combination of isosceles right triangles and obtuse triangles in section; the design of anti-slip lines has a good effect on bearing the vertical and horizontal sliding forces of momentum, and the generally selected angle indices are 45°, 60°, and 120° °, 135°; the elastic buffer layer 14 can be an elastic rubber layer, a sponge layer or an elastic plastic layer; the upper bottom 12 of the insulating layer, the lower bottom 11 of the insulating layer and the elastic buffer layer 14 can all play a good insulating effect; The raw material of the lower bottom 11 of the insulating layer includes the following components in parts by weight: 50 parts of neoprene ru...

Embodiment 2

[0026] The multifunctional protective footwear of this embodiment comprises a sole 1, and the sole 1 includes an insulating layer lower bottom 11, an insulating layer upper bottom 12 and an elastic cushioning layer 14 arranged under the insole 13 from bottom to top, and the insulating lower bottom outer The surface is distributed with molded anti-slip lines formed by a combination of isosceles right triangle and obtuse triangle in section, and the bottom material of the insulating layer includes the following components by weight:

[0027] 60 parts of neoprene rubber, 50 parts of nitrile rubber, 20 parts of styrene-butadiene rubber, 1 part of composite accelerator, 6 parts of organic montmorillonite, N-methylene carboxyl-2-benzothiazole sulfenamide 0.5 parts, 1 part of sulfur, 3 parts of high aromatic oil, 0.1 part of 1,2-ethylene thiourea, 4 parts of mica powder, 10 parts of low-temperature calcined kaolin, 1 part of diethylene glycol, 0.5 parts of anti-aging agent, liquid eth...

Embodiment 3

[0035] In the multifunctional protective shoes of this embodiment, the bottom material of the insulating layer includes the following components by weight:

[0036] 50 parts of neoprene rubber, 50 parts of nitrile rubber, 10 parts of styrene-butadiene rubber, 3 parts of composite accelerator, 6 parts of organic montmorillonite, N-methylene carboxyl-2-benzothiazole sulfenamide 1.5 parts, 1 part of sulfur, 8 parts of high aromatic oil, 0.1 part of 1,2-ethylene thiourea, 8 parts of mica powder, 10 parts of low-temperature calcined kaolin, 3 parts of diethylene glycol, 0.5 parts of anti-aging agent, liquid ethylene- 1.5 parts of propylene-terpolymer, 0.1 part of flame retardant; The composite accelerator is N-oxydiethylenethiocarbamoyl-N'-oxydiethylenesulfenamide, accelerator TMTD, Mixture of Accelerator DM and Accelerator M.

[0037] In the present embodiment, the dosage ratio of N-oxydiethylenethiocarbamoyl-N'-oxydiethylenesulfenamide, accelerator TMTD, accelerator DM and accel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com