Method for treating waste water generated in glyphosate production process

A treatment method, glyphosate technology, which is applied in the treatment of industrial wastewater and the field of wastewater treatment, can solve the problems of secondary pollution, low investment and operation costs, etc., and achieve less loss, low investment and operation costs, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

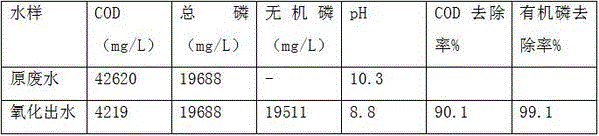

Embodiment 1

[0040] A treatment method for waste water produced in the production of glyphosate, comprising the following process steps:

[0041] A. Dry-mix the adsorption powder material, modified material and organic binder evenly to obtain a mixture;

[0042] B. Add the required amount of acid solution to the mixture, wet mixing and kneading fully to obtain a kneaded product;

[0043] C. Prepare cylindrical or spherical carrier preforms by kneading the mixture through an extrusion pelletizer or a granulator;

[0044] D, the carrier preform is dried at 80°C and roasted at 500°C to obtain a catalyst carrier;

[0045] E, one or two or more precious metal salts in arbitrary proportions in ruthenium, rhodium and palladium are made into impregnation solution;

[0046] F. Using the impregnation method to load the impregnation solution on the catalyst carrier to obtain a catalyst precursor, dry and reduce the catalyst precursor to obtain a finished catalyst, and then fill the finished catalys...

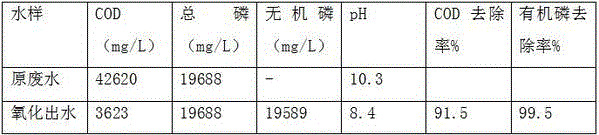

Embodiment 2

[0049] A treatment method for waste water produced in the production of glyphosate, comprising the following process steps:

[0050] A. Dry-mix the adsorption powder material, modified material and organic binder evenly to obtain a mixture;

[0051] B. Add the required amount of acid solution to the mixture, wet mixing and kneading fully to obtain a kneaded product;

[0052] C. Prepare cylindrical or spherical carrier preforms by kneading the mixture through an extrusion pelletizer or a granulator;

[0053] D, the carrier preform is dried at 120°C and calcined at 800°C to obtain a catalyst carrier;

[0054] E, one or two or more precious metal salts in arbitrary proportions in ruthenium, rhodium and palladium are made into impregnation solution;

[0055] F. Using the impregnation method to load the impregnation solution on the catalyst carrier to obtain a catalyst precursor, dry and reduce the catalyst precursor to obtain a finished catalyst, and then fill the finished catal...

Embodiment 3

[0058] A treatment method for waste water produced in the production of glyphosate, comprising the following process steps:

[0059] A. Dry-mix the adsorption powder material, modified material and organic binder evenly to obtain a mixture;

[0060] B. Add the required amount of acid solution to the mixture, wet mixing and kneading fully to obtain a kneaded product;

[0061] C. Prepare cylindrical or spherical carrier preforms by kneading the mixture through an extrusion pelletizer or a granulator;

[0062] D, the carrier preform is dried at 100°C and roasted at 650°C to obtain a catalyst carrier;

[0063] E, one or two or more precious metal salts in arbitrary proportions in ruthenium, rhodium and palladium are made into impregnation solution;

[0064] F. Using the impregnation method to load the impregnation solution on the catalyst carrier to obtain a catalyst precursor, dry and reduce the catalyst precursor to obtain a finished catalyst, and then fill the finished cataly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com