A method for adjusting the length of tungsten oxide nanorods by oxygen

A technology of tungsten oxide and nanorods, which is applied in the field of preparation of tungsten-based nanomaterials technology, can solve the problems affecting the structure and performance of tungsten carbide, and the easy growth of tungsten carbide particles, so as to reduce the secondary agglomeration phenomenon and avoid secondary The effect of reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

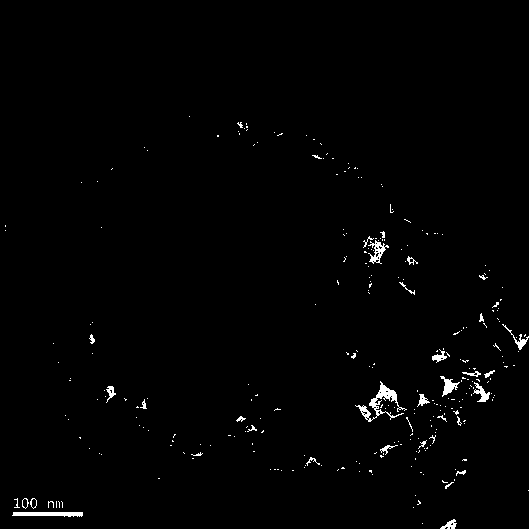

Embodiment 1

[0022]Soak 12 mg of carbon nanotubes with a diameter of 30-200 nm and a layer number of 20-30 in nitric acid, reflux at 100 °C under constant temperature stirring, and after drying, disperse in 100 mL of ethylene glycol and ultrasonically disperse for 24 hours. Obtain a uniformly dispersed carbon nanotube ethylene glycol suspension A with a concentration of 0.01 mol / L; completely dissolve sodium tungstate in 100 mL deionized water to obtain a clear sodium tungstate solution B with a concentration of 0.1 mol / L; solution Add B into solution A, and mix it uniformly under the action of a constant temperature magnetic stirrer, then add an appropriate amount of hydrochloric acid dropwise to adjust the pH value of the solution to 1; reflux for 10 h under the condition of a constant temperature oil bath at 140°C, Then carry out vacuum filtration and washing, the drying temperature is 110 ℃, and the holding time is 2 h; obtain the rod-shaped composite C of carbon nanotubes and tungstic ...

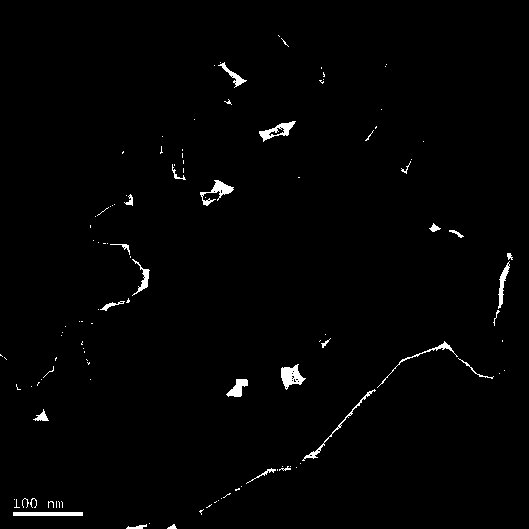

Embodiment 2

[0024] Soak 12 mg of carbon nanotubes with a diameter of 30-200 nm and a layer number of 20-30 in nitric acid, reflux at 100 °C under constant temperature stirring, dry and disperse in 100 mL of ethylene glycol, and ultrasonically disperse for 24 hours to obtain Uniformly dispersed carbon nanotube ethylene glycol suspension A with a concentration of 0.01 mol / L; completely dissolve sodium tungstate in 100 mL deionized water to obtain a clear sodium tungstate solution B with a concentration of 0.1 mol / L; solution B Add it into solution A, mix it evenly under the action of a constant temperature magnetic stirrer, then add an appropriate amount of hydrochloric acid dropwise to it, and adjust the pH value of the solution to 1; reflux for 10 h under the condition of a constant temperature oil bath at 140 °C, and then Vacuum filtration and washing were carried out, the drying temperature was 110 °C, and the holding time was 2 h; the rod-shaped composite C of carbon nanotubes and tungs...

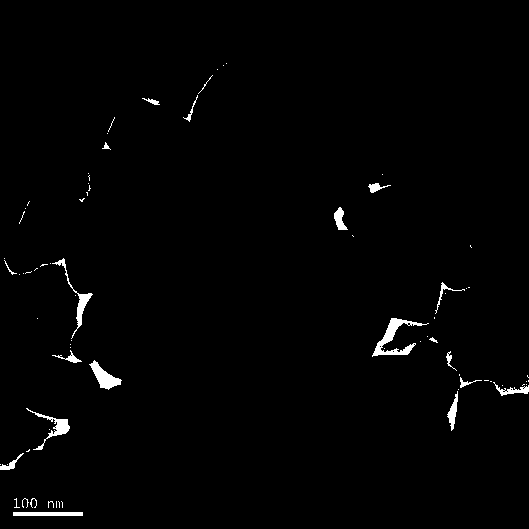

Embodiment 3

[0026] Soak 12 mg of carbon nanotubes with a diameter of 15-150 nm and layers of 10-20 layers in nitric acid, reflux at 130 °C under constant temperature stirring, dry, disperse in 100 mL of ethylene glycol, and ultrasonically disperse for 24 hours to obtain Uniformly dispersed carbon nanotube ethylene glycol suspension A with a concentration of 0.01 mol / L; completely dissolve sodium tungstate in 100 mL of deionized water and ethylene glycol mixture to obtain a clear concentration of 0.2 mol / L tungsten Sodium acid solution B; solution B is added to solution A, under the action of ultrasonic waves, mix it evenly, and then add an appropriate amount of hydrochloric acid to it, and adjust the pH value of the solution to 3; reflux under the condition of a constant temperature oil bath at 120°C 6 h, then carry out vacuum filtration and washing, the drying temperature is 100 ℃, and the holding time is 2 h; obtain the rod-shaped composite C of carbon nanotubes and tungstic acid; spread...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com