Method for hydrothermal technology synthesis of calcium sulfate hemihydrates powder particles

A technology of calcium sulfate hemihydrate and hydrothermal method, which is applied in the field of material science, can solve the problems of inability to obtain gypsum hemihydrate gypsum raw materials, complex crystal transformation process, and difficult particle size control, so as to achieve fluidity and dispersion Excellent, reproducible, time-consuming results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

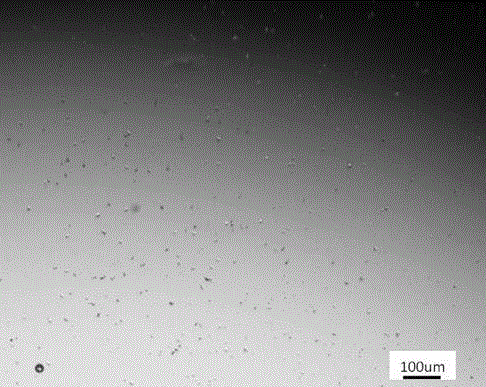

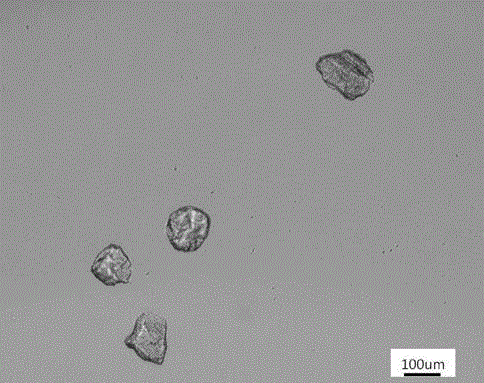

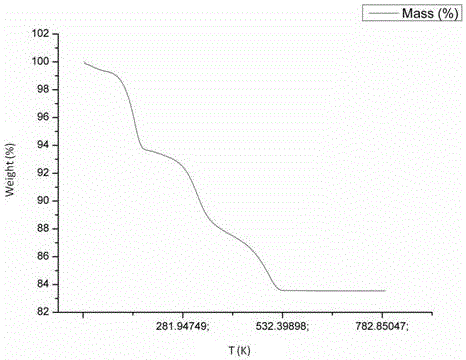

[0024] The method for synthesizing calcium sulfate hemihydrate powder particles by hydrothermal method in the embodiment of the present invention is as follows: (1) Weigh 2 mol of calcium chloride and 2 mol of sodium sulfate, add them to 500 ml of deionized water, and ultrasonically disperse 30min, ultrasonic power 400W; (2) Weigh 2mol polyvinyl alcohol, add it into 100ml deionized water, ultrasonically disperse for 10min, ultrasonic power 400W; (3) Weigh 2mol polyvinylpyrrolidone, add it into 100ml deionized water In water, ultrasonically disperse for 10 minutes, and the ultrasonic power is 400W; (4) Add the solution obtained in steps (2) and (3) dropwise to the solution obtained in step (1), and continue to stir and mix for 30 minutes; (5) Add the solution obtained in step (4) ) The mixed solution obtained was transferred to a hydrothermal reaction kettle, and hydrothermally reacted at 180°C for 12 hours; (6) The reaction product obtained in step (5) was centrifuged at 4000rp...

Embodiment 2

[0027] The method for synthesizing calcium sulfate hemihydrate powder particles by hydrothermal method in the embodiment of the present invention, the specific steps are as follows: (1) Weigh 1 mol of calcium chloride and 1 mol of sodium sulfate, add them to 300ml of deionized water, and ultrasonically disperse 20min, ultrasonic power 200W; (2) Weigh 1mol polyvinyl alcohol, add it into 50ml deionized water, ultrasonically disperse for 10min, ultrasonic power 200W; (3) Weigh 1mol polyvinylpyrrolidone, add it into 50ml deionized water In water, ultrasonically disperse for 10 minutes, and the ultrasonic power is 200W; (4) Add the solution obtained in steps (2) and (3) dropwise to the solution obtained in step (1), and continue to stir and mix for 20 minutes; (5) Add the solution obtained in step (4) ) The mixed solution obtained was transferred to a hydrothermal reaction kettle, and hydrothermally reacted at 160°C for 6 hours; (6) The reaction product obtained in step (5) was cent...

Embodiment 3

[0030] The method for synthesizing calcium sulfate hemihydrate powder particles by hydrothermal method in the embodiment of the present invention, the specific steps are as follows: (1) Weigh 1 mmol of calcium chloride and 1 mmol of sodium sulfate, add them to 5 ml of deionized water, and ultrasonically disperse 10min, ultrasonic power 100W; (2) Weigh 1mmol polyvinyl alcohol, add it into 5ml deionized water, ultrasonically disperse for 10min, ultrasonic power 100W; (3) Weigh 1mmol polyvinylpyrrolidone, add it into 5ml deionized water In water, ultrasonically disperse for 10 minutes, and the ultrasonic power is 100W; (4) Add the solution obtained in steps (2) and (3) dropwise to the solution obtained in step (1), and continue to mix mechanically for 5 minutes; (5) Add the solution obtained in step (4) ) The mixed solution obtained was transferred to a hydrothermal reaction kettle, and hydrothermally reacted at 160°C for 6 hours; (6) The reaction product obtained in step (5) was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com