Bio-ene charcoal material and preparation method thereof

A technology of carbon materials and biomass raw materials, applied in the field of bio-alkene carbon materials and its preparation, can solve the problems of difficult industrialization and high production costs, and achieve the effects of narrow distribution range, developed pores, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

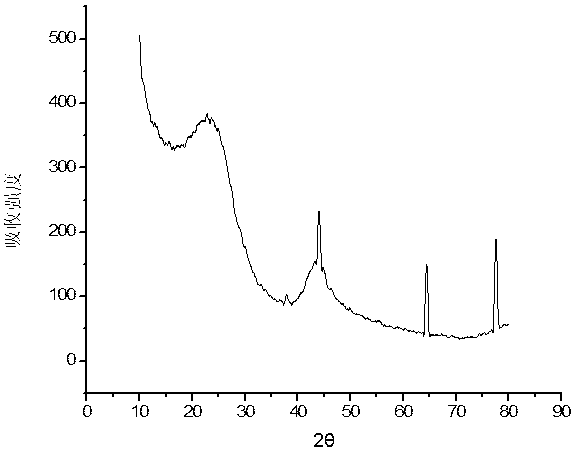

Image

Examples

Embodiment 1

[0036] Coconut shells are screened, dried and crushed to make 50-300 mesh powdered coconut shells for later use;

[0037] After mixing the mixed aqueous solution of powdered coconut shell, phosphoric acid and ferrous sulfate in a ratio of 1:4 by weight, the temperature is 25°C and soaked for 110 hours; the H 3 PO 4 The mixed aqueous solution with sulfate is prepared by mixing phosphoric acid, ferrous sulfate and an appropriate amount of water. The H in the solution 3 PO 4 The content is 3wt%, FeSO 4 The content is 5wt%;

[0038] After filtering and drying the impregnated powdered coconut shell, activate it for 150 minutes under the protection of nitrogen atmosphere at a temperature of 200°C;

[0039] The activated powdery coconut shell is heated up to 1000°C in 20 minutes under the protection of nitrogen atmosphere, kept for 40 minutes, and then heated to 1200°C for 10 minutes, kept for 30 minutes to make it catalyzed and carbonized to obtain an intermediate product;

[0...

Embodiment 2

[0044] Bamboo is screened, dried, and crushed to make 50-300 mesh powdered bamboo for later use;

[0045] After mixing the mixed aqueous solution of powdery bamboo with phosphoric acid and cobalt sulfate in a ratio of 1:1 by weight, immerse for 150 hours at a temperature of 20°C; the mixed aqueous solution of phosphoric acid and cobalt sulfate is composed of phosphoric acid, cobalt sulfate and an appropriate It is prepared after mixing the water, the H in the mixed aqueous solution 3 PO 4 The content is 5wt%, CoSO 4 The content is 4wt%;

[0046] After filtering and drying the impregnated powdery bamboo, activate it for 60 minutes under nitrogen atmosphere protection at a temperature of 500°C;

[0047] The activated powdery bamboo is heated to 1000°C for 60 minutes and kept for 10 minutes under the protection of nitrogen atmosphere, and then heated to 1400°C for 40 minutes and kept for 10 minutes to make it catalyzed and carbonized to obtain an intermediate product;

[00...

Embodiment 3

[0052] Camellia oleifera shells are screened, dried and crushed to make 50-300 mesh powdered camellia oleifera shells for later use;

[0053] After mixing the mixed aqueous solution of powdered camellia oleifera husk with phosphoric acid and nickel sulfate in a ratio of 1:20 by weight, soaking for 12 hours at a temperature of 60°C; the H 3 PO 4 The mixed aqueous solution with nickel sulfate is prepared by mixing phosphoric acid, nickel sulfate and an appropriate amount of water. The mixed aqueous solution contains H 3 PO 4 The content is 1wt%, NiSO 4 The content of is 5wt%;

[0054] After filtering and drying the impregnated powdered camellia oleifera husk, activate it for 100 minutes under the protection of a nitrogen atmosphere at a temperature of 300°C;

[0055] The activated biomass raw material is heated to 1000°C in 40 minutes under the protection of nitrogen atmosphere, kept at 25 minutes, and then heated to 1300°C for 25 minutes, kept at 20 minutes to catalyze ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| iodine adsorption value | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com