Graphene oxide-loaded nano-iron material with magnetic separation properties in underground medium and preparation method thereof

An underground medium, graphene technology, applied in chemical instruments and methods, alkali metal oxide/hydroxide, polluted groundwater/leachate treatment, etc., can solve serious environmental toxicity, loss of reducing ability, migration performance, etc. It can reduce the toxic effect, improve the migration ability, and enhance the dispersion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

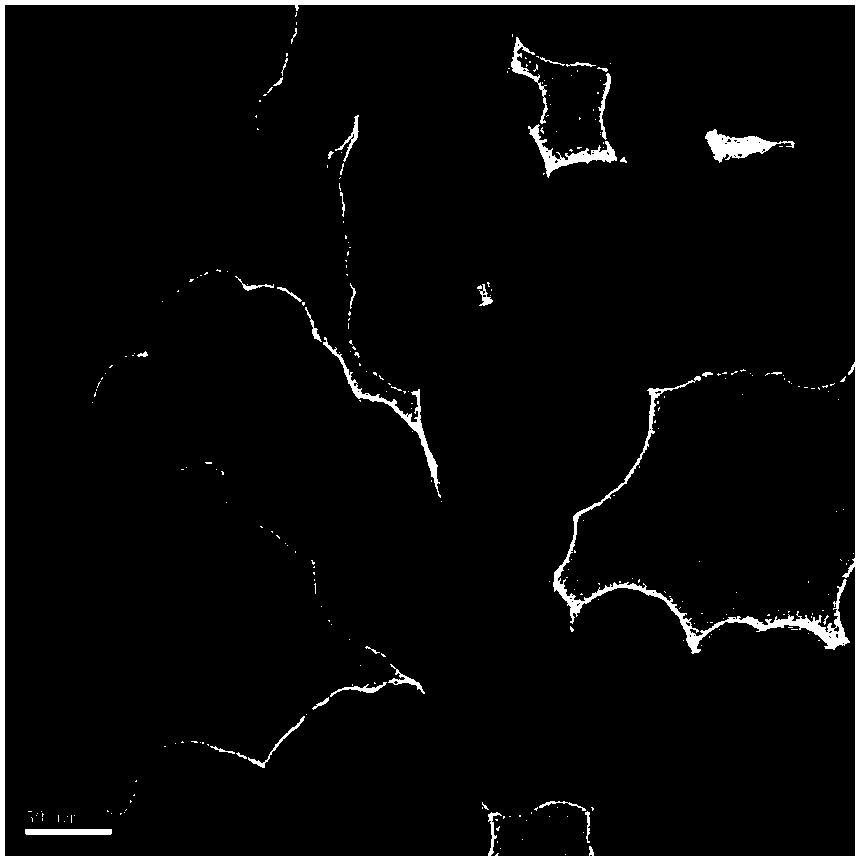

[0036] A. Dissolve 0.06g of dry GO (prepared by the improved Hummers method) in 1000 mL of deionized water and sonicate for 2 hours to obtain a GO suspension;

[0037] B. Add 7.11g ferrous chloride (FeCl 2 ·4H 2 O) 500mL solution was slowly injected into the GO suspension, and mechanically stirred for 30min;

[0038] C. Take 19.3g potassium borohydride (KBH 4 )Dissolved in deionized water to prepare 0.715mol / L KBH 4 Solution, add 1mol / L NaOH solution to the solution to adjust the pH to 9; under the protection of nitrogen, use the high-performance liquid reduction method and use the peristaltic pump to reduce the KBH 4 The solution was added to the mixed solution obtained in step B. After the addition was completed, the stirring was continued for 4 hours, and the Fe 2+ Reduced to Fe 0 , The dropping rate is 5mL / min, KBH in the solution after dropping 4 With FeCl 2 ·4H 2 The molar ratio of O is 10:1;

[0039] D. Use a magnet to collect the product prepared in step C, that is, graphene o...

Embodiment 2

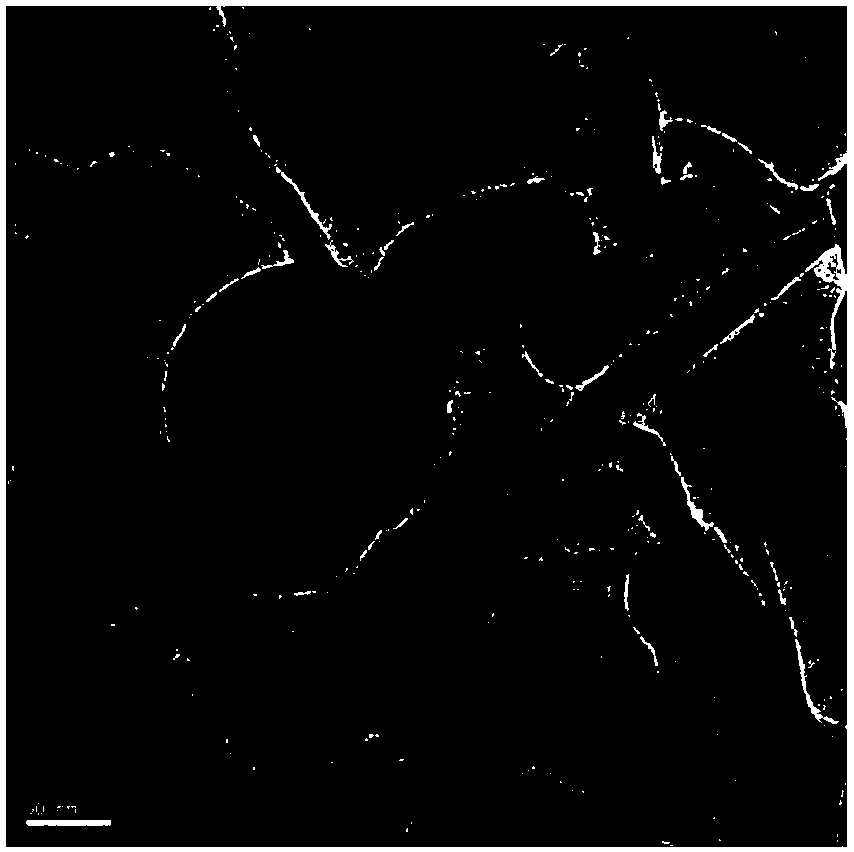

[0041] A. Dissolve 0.12 g of dry GO (prepared by the improved Hummers method) in 1000 mL of deionized water and sonicate for 4 hours to obtain a GO suspension;

[0042] B. Add 9.93g ferrous sulfate (FeSO 4 ·7H 2 O) 500mL solution was slowly injected into the GO suspension, and mechanically stirred for 30min;

[0043] C. Take 19.3g KBH 4 Dissolved in deionized water to obtain 0.715mol / L KBH 4 Solution, add 1mol / L NaOH solution to the solution to adjust the pH value to 9.5; under the protection of nitrogen, use the high-performance liquid reduction method and use the peristaltic pump to reduce the KBH 4 The solution was added to the mixed solution obtained in step B. After the addition was completed, the stirring was continued for 4 hours, and the Fe 2+ Reduced to Fe 0 , The dropping rate is 6mL / min, KBH in the solution after dropping 4 With FeCl 2 ·4H 2 The molar ratio of O is 10:1;

[0044] D. Use a magnet to collect the product prepared in step C, that is, graphene oxide loaded nano-...

Embodiment 3

[0046] A. Dissolve 0.30 g of dry GO (prepared by the improved Hummers method) in 1000 mL of deionized water for 4 hours to obtain a GO suspension;

[0047] B. Then will contain 10.29g ferrous nitrate Fe(NO 3 ) 2 ·6H 2 A 500mL solution of O was slowly injected into the GO suspension and stirred mechanically for 30 minutes;

[0048] C. Take 13.6g of sodium borohydride (NaBH 4 ) Dissolved in deionized water to prepare 0.715mol / L NaBH 4 Solution, add 1mol / L NaOH solution to the solution to adjust the pH value to 10; under the protection of inert gas, use high-performance liquid reduction method to use peristaltic pump 4 The solution was added to the mixed solution obtained in step B. After the addition was completed, the stirring was continued for 4 hours, and the Fe 2+ Reduced to Fe 0 , The dropping rate is 5mL / min, and the NaBH in the solution after the addition is complete 4 With Fe(NO 3 ) 2 ·6H 2 The molar ratio of O is 10:1;

[0049] D. Use a magnet to collect the product prepared in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com