Bone tissue engineering scaffold with multi-scale controllable micropore structure and preparation method thereof

A technology of tissue engineering scaffold and bone tissue engineering, which is applied in the field of biomedical materials, can solve the problems such as the inability to realize nanoscale, achieve adjustable mechanical properties, meet biomechanical requirements, and meet the effect of protein adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

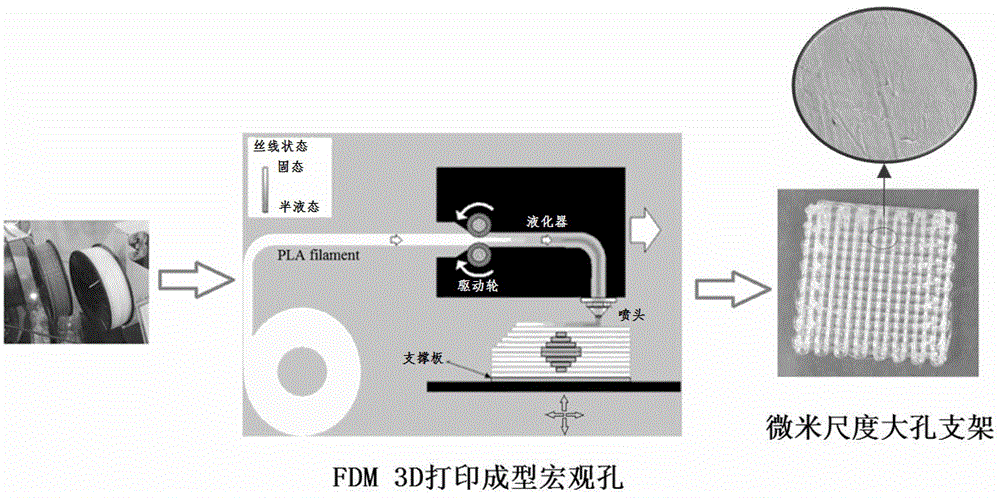

[0043] The biomimetic multi-scale controllable microporous structure bone tissue engineering scaffold was prepared by using the thermoplastic medical polymer material PLA as the raw material. Its production specific steps are as follows:

[0044] 1) Choose Φ1.75mm medical-grade PLA material wire, and form a micron-scale three-dimensional porous tissue engineering scaffold through FDM three-dimensional printing. In the specific printing process, choose a single nozzle with a diameter of Φ0.2mm for printing. The speed is 150mm / s, the design size of the macroscopic holes in the cross-section is 200×200μm orthogonal macropores, and the layer thickness in the vertical direction is 200μm. The final dimension of the formed scaffold is Φ8×6mm, the dimension of the macroscopic pores of the scaffold is about 200×200×200μm, the porosity is about 50%, and the macropores are three-dimensionally interpenetrating and connected, which is isotropic.

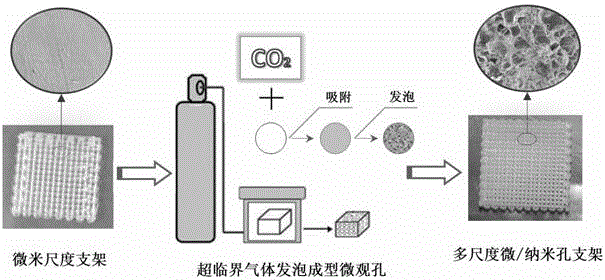

[0045] 2) The three-dimensional macroporo...

Embodiment 2

[0047] Other conditions and processes are the same as those in Example 1, except that a different three-dimensional printing process is used in Step 1. In its specific printing process, a single nozzle with a diameter of Φ0.4mm is selected for printing, the temperature of the nozzle is 200°C, the printing speed is 150mm / s, and the macroscopic holes in the section are designed to be orthogonal large holes with a size of 400×400μm. The layer thickness was 400 μm. The final dimension of the formed scaffold is Φ8×6mm, the dimension of the macroscopic macropores of the scaffold is about 400×400×400μm, the porosity is about 52%, and the macropores are three-dimensionally interpenetrating and connected, which is isotropic. After the supercritical gas foaming process in Step 2 of Example 1, the macroscopic macropore size of the finally formed biomimetic multi-scale microporous structure scaffold is about 420×420×420 μm, and the secondary micro-nano scale micropores formed in the print...

Embodiment 3

[0049] Other conditions and processes are the same as those in Example 1, except that a different three-dimensional printing process is used in Step 1. In the specific printing process, a single nozzle with a diameter of Φ0.4mm is selected for printing, the temperature of the nozzle is 200°C, the printing speed is 150mm / s, and the macroscopic holes in the section are designed to be orthogonal large holes with a size of 600×600μm. The layer thickness was 400 μm. The final dimension of the formed scaffold is Φ8×6mm, the dimension of the macroscopic macropores of the scaffold is about 600×600×400μm, the porosity is about 66%, and the macropores are three-dimensionally interpenetrating and connected, which is isotropic. After the supercritical gas foaming process in Step 2 of Example 1, the macroscopic and macropore size of the finally formed biomimetic multi-scale microporous structure scaffold is about 620×620×420 μm, and the secondary micro-nano scale micropores formed in the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com