Mushroom bacterial strain preparation method

A technology for strain preparation and shiitake mushrooms, applied in botany equipment and methods, mushroom cultivation, fertilizer mixture, etc., can solve the problems of long germination period of branch strains, time-consuming and labor-intensive seeding of sawdust, low incidence of strains, etc. Achieve the effects of inhibiting the growth of miscellaneous bacteria, prolonging the shelf life, and reducing the incidence rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

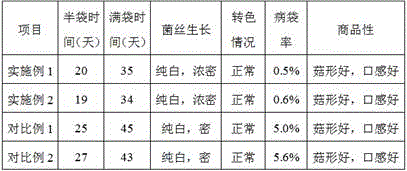

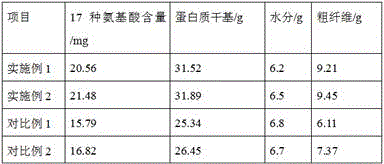

Examples

Embodiment 1

[0021] A preparation method of shiitake mushroom strain:

[0022] (1) Choose Amorpha fragrans branches with a diameter of 0.5 cm and a length of 6 cm, boil them in boiling water for 20 minutes, put them into a pool containing chondroitin sulfate waste liquid and soak for 36 hours, and the ratio of chondroitin sulfate waste liquid to water in the pool is 1 : 10, chondroitin sulfate waste liquid is the waste liquid that enzymatic method produces chondroitin and produces, contains polysaccharide 200mg / L, amino acid 5000mg / L, salt 20mg / L, rinses, drains, and keeping branch moisture is 50%;

[0023] (2) Put the branches, bran and water in a mass ratio of 4:1:0.2, put them into a 17cm*36cm folding bag, stir evenly, the branches are covered with bran, and sterilize under the conditions of 0.15Mpa, 120 Sterilize at ℃ for 2 hours;

[0024] (3) Inoculate grain strains to 7% of the weight of the branches, and after the branches are covered with mycelium, continue to cultivate for 20 day...

Embodiment 2

[0028] A preparation method of shiitake mushroom strain:

[0029] (1) Choose oak branches with a diameter of 0.5 cm and a length of 8 cm, put them in a pool and boil them for 30 minutes, then soak them in a pool containing chondroitin sulfate waste liquid for 36 hours. The ratio is 1:50, the chondroitin sulfate waste liquid is the waste liquid produced by enzymatic hydrolysis of chondroitin, containing 500mg / L of polysaccharide, 10000mg / L of amino acid, 50mg / L of salt, rinsed, drained, and the water content of the branches is kept at 60%;

[0030] (2) Put the branches, bran and water in a mass ratio of 4:1:0.2, put them into a 17cm*36cm folding bag, stir evenly, the branches are covered with bran, and sterilize under the conditions of 0.15Mpa, 120 Sterilize at ℃ for 3 hours;

[0031] (3) Inoculate grain strains to 7% of the weight of the branches, and after the branches are covered with mycelium, continue to cultivate for 30 days;

[0032] (4) Oak sawdust, sweet-scented osma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com