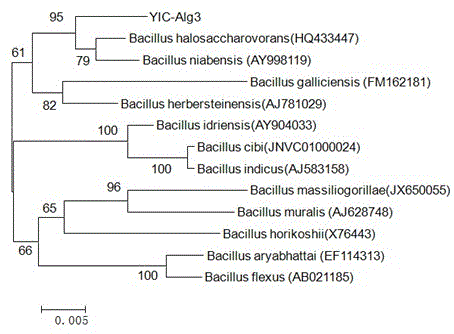

Bacillus saccharophila used for degrading alginic acid, and application method thereof

A technology of Bacillus saccharophilus and alginic acid, which is applied in the field of Bacillus saccharophilus, can solve problems such as difficulty in meeting industrial production requirements, poor controllability of the fermentation process, and difficulty in guaranteeing product quality, and achieve remarkable product efficacy and stable and reliable fermentation process. The effect of control and short fermentation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

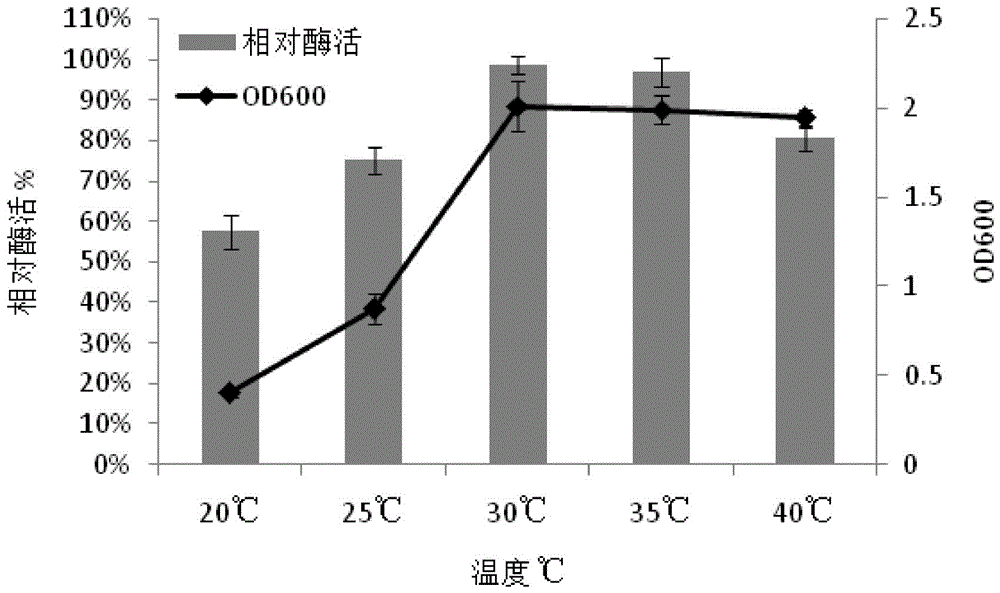

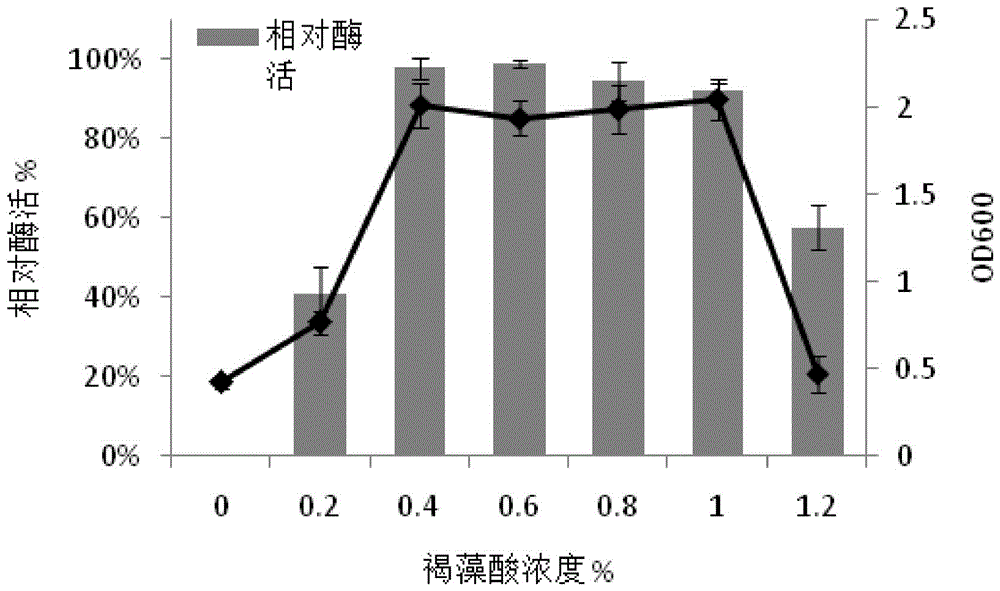

Embodiment 1

[0051] Grinding the washed and dried fresh sargassum into 50-60 mesh powder;

[0052] Seaweed powder and water are put into a fermenter according to the mass ratio of 2:100, and sterilized at 115°C for 35 minutes to obtain product A; and prepare seed liquid: inoculate the above-mentioned Bacillus saccharophilus YIC~Alg3 into the liquid medium Cultivate for 20 hours; the preservation number of the Bacillus saccharophilus YIC~Alg3 is CGMCC No12155; the liquid medium is: sodium alginate 5g, ammonium sulfate 5g, magnesium sulfate 1g, dipotassium hydrogenphosphate 2g, ferrous sulfate 0.01 g. A mixture of 20 g of agar and 1000 ml of distilled water, pH 7.2-7.4; the volume ratio of Bacillus saccharophilus YIC-Alg3 to the culture medium is 2:100. Add the seed liquid to product A, wherein the mass ratio of seed liquid to product A is 1:100 to obtain product B; ferment product B at a temperature of 20°C and a pH of 5.5 to 6.0, and the fermentation time is 7 days; collecting the ferment...

Embodiment 2

[0054] The washed and dried fresh copper algae and fresh sargassum are compounded according to the mass ratio of 1:1, and ground into 50-60 mesh powder;

[0055] Seaweed powder and water are put into a fermenter according to the mass ratio of 4:100, and sterilized at 115°C for 25 minutes to obtain product A; and prepare seed liquid: inoculate the Bacillus saccharophilus YIC~Alg3 into the liquid medium Cultivate for 22 hours; the preservation number of the Bacillus saccharophilus YIC~Alg3 is CGMCC No12155; the liquid medium is: sodium alginate 5g, ammonium sulfate 5g, magnesium sulfate 1g, dipotassium hydrogen phosphate 2g, ferrous sulfate 0.01 g. A mixture of 20 g of agar and 1000 ml of distilled water, pH 7.2-7.4; the volume ratio of Bacillus saccharophilus YIC-Alg3 to the culture medium is 5:100. The seed liquid is added to product A, wherein the mass ratio of seed liquid to product A is 5:100, and product B is obtained; product B is fermented at a temperature of 25°C and a ...

Embodiment 3

[0057] Grinding the washed and dried fresh Sargassum into 50-60 mesh powder;

[0058] Seaweed powder and water are loaded into a fermenter according to the mass ratio of 6:100, and sterilized at 125°C for 35 minutes to obtain product A; and prepare seed liquid: inoculate the Bacillus saccharophilus YIC~Alg3 into the liquid medium Cultivate for 24 hours; the preservation number of the Bacillus saccharophilus YIC~Alg3 is CGMCC No12155; the liquid medium is: sodium alginate 5g, ammonium sulfate 5g, magnesium sulfate 1g, dipotassium hydrogen phosphate 2g, ferrous sulfate 0.01 g. A mixture of 20 g of agar and 1000 ml of distilled water, pH 7.2-7.4; the volume ratio of Bacillus saccharophilus YIC-Alg3 to the culture medium is 8:100. Add the seed liquid to product A, wherein the mass ratio of seed liquid to product A is 4:100 to obtain product B; ferment product B at a temperature of 30°C and a pH of 7 to 7.5, and the fermentation time is 9 days ; Collecting the fermentation liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com