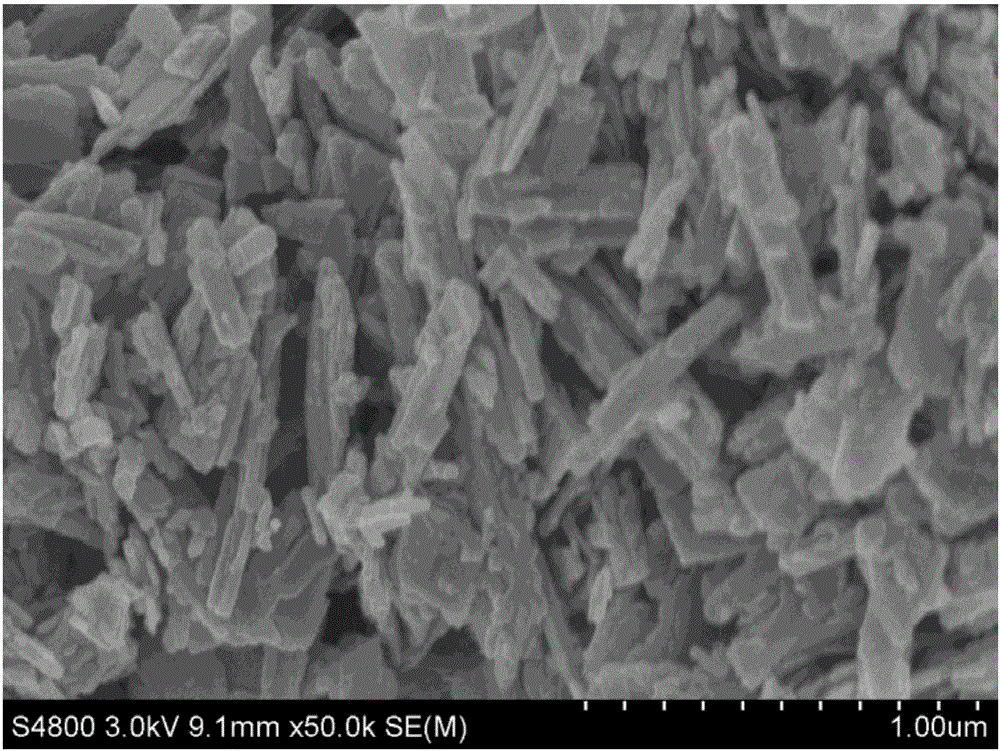

Preparation method and application of nanometer rod-shaped V3S4

A technology of nanorods and nanomaterials, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve rare problems and achieve high crystallinity, excellent performance, and uniform chemical composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A preparation method of nanorod-shaped vanadium tetrasulfide, comprising the following steps:

[0026] Step 1: Take 10-20mL of ethylene glycol and pour it into 30-50mL of deionized water, and magnetically stir for 10-30min to obtain solution A. Then weigh a certain amount of V 2 o 5 Dissolve in solution A and stir magnetically for 30-60 minutes to obtain vanadium source solution B, wherein the concentration of vanadium source is 0.01-0.10 mol / L. The ethylene glycol is replaced with one or more of oxalic acid, ethanol and isopropanol.

[0027] Step 2: Pour the prepared solution B into the reaction polytetrafluoroethylene liner, put the liner into the outer kettle, and place it in the homogeneous reactor after being fixed. Then, under the conditions that the rotation speed is controlled at 5-50 r / min, the filling ratio of the reactor is controlled at 40-70%, and the reaction temperature is controlled at 120-200° C., the temperature is kept for 12-48 hours. The reactio...

Embodiment 1

[0034] Step 1: Take 15mL of ethylene glycol and pour it into 45mL of deionized water, and magnetically stir for 10min to obtain solution A. Then weigh 0.8gV 2 o 5 Dissolve in solution A and stir magnetically for 30 minutes to obtain solution B, wherein the concentration of vanadium source is 0.02mol / L.

[0035] Step 2: Pour the prepared solution B into the reaction polytetrafluoroethylene liner, put the liner into the outer kettle, and place it in the homogeneous reactor after being fixed. Then, the temperature is kept at 180° C. for 24 hours at a rotating speed of 5 to 10 r / min, a filling ratio of the reactor of 60 percent, and a reaction temperature of 180° C.

[0036] Step 3: After the hydrothermal reaction is completed, cool the reactor to room temperature naturally, take out the reaction liquid and wash it with deionized water for 3 times and with absolute ethanol for 3 times. Then the washed samples were collected and frozen at a cold trap temperature of -70 to -65°C ...

Embodiment 2

[0044] Step 1: Take 10mL of ethylene glycol and pour it into 30mL of deionized water, and magnetically stir for 15min to obtain solution A. Then weigh 0.5gV 2 o 5 Dissolve in solution A and stir magnetically for 40 minutes to obtain solution B, wherein the concentration of vanadium source is 0.01mol / L.

[0045] Step 2: Pour the prepared solution B into the reaction polytetrafluoroethylene liner, put the liner into the outer kettle, and place it in the homogeneous reactor after being fixed. Then, keep the temperature for 48 hours under the condition that the rotating speed is 10-20 r / min, the filling ratio of the reactor is 40%, and the reaction temperature is 120°C.

[0046] Step 3: After the hydrothermal reaction is completed, cool down the reactor naturally to room temperature, take out the reaction solution and wash it twice with deionized water and twice with absolute ethanol. Then collect the washed samples and freeze them for 12 to 24 hours at a cold trap temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com