Manufacturing method of epidermis for Tillandsia epidermis structure observation

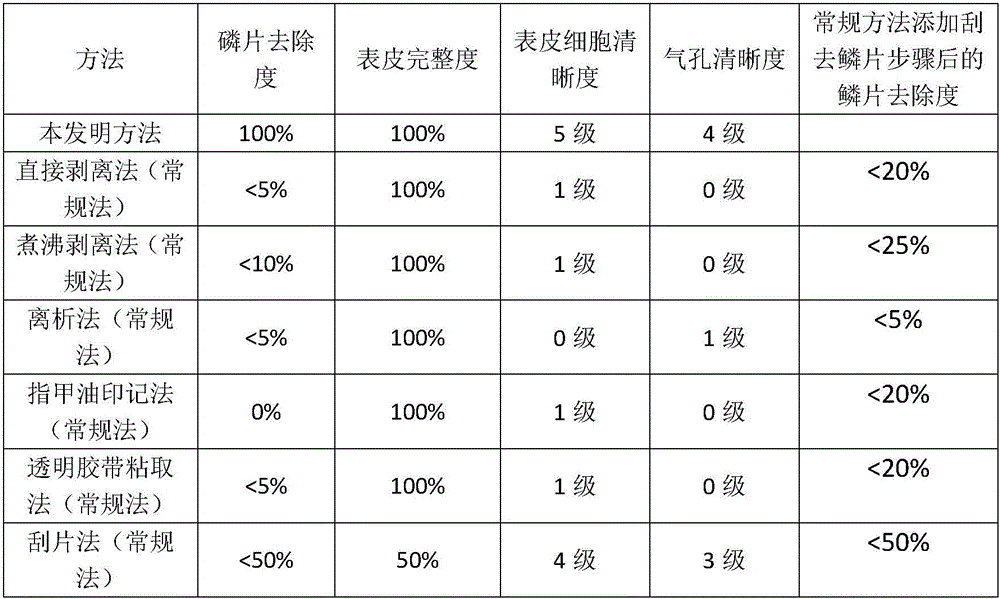

A technology for aerial Tillandsia and plant epidermis, which is applied in the field of epidermis production for the observation of aerial Tillandsia plant epidermis structure, and can solve the problems of inability to obtain ideal observation materials for aerial Tillandsia plant leaf epidermis, low scale removal, and epidermal cell clarity To improve the definition of epidermal cells and pores, the effect is outstanding, and the method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Take fresh mature leaves of "Velutina" and soak them in 3% hydrogen peroxide solution for 2.0 hours at room temperature.

[0026] 2. Take out the leaves after soaking, and select an area of 2cm x 2cm on the upper surface and the middle of the lower surface, respectively, and use a single-sided blade to scrape off the surface scales. At this time, the scales are easy to scrape off and not easy to scratch the epidermis.

[0027] 3. Cut off the part of the blade where the scales have been scraped off.

[0028] 4. Use tweezers to tear off the epidermis on the upper or lower surface of the cut blade, and at this time, the complete epidermis without damage can be torn off.

[0029] 5. Wash the peeled off skin layer with clean water.

[0030] 6. Immerse the torn epidermis in a drop of water on a glass slide, flatten, cover slip and carry out routine staining.

[0031] Through the above steps, the clear epidermal cell structure of the leaves of "Velutina" can be observed...

Embodiment 2

[0033] All the methods are the same as in Example 1, except that the species of the aerial Tillandsia plant is "Bawang", and step 1 is soaked with 1% hydrogen peroxide solution for 2.0 hours.

Embodiment 3

[0035] All the methods are the same as in Example 1, except that the species of the aerial Tillandsia genus is "Bronze Air Flower", and in step 1, soak with 5% hydrogen peroxide solution for 0.5 hour.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com