10-80-mm high-strength low-crack sensitive steel SX780CF for large-scale hydroelectric project and preparation method thereof

A hydropower engineering and high-strength technology, which is applied in the field of medium and heavy plate production, can solve the problems of reducing the yield of steel products, reducing mechanical properties, and affecting the surface quality of steel products, and achieves good austenite uniformity and fine austenite structure , the effect of preventing excessive grain coarsening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

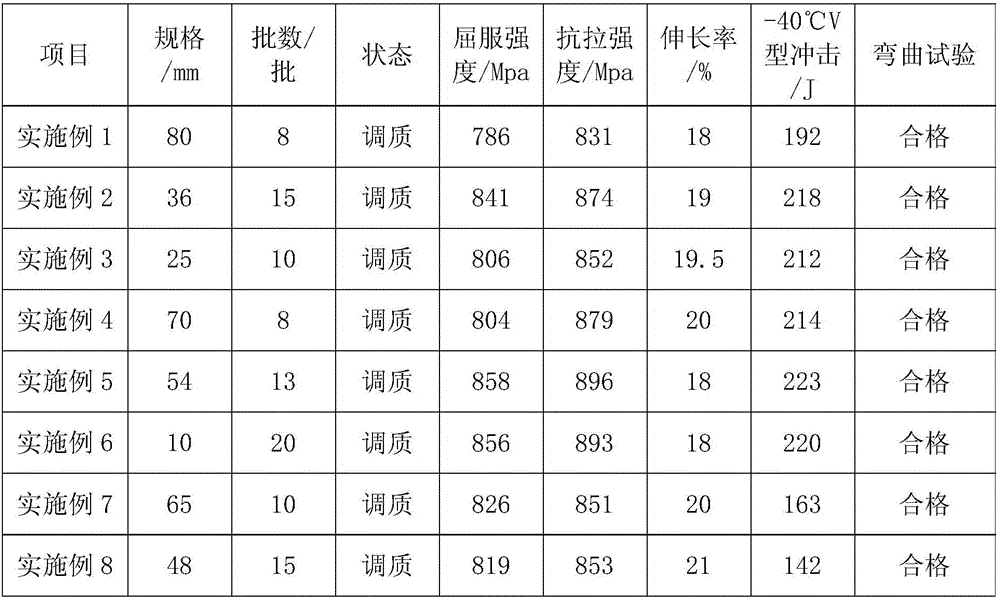

Examples

Embodiment 1

[0035] A high-strength and low-crack-sensitivity steel SX780CF for 10-80mm large-scale hydropower projects, including the following chemical components in mass percentages (unit, wt%): C: 0.05, Si: 0.2, Mn: 1.0, P: 0.010, S: 0.001, Ni: 0.9, Cu: 0.15, Cr: 0.4, Mo: 0.4, V+Nb+Ti: 0.1, Als: 0.015, the balance is Fe and residual elements; the Ceq of the high-strength and low-crack-sensitive steel SX780CF is 0.52, and Pcm is 0.10.

[0036] Its preparation method includes molten iron desulfurization, converter smelting, VD steelmaking, LF refining, VD vacuum refining, continuous casting, billet cutting, surface temperature spraying of high-temperature anti-oxidation coating, heating, high-pressure water descaling, controlled rolling and controlled cooling , pile cooling, flaw detection, quenching and tempering heat treatment, performance inspection, cutting, storage;

[0037] The converter smelting process: at the end of the converter, the tapping temperature is 1630°C, the C is 0.0...

Embodiment 2

[0048] A high-strength and low-crack-sensitive steel SX780CF for 10-80mm large-scale hydropower projects, including the following chemical components in mass percentages (unit, wt%): C: 0.09, Si: 0.1, Mn: 1.3, P: 0.002, S: 0.005, Ni: 0.6, Cu: 0.25, Cr: 0.2, Mo: 0.6, V+Nb+Ti: 0.05, Als: 0.045, the balance is Fe and residual elements; the Ceq of the high-strength and low-crack-sensitive steel SX780CF is 0.30 and Pcm is 0.25.

[0049] Its preparation method includes molten iron desulfurization, converter smelting, VD steelmaking, LF refining, VD vacuum refining, continuous casting, billet cutting, surface temperature spraying of high-temperature anti-oxidation coating, heating, high-pressure water descaling, controlled rolling and controlled cooling , pile cooling, flaw detection, quenching and tempering heat treatment, performance inspection, cutting, storage;

[0050] The converter smelting process: at the end of the converter, the tapping temperature is 1640°C, the C is 0.09%...

Embodiment 3

[0061] A high-strength and low-crack-sensitivity steel SX780CF for 10-80mm large-scale hydropower projects, including the following chemical components in mass percentages (unit, wt%): C: 0.07, Si: 0.18, Mn: 1.2, P: 0.006, S: 0.002, Ni: 0.8, Cu: 0.17, Cr: 0.25, Mo: 0.45, V+Nb+Ti: 0.06, Als: 0.028, the balance is Fe and residual elements; the Ceq of the high-strength and low-crack-sensitive steel SX780CF is 0.33, and Pcm is 0.18.

[0062]Its preparation method includes molten iron desulfurization, converter smelting, VD steelmaking, LF refining, VD vacuum refining, continuous casting, billet cutting, surface temperature spraying of high-temperature anti-oxidation coating, heating, high-pressure water descaling, controlled rolling and controlled cooling , pile cooling, flaw detection, quenching and tempering heat treatment, performance inspection, cutting, storage;

[0063] The converter smelting process: at the end of the converter, the tapping temperature is 1635°C, the C is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com