Anti-ultraviolet, heat-insulating and radiation-proof PET membrane and preparation method thereof

An anti-ultraviolet and anti-radiation technology, applied in the field of polymer materials, can solve problems affecting film transmittance and haze, affecting visual effects, etc., and achieve excellent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

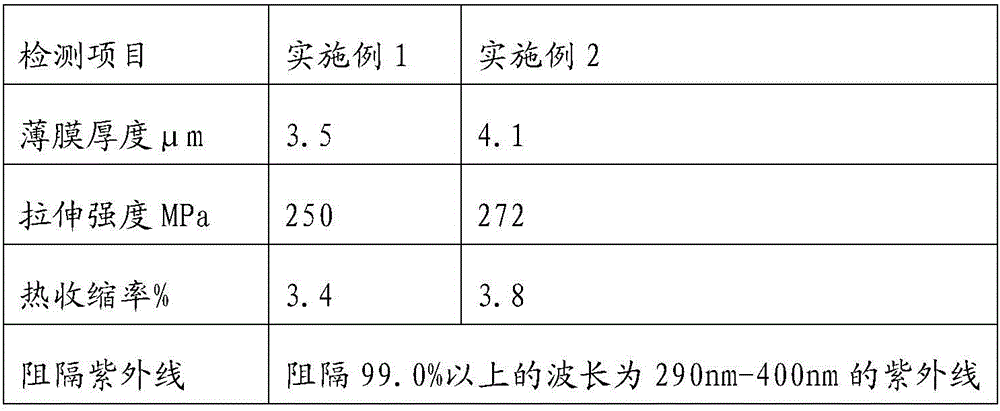

Examples

Embodiment 1

[0027] 1) Take the raw materials in the following parts by weight:

[0028] 100 parts of PET polyester chips, 10 parts of methoxypropyl acetate, 8 parts of ethyl acrylate, bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate (Tinuvin770) 2 2 parts, 2 parts of bisbenzoxazole, 5 parts of nano-titanium dioxide, 4 parts of RC-E60 non-silicon release agent, 0.9 parts of HANKINS NCP-2, 2-(2-hydroxy-3-tert-butyl-5-methyl 10 parts of phenyl)-5-chlorobenzotriazole (UV-326);

[0029] 2) Add PET polyester chips, nano-titanium dioxide, RC-E60 silicon-free release agent and HANKINS NCP-2 into the reaction kettle, and stir at 105°C for 30 minutes at a speed of 150 rpm to obtain a mixture;

[0030] 3) add methoxypropyl acetate, ethyl acrylate, two (2,2,6,6-tetramethyl-4-piperidinyl) sebacate and bisbenzoxazole in the reactor, The temperature in the reactor rises to 300°C, the pressure drops below 90pa, reacts for 3 hours to obtain a polymer melt, extrudes the polymer melt, cuts into pellets, an...

Embodiment 2

[0032] 1) Take the raw materials in the following parts by weight:

[0033] 80 parts of PET polyester chips, 7 parts of methoxypropyl acetate, 5 parts of ethyl acrylate, bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate (Tinuvin770)8 4 parts of bisbenzoxazole, 6 parts of nano-titanium dioxide, 5 parts of RC-E60 silicone-free release agent, 2 parts of HANKINS NCP-2, 2-(2-hydroxy-3-tert-butyl-5-methyl 10 parts of phenyl)-5-chlorobenzotriazole (UV-326);

[0034] 2) Add PET polyester chips, nano-titanium dioxide, RC-E60 silicon-free release agent and HANKINS NCP-2 into the reaction kettle, and stir at 95°C at a speed of 200 rpm for 10 minutes to obtain a mixture;

[0035] 3) add methoxypropyl acetate, ethyl acrylate, two (2,2,6,6-tetramethyl-4-piperidinyl) sebacate and bisbenzoxazole in the reactor, The temperature in the reactor rises to 300°C, the pressure drops below 60pa, reacts for 3 hours to obtain a polymer melt, extrudes the polymer melt, cuts into pellets, and dries at 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com