A vibration membrane treatment method and device for desulfurization wastewater

A technology for desulfurization wastewater and treatment method, which is applied in gaseous effluent wastewater treatment, multi-stage water treatment, water/sewage treatment, etc. The effect of operating cost, realizing harmless treatment and discharge, and saving process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Example 1 Vibrating membrane treatment of desulfurization wastewater

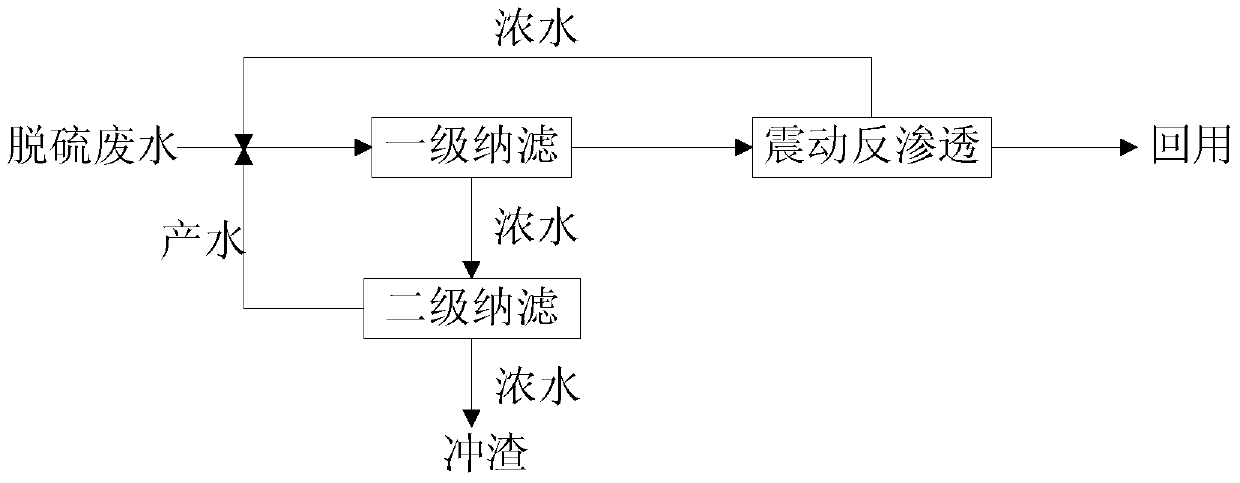

[0046] according to figure 1 The process flow chart in the process of desulfurization wastewater vibration membrane treatment, the specific steps are as follows:

[0047] 1) Pass the desulfurization wastewater into the first vibrating nanofiltration membrane for primary nanofiltration, and the recovery rate of produced water in the primary nanofiltration is 65%;

[0048] 2) Pass the primary concentrated water obtained in step 1) into the second vibrating nanofiltration membrane for secondary nanofiltration, and the recovery rate of product water in the secondary nanofiltration is 57%; the primary product obtained in step 1) is The water is forced into the reverse osmosis membrane to further filter the reverse osmosis concentrated water and reverse osmosis product water, and the reverse osmosis product water is reused to production. 3) return the secondary product water obtained through step 2) to t...

Embodiment 2

[0057] Example 2 Vibrating membrane treatment of desulfurization wastewater

[0058] according to figure 1 The process flow chart in carries out desulfurization wastewater vibration membrane treatment, and concrete steps are as follows:

[0059] 1) Pass the desulfurization wastewater into the first vibrating nanofiltration membrane for primary nanofiltration, and the recovery rate of produced water in the primary nanofiltration is 60%;

[0060] 2) passing the primary concentrated water obtained in step 1) into the second vibrating nanofiltration membrane for secondary nanofiltration, and the recovery rate of produced water in the secondary nanofiltration is 55%;

[0061] The primary product water obtained in step 1) is forced into the reverse osmosis membrane for further filtration to obtain reverse osmosis concentrate water and reverse osmosis product water, and the reverse osmosis product water is reused to production. The recovery rate of product water in reverse osmosis i...

Embodiment 3

[0064] Embodiment 3, desulfurization wastewater vibration membrane treatment

[0065] according to figure 1 The process flow chart in carries out desulfurization wastewater vibration membrane treatment, and concrete steps are as follows:

[0066] 1) Pass the desulfurization wastewater into the first vibrating nanofiltration membrane for primary nanofiltration, and the recovery rate of produced water in the primary nanofiltration is 65%;

[0067] 2) passing the primary concentrated water obtained in step 1) into the second vibrating nanofiltration membrane for secondary nanofiltration, and the recovery rate of produced water in the secondary nanofiltration is 65%;

[0068] The primary product water obtained in step 1) is forced into the reverse osmosis membrane for further filtration to obtain reverse osmosis concentrated water and reverse osmosis product water, and the reverse osmosis product water is reused to production. The recovery rate of reverse osmosis product water is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com