Dynamic purification regenerator of harmful solvent and application thereof

A technology of harmful solvents and regenerators, which is applied in the fields of chemical industry, medicine and fine chemical industry, can solve the problems of small and medium-sized enterprises and laboratories, inconvenient operation, energy waste, etc., and achieve small equipment height, easy operation and fast separation speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

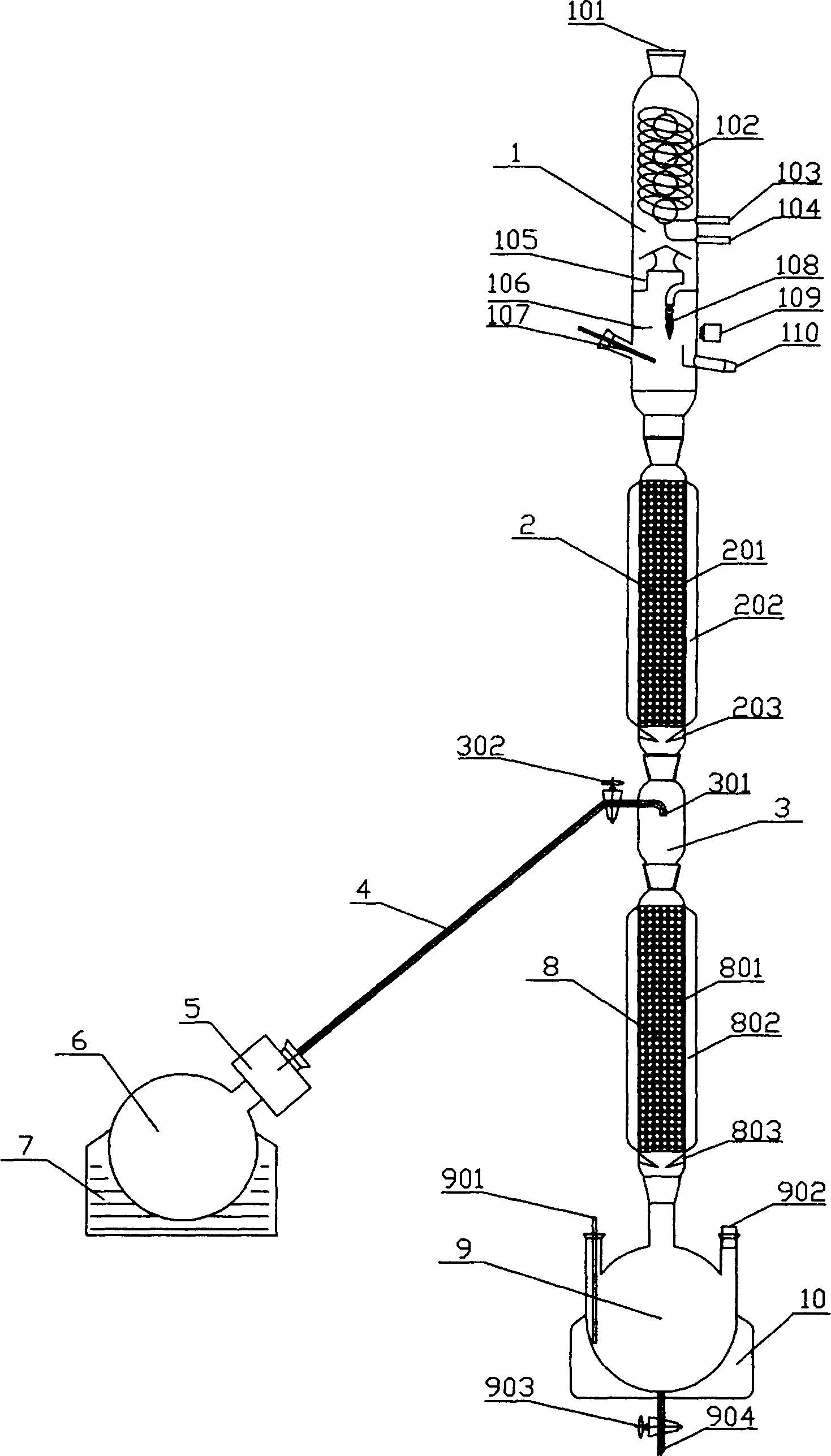

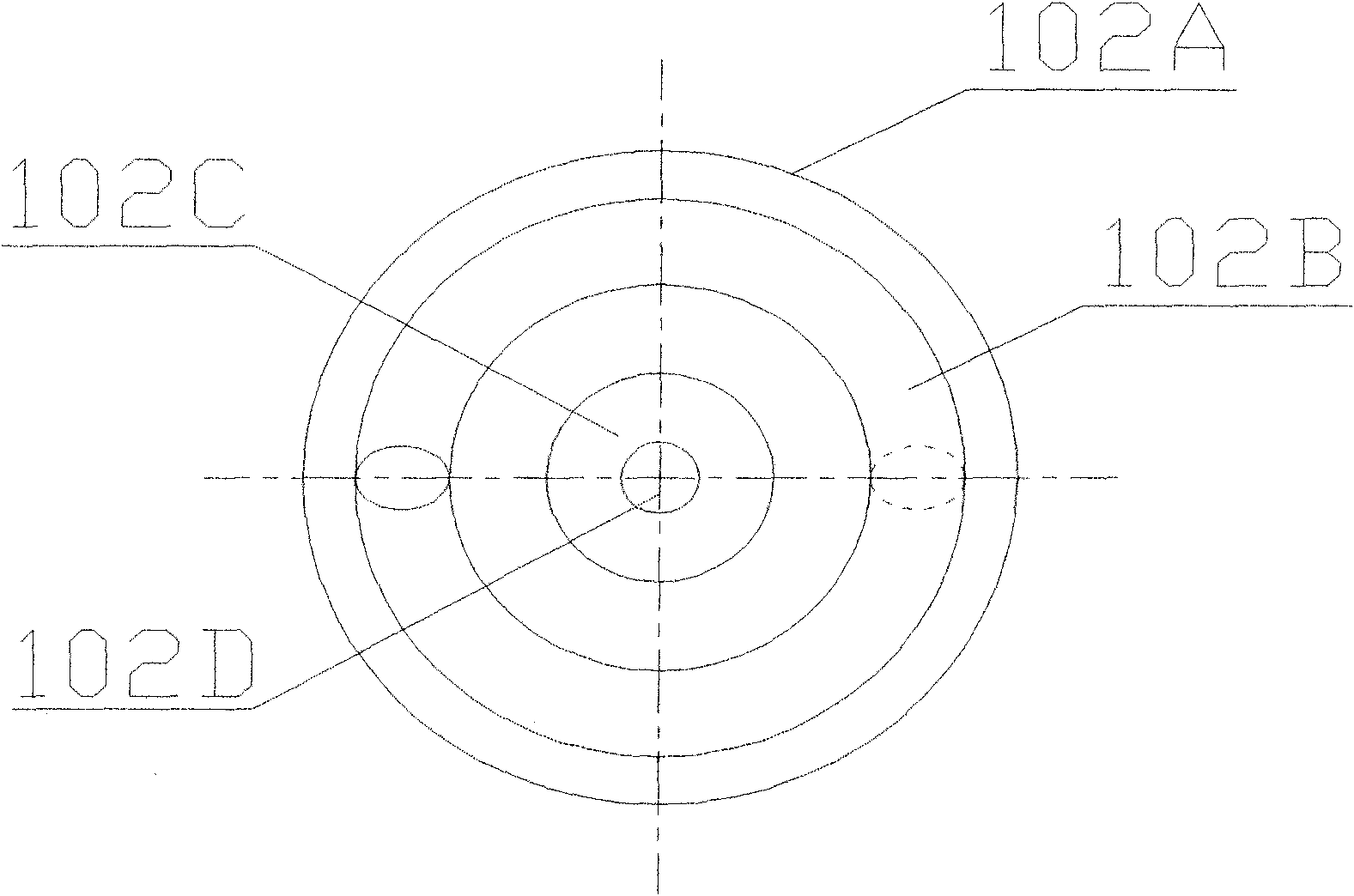

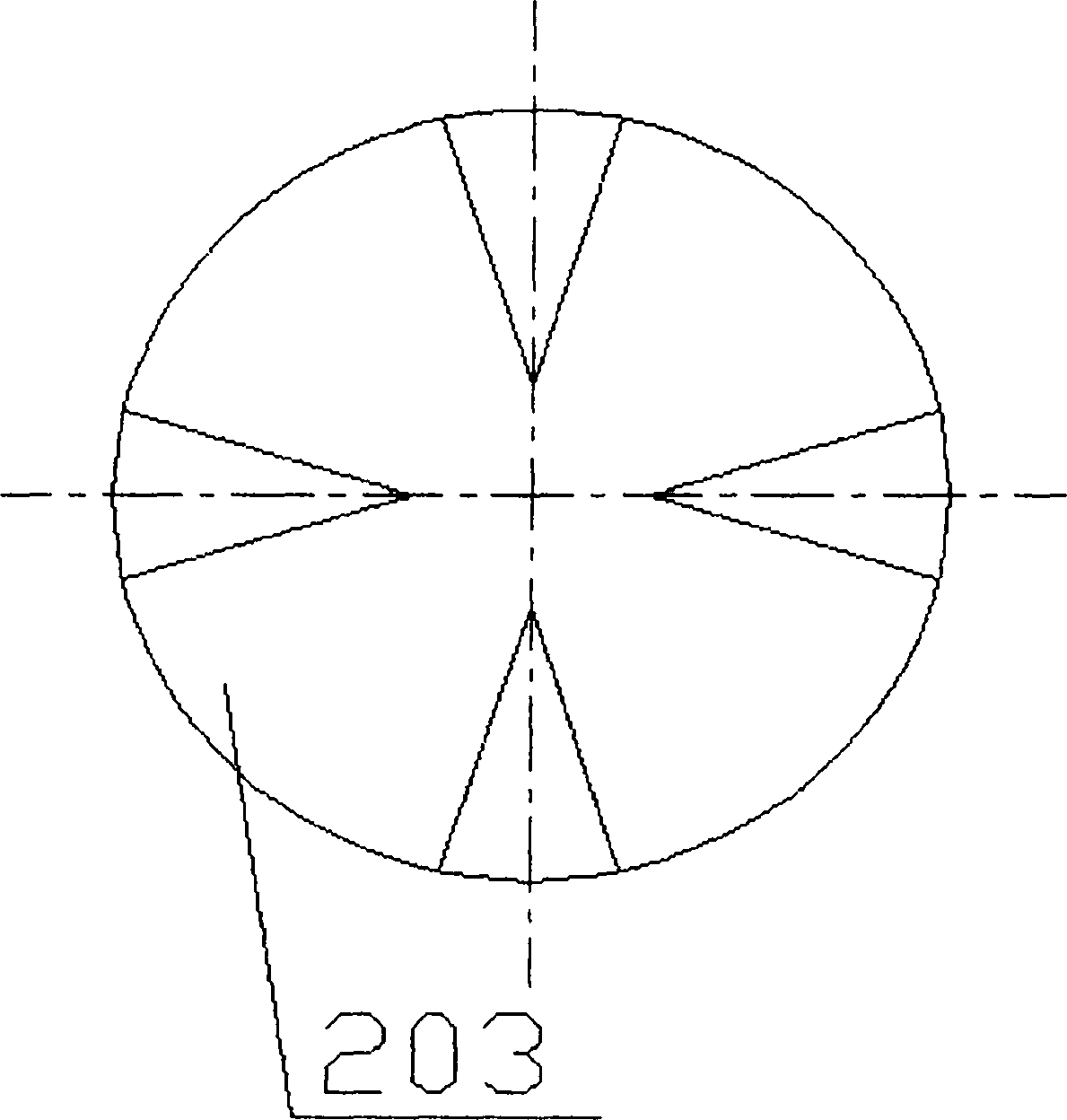

[0015] Such as figure 1 Shown: a kind of instrument of mixed solvent fractionation purification, it comprises tower head condenser, upper fractionation section, feed section in the tower, soft connection, evaporating flask, lower fractionation section, tower kettle: tower head condenser 1 comprises and The pressure stabilizing port 101 connected to the atmosphere, the spherical and serpentine condensing pipe 102, the condensing pipe is provided with a condensed water outlet 103 and a condensed water inlet 104, and a vapor-liquid distributor 105 for contacting the ascending steam with the descending condensate, In order to prevent the baffle 106 from being damaged due to excessive swing of the reflux ratio, the temperature measuring element 107 to monitor the temperature change at the top of the tower, the reflux ratio 108 to control the extraction and reflux, the solenoid valve 109 to control the flow rate of the reflux ratio and the top of the extraction tower The outlet 110 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com