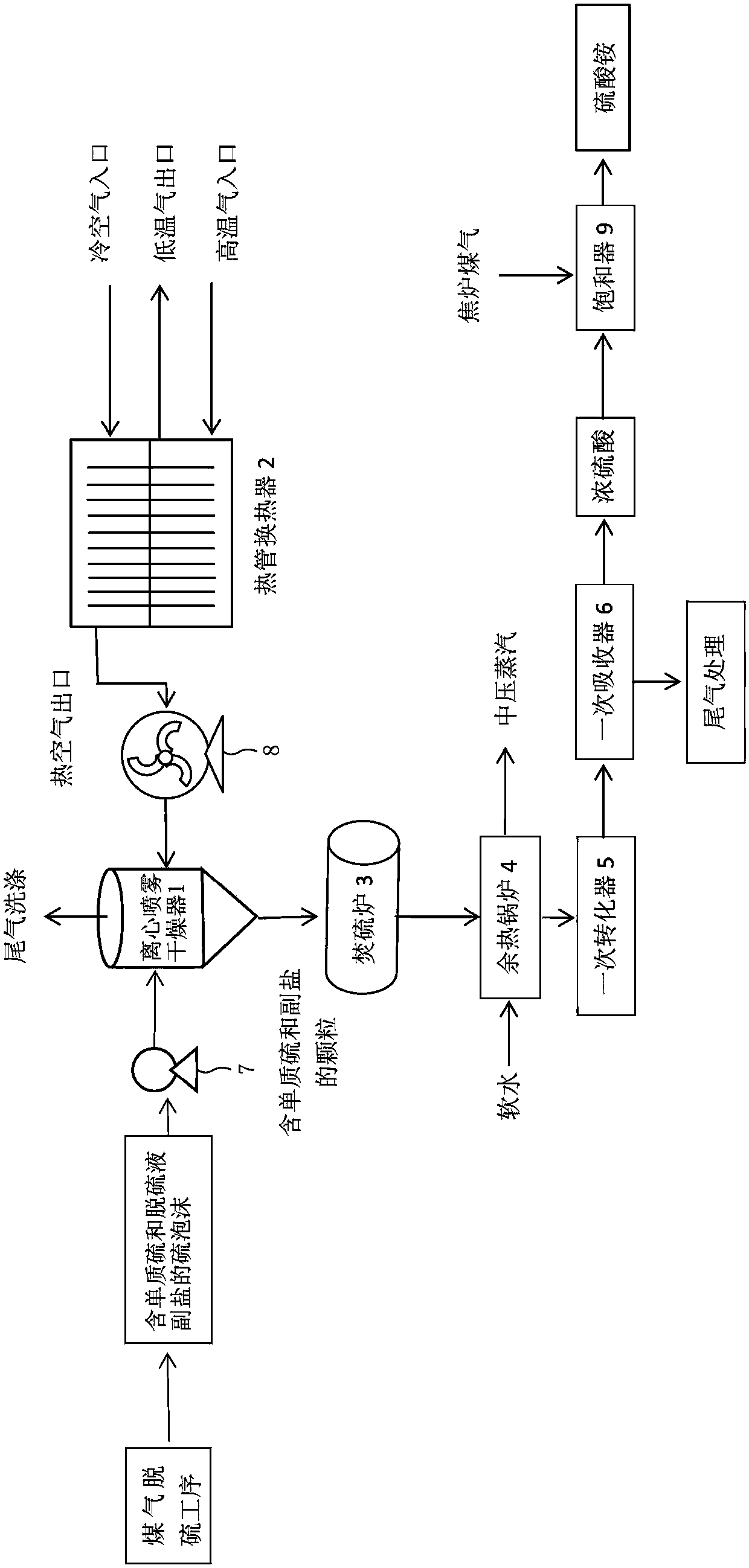

A system and process for comprehensive utilization of coking low-quality sulfur and side salt of desulfurization liquid

A low-quality desulfurization liquid secondary salt technology, applied in the chemical industry, inorganic chemistry, sulfur compounds, etc., can solve problems such as sales difficulties, small product market demand, and large energy consumption, and achieve resource utilization and waste reduction For the treasure of economic benefits, the effect of preventing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Various example embodiments will be described more fully hereinafter with reference to the accompanying drawings, in which example embodiments are shown. Example embodiments may, however, be embodied in many different forms and should not be construed as limited to example embodiments set forth herein. Therefore, the present invention may include all modifications, equivalents, or substitutes included within the concept and technical scope related to the present invention. In describing the embodiments of the present invention, certain detailed descriptions of the prior art will be omitted when it is considered that they would unnecessarily obscure the essence of the present invention.

[0022] The invention provides a system and process for comprehensively utilizing coking low-quality sulfur and auxiliary salt of desulfurization liquid. In the whole process of the present invention, no solid or liquid waste is produced, all waste gas is recovered, treated and purified...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com