Method for deep removal of tin in tellurium-contained solution

A solution and depth technology, applied in the direction of element selenium/tellurium, etc., can solve the problems of decreasing utilization rate of tellurium, underutilization of tellurium resources, difficulty in solid-liquid sedimentation and separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

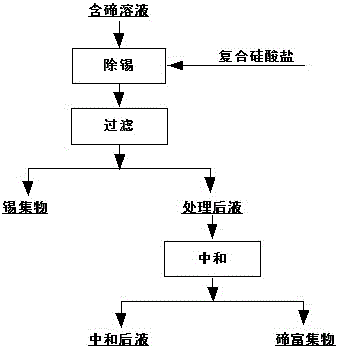

Embodiment 1

[0014] The tellurium-containing liquid produced in copper smelting enterprises also contains a certain amount of tin. During the process of directly entering the tellurium production line to recover tellurium, the content of tin impurities in the tellurium electrolyte will increase, making it difficult to settle and separate the solid and liquid during liquid production. During the process, the anode slime will stick to the tank wall and the pole plate. As a result, the utilization rate of tellurium is reduced, and tellurium resources are not fully utilized. Add tricalcium silicate additive to the tellurium-containing solution, control the mass ratio of additive to tin in the solution to 0.2:1, react at 50°C, and react for 2 hours. After the deposition is completed, filter and neutralize the obtained filtrate with 50g / l sulfuric acid, and filter to obtain a tellurium enrichment containing more than 60% tellurium, which can be used as a high-quality tellurium raw material to en...

Embodiment 2

[0016] The tellurium-containing liquid produced in copper smelting enterprises also contains a certain amount of tin. During the process of directly entering the tellurium production line to recover tellurium, the content of tin impurities in the tellurium electrolyte will increase, making it difficult to settle and separate the solid and liquid during liquid production. During the process, the anode slime will stick to the tank wall and the pole plate. As a result, the utilization rate of tellurium is reduced, and tellurium resources are not fully utilized. In the solution containing tellurium, add a composite silicate additive, control the mass ratio of the additive to the tin in the solution to 1:1, the reaction temperature is 70°C, and the reaction time is 6 hours. After the deposition is completed, filter and neutralize the obtained filtrate with 70g / l sulfuric acid, and filter to obtain a tellurium enrichment containing more than 60% tellurium, which can be used as a hig...

Embodiment 3

[0018] The tellurium-containing liquid produced in copper smelting enterprises also contains a certain amount of tin. During the process of directly entering the tellurium production line to recover tellurium, the content of tin impurities in the tellurium electrolyte will increase, making it difficult to settle and separate the solid and liquid during liquid production. During the process, the anode slime will stick to the tank wall and the pole plate. As a result, the utilization rate of tellurium is reduced, and tellurium resources are not fully utilized. In the tellurium-containing solution, a composite silicate additive is added, the mass ratio of the additive to the tin in the solution is controlled to be 2:1, the reaction temperature is 90° C., and the reaction time is 12 hours. After the deposition is completed, filter and neutralize the obtained filtrate with 90g / l sulfuric acid, and filter to obtain a tellurium enrichment containing more than 60% tellurium, which can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com