Lightweight anti-glare rearview mirror and manufacturing method thereof

A manufacturing method and a rearview mirror technology are applied in the field of automobile rearview mirrors, which can solve the problems of difficulty in guaranteeing strength, hidden safety hazards, and complexity, and achieve the effects of excellent function, light weight and reduced volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

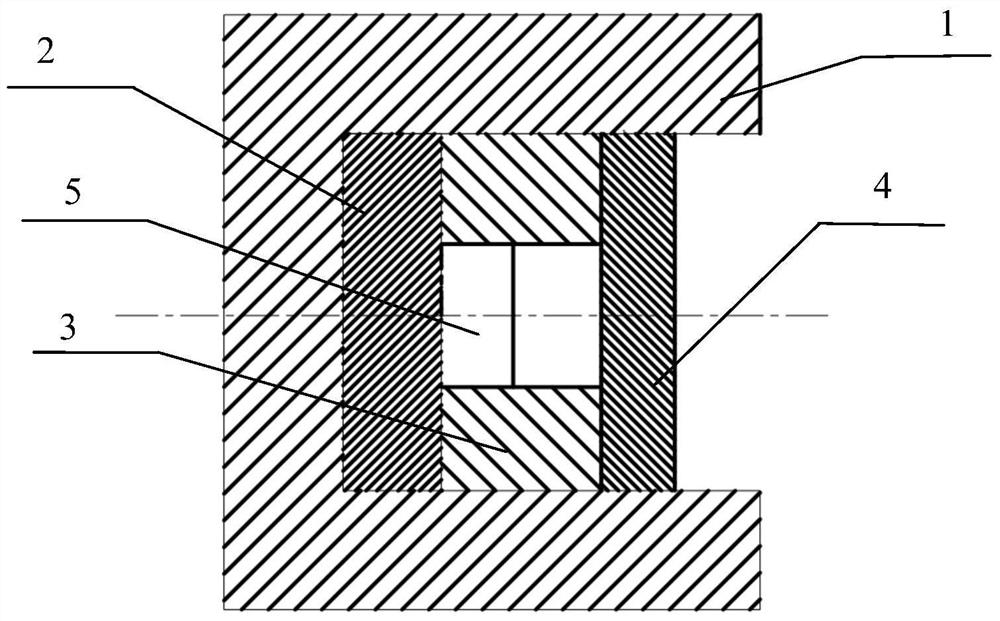

[0035] Reference attached figure 1 , a light-weight anti-glare rearview mirror according to the present invention includes a housing 1, a circuit board 2, a liner 3 and a mirror body 4, and the housing 1, the circuit board 2, the liner 3 and the mirror body The external shape of 4 can be designed and changed according to the overall design of the car. The shell 1 can be made of light metal, such as aluminum alloy, or plastic. The liner 2 is an aluminum alloy core plate wound with carbon fiber. The circuit board 3 is provided with a control chip 5 and a photosensitive element 6 . The control chip 5 is used to drive the liquid crystal layer and control the voltage input to the liquid crystal layer, so as to adjust the light transmission degree of the liquid crystal layer and realize the anti-glare function. The photosensitive element 6 is arranged on the inner side of the circuit board 2, and is used to detect the intensity of the rear light, and the light intensity is judged...

Embodiment 2

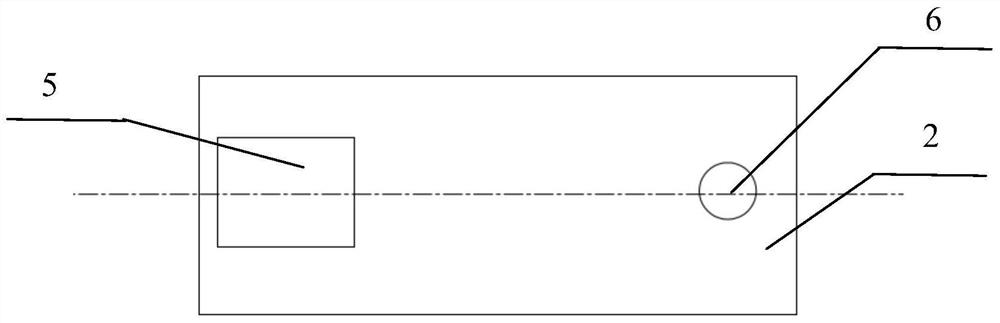

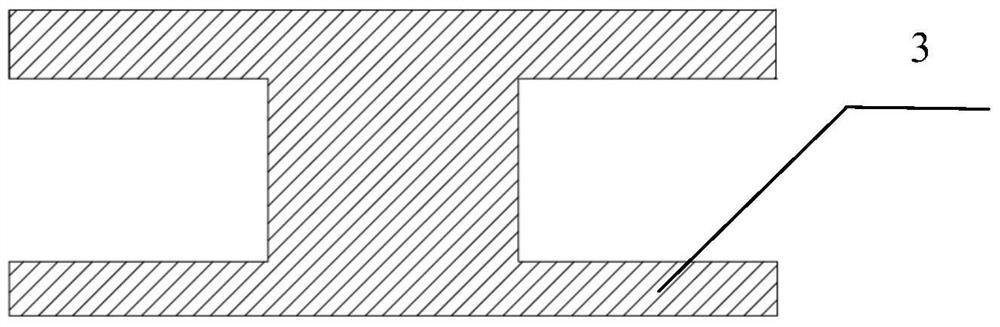

[0037] Reference attached Figure 2-3, a lightweight anti-glare rearview mirror, including a housing 1, a circuit board 2, a lining 3 and a mirror body 4, the outer shape of the housing 1, the circuit board 2, the lining 3 and the mirror body 4 can be Make design changes based on the overall design of the car. The shell 1 can be made of light metal, such as aluminum alloy, or plastic. The liner 2 is an aluminum alloy core plate wound with carbon fiber. Both ends of the liner 2 are provided with gaps, and the circuit board 3 is provided with a control chip 5 and a photosensitive element 6 . The control chip 5 is used to drive the liquid crystal layer and control the voltage input to the liquid crystal layer, so as to adjust the light transmission degree of the liquid crystal layer and realize the anti-glare function. Generally speaking, the more prominent parts on the circuit board are the control chip and the photosensitive element. The gaps at both ends of the liner 3 cor...

Embodiment 3

[0039] A lightweight anti-glare rearview mirror, comprising a housing 1, a circuit board 2, a liner 3 and a mirror body 4, the outer shape of the housing 1, the circuit board 2, the liner 3 and the mirror body 4 can be according to Design changes were made to the overall design of the car. The shell 1 can be made of light metal, such as aluminum alloy, or plastic. The liner 2 is an aluminum alloy core plate wound with carbon fiber. Both ends of the liner 2 are provided with gaps, and the circuit board 3 is provided with a control chip 5 and a photosensitive element 6 . The control chip 5 is used to drive the liquid crystal layer and control the voltage input to the liquid crystal layer, so as to adjust the light transmission degree of the liquid crystal layer and realize the anti-glare function. Generally speaking, the more prominent parts on the circuit board are the control chip and the photosensitive element. The gaps at both ends of the liner 3 correspond to the positio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com