A method for continuous casting ladle to keep molten steel clean

A technology for continuous casting of steel and molten steel, applied in foundry equipment, mechanical cleaning, manufacturing tools, etc., can solve problems such as huge economic losses, and achieve the effects of reducing economic losses, stabilizing variety and quality, and stabilizing steel quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings, but it should be pointed out that the implementation of the present invention is not limited to the following embodiments.

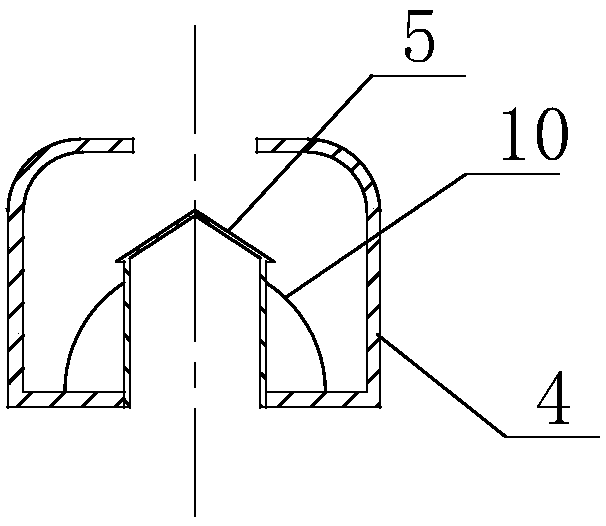

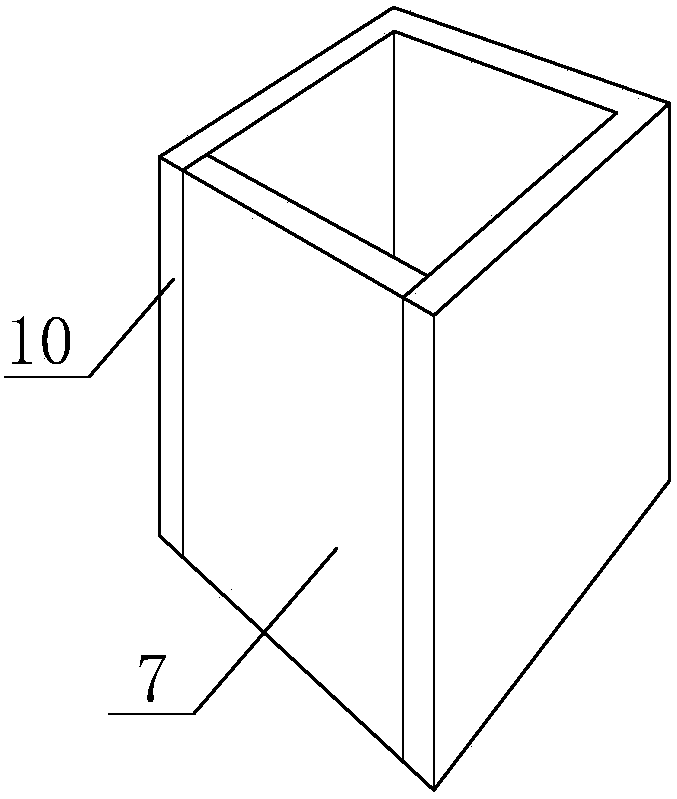

[0037] See Figure 1-Figure 5 , the device for keeping the molten steel 9 clean when the continuous casting ladle 1 is opened, comprising a sliding nozzle 2 arranged at the bottom of the ladle 1, a shroud 3 fixed at the bottom of the ladle 1 and connected with the ladle 1, the upper part of the shroud 3 is connected to the sliding The nozzle 2 is sealed and connected, and also includes a recovery device 4 and a slag separator 6. The recovery device 4 is set under the shroud 3 and does not touch the bottom of the long nozzle 3, leaving a gap in the middle; the slag separator 6 is set on the recovery device 4 Below, the recoverer 4 is composed of a flow steel pipe, an opening cap 5, and an annular groove. The flow steel pipe is fixed in the middle ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com