Nano-silver composite textile catalyst and application thereof

A nano-catalyst and nano-silver technology, applied in catalytic reactions, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc., can solve harsh conditions, unsuitable for large-scale applications, post-processing hazards and other problems, to achieve the effect of easy preparation, good catalytic effect and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1: Preparation and standard of nano-silver composite textile catalyst

[0014] The nano-silver composite textile catalyst was prepared by a one-step in situ growth synthesis method. White cotton textiles were first washed in deionized water and dried. Take 43 grams of washed cotton and place it in a mixed aqueous solution of silver nitrate and 3-aminopropyltriethoxysilane (water temperature: 60°C, AgNO 3 Concentration 2.72mM), soak for 10 minutes; take out the sample and wash it with deionized water, then put the sample in 5mM sodium borohydride aqueous solution at room temperature, soak for 10 minutes, it can be observed that the cotton cloth gradually changes from white to yellow, It shows the formation of nano-silver particles on the textile, and then the nano-silver composite textile catalyst can be obtained through the subsequent washing and drying process.

[0015] Such as figure 1 As shown, in the synthesized nano-silver composite textile, the nano-...

Embodiment 2

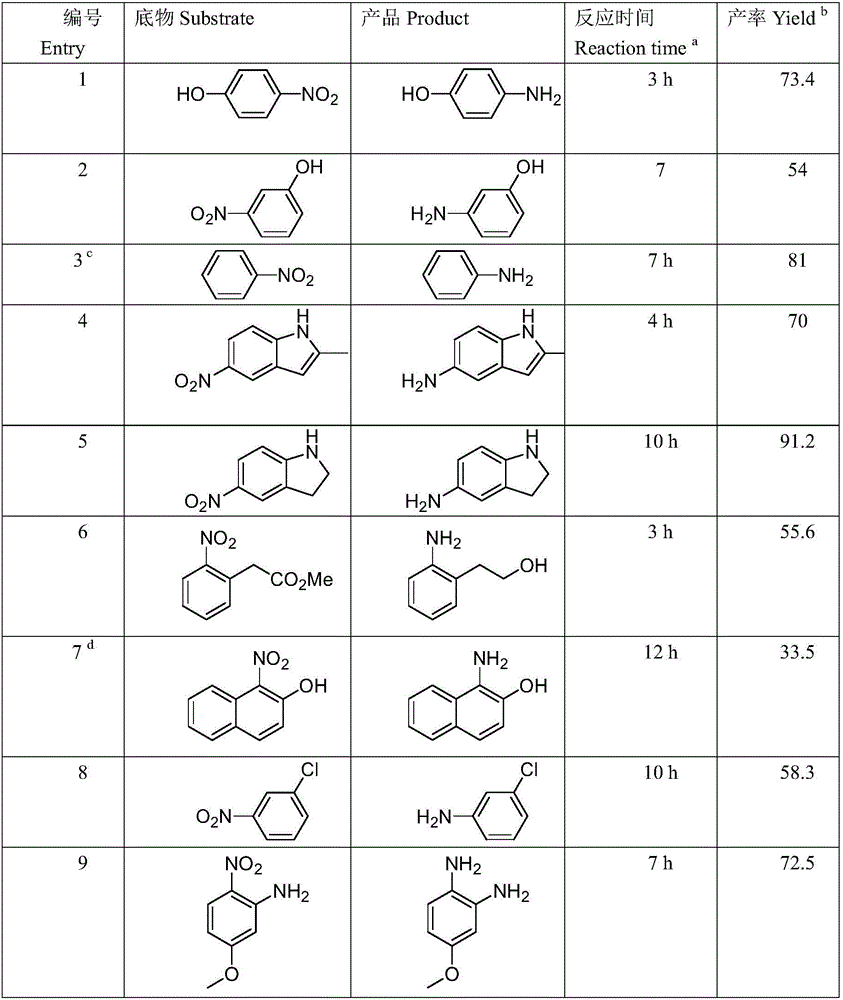

[0016] Example 2: Nano-silver composite textile catalyzes the reduction reaction of nitro compounds

[0017] Using the nano-silver composite textile in Example 1 as a catalyst, we first tried to catalyze the reduction reaction of nitrophenol. Specifically: take 0.2mmol 4-nitrophenol, 1mmolNaBH 4 and 2cm 2 The nano-silver composite textile catalyst was mixed in THF / H at room temperature 2 In O (1ml / 1ml) solution, it can be found by tracking the reaction that 4-nitrophenol can be reduced to 4-aminophenol in 3 hours; at the same time, our negative control test shows that in the absence of adding nano-silver composite textile The catalyst is in the reaction system (other reaction conditions are the same), and no reaction occurs.

[0018] Table 1: Cases of nitro reduction reaction catalyzed by nano-silver composite textile

[0019]

[0020] Reaction conditions: 0.2mmol substrate, 1mmol NaBH 4 and 2cm 2 Nanosilver composite textile catalyst in THF / H 2 O (1ml / 1ml) mixture w...

Embodiment 3

[0022] Example 3: Recycling of nano-silver composite textile catalysts to catalyze the reduction reaction of nitro compounds

[0023] The biggest advantage of nano-silver composite textile catalyst is that it can be recycled. In order to demonstrate its feasibility, we choose 2-methyl-5-nitro-1H-indole as the substrate for research (because of its reduction product and substrate easily separated and purified by chromatography). We take the standard reaction conditions in Example 2 as experimental conditions, we first detect the silver overflow content in the reaction solution after the nano-silver composite textile catalytic reaction finishes by inductively coupled plasma analysis method (ICP-MS), find that only 60ppb Silver appears in the reaction solution, its content is very low.

[0024] On the other hand, under the above reaction conditions, we evaluated the cyclic catalytic times of the nano-silver composite textile catalyst. We controlled the reaction time at 7 hours. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com