Preparation method and application of air purifying material

A technology for purifying air and purifying materials is applied in the field of preparation of metal composite functional materials to achieve the effects of improving purification efficiency, easy large-scale production and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Weigh 6g of potassium permanganate, add it into 100mL of pure water, and sonicate until completely dissolved. Then add 4mL ammonia solution, stir and mix. Degrease and alkali wash the aluminum sheet with a mass of 20g to remove the grease and oxide layer on the surface, wash it with pure water until the surface is completely wet, and then put it into the above-mentioned potassium permanganate-ammonia water mixture. The solution was placed in a constant temperature water bath at 40°C for 5 h. Take out the aluminum sheet and dry it at 60°C to obtain the manganese oxide supported by the aluminum matrix.

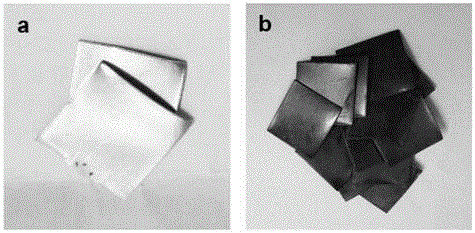

[0032] figure 1 Before and after photos of manganese oxide supported on aluminum flakes. When the aluminum sheet is not loaded ( figure 1 a), showing a silver metal surface; after loading ( figure 1 b), the color of the aluminum sheet is brown, indicating that a large amount of manganese oxide has been loaded on the surface of the aluminum sheet.

[0033] figure 2...

Embodiment 2

[0035] Weigh 0.1g of potassium permanganate, add it into 100mL of pure water, and sonicate until completely dissolved. Then add 1 g of urea, stir and mix. A 0.7g aluminum sheet was degreased and washed with alkali to remove the grease and oxide layer on the surface, washed with pure water until the surface was completely wet, and then put into the above potassium permanganate-urea mixture. The solution was placed in a constant temperature water bath at 95°C for 10 h. Take out the aluminum sheet and dry it at 105°C to obtain the aluminum-based supported manganese oxide.

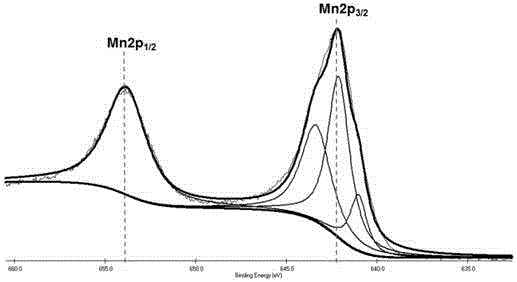

[0036] Figure 4It is the XPS diagram of Mn2p of manganese oxide supported on aluminum base. It can be seen that there are two characteristic peaks at 653.4eV and 641.7eV respectively, and the energy interval of the two peaks is 11.7eV, which are respectively related to the Mn 2p in manganese dioxide. 1 / 2 and Mn2p 3 / 2 It is consistent with the results, so it can be inferred that the manganese oxide suppor...

Embodiment 3

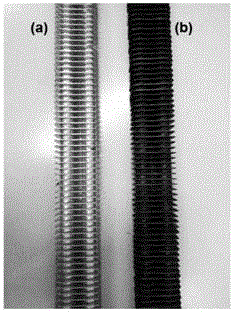

[0039] On the fin of the metal heat exchanger of air conditioner, according to the catalyzer of method load degradation formaldehyde of the present invention (as attached image 3 ). After the formaldehyde catalyst is loaded on the surface of the silver-white metal heat exchanger, the surface of the heat exchanger appears brown. The heat exchanger is fixed on the indoor unit of the air conditioner, and the air conditioner function and air purification function can be realized by controlling the remote control. When the air conditioner is running, start the air purification mode, and the indoor air enters the heat exchanger in the air conditioner shell through the air inlet. After heat exchange, the catalyst on the surface of the heat exchanger degrades the pollutants in the air, and then the clean air Flow out from the air outlet. To achieve air purification. Catalysts working in cooling mode or normal temperature mode can degrade indoor air pollutants; when the air conditi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com