Method for producing optical fiber preform and method for producing optical fiber

An optical fiber preform and a manufacturing method technology, applied in the field of optical fiber manufacturing, can solve problems such as inability to uniformly dope chlorine, inability to fully dehydrate, and characteristic deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach 〕

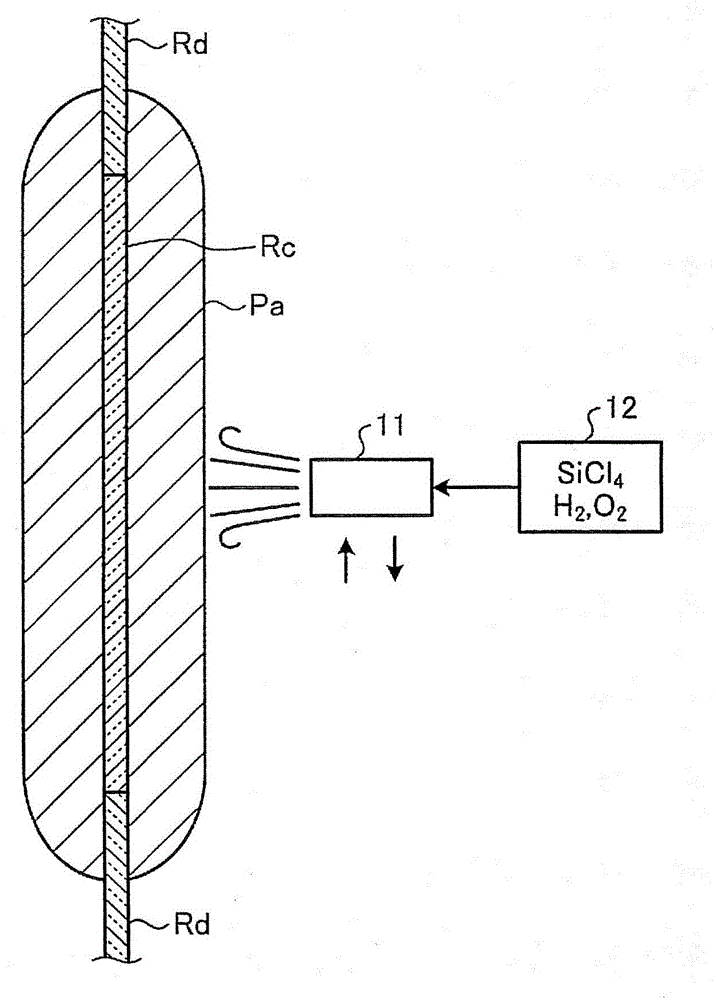

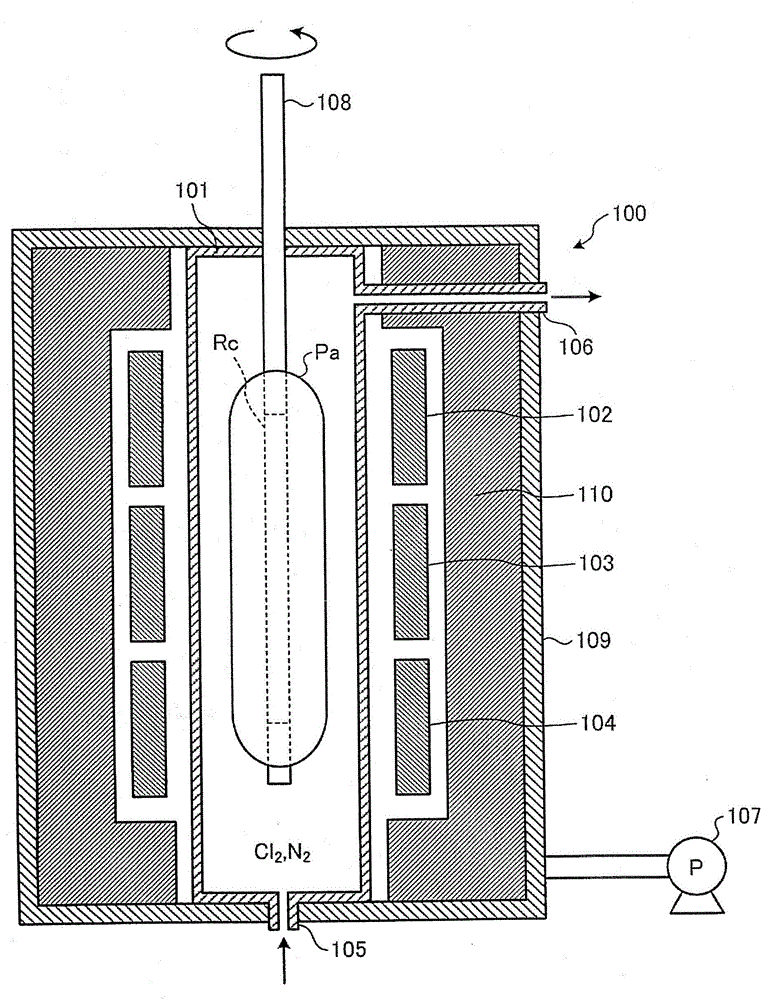

[0028] Here, refer to Figure 1 ~ Figure 4 A method of manufacturing an optical fiber preform and a method of manufacturing an optical fiber according to the first embodiment will be described. figure 1 It is a flowchart showing the procedure of the manufacturing method of the optical fiber preform and the manufacturing method of the optical fiber of the first embodiment. Such as figure 1 As shown, the method for manufacturing an optical fiber preform according to the first embodiment includes a porous preform forming step (step S11), a first dehydration step (step S12), a second dehydration step (step S13), and a sintering step (step S14) . In addition, the optical fiber manufacturing method of the first embodiment further includes a drawing step (step S15 ) after the sintering step (step S14 ) of the optical fiber preform manufacturing method. It should be noted that the method for manufacturing an optical fiber preform and the method for manufacturing an optical fiber ac...

no. 2 approach 〕

[0057] Next, refer to Figure 5 A method of manufacturing an optical fiber preform and a method of manufacturing an optical fiber according to the second embodiment will be described. In addition, in the manufacturing method of the optical fiber preform and the manufacturing method of the optical fiber in 2nd Embodiment, the same apparatus structure as 1st Embodiment is used. Therefore, in the description of the second embodiment, by appropriately referring to Figure 2 ~ Figure 3 The device structure is shown, and the description of the device structure is omitted.

[0058] Figure 5 It is a flowchart showing the procedure of the manufacturing method of the optical fiber preform and the manufacturing method of the optical fiber of the second embodiment. Such as Figure 5 As shown, the method for manufacturing an optical fiber preform according to the second embodiment includes a porous preform forming step (step S21), a first dehydration step (step S22), a second dehydrat...

Embodiment 1

[0078] In the porous preform forming process of Example 1, the core produced by the VAD method was dehydrated and vitrified in a vitrification furnace of a down-draw method generally performed, and then stretched to a predetermined diameter. Mandrel Rc. It should be noted that the cladding diameter / core diameter of the core rod Rc is 4.2, and the packing density around the core rod Rc is 0.7 g / cm by OVD method. 3 The porous layer, thus making the porous preform Pa.

[0079] In the first dehydration process, the second dehydration process and the semi-sintering process, use image 3 Using a vitrification furnace 100 as shown, the porous preform Pa is semi-sintered into an optical fiber preform Pb in a "translucent glass state". At this time, the treatment temperature and treatment time of the first dehydration step were 1000°C×3 hours, and the treatment temperature and treatment time of the second dehydration step were 1200°C×2 hours. In addition, the ambient gas in the furn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com