Method for regenerating working solution used for production of hydrogen peroxide and method for producing hydrogen peroxide using regenerated working solution

A working solution, hydrogen peroxide technology, applied in the direction of peroxide/peroxyhydrate/peroxyacid/superoxide/ozonide, metal/metal oxide/metal hydroxide catalyst, organic chemistry method, etc. , which can solve the problems of reducing the production efficiency of hydrogen peroxide, and achieve the effect of reducing the amount of solvent used, reducing the risk, and realizing the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

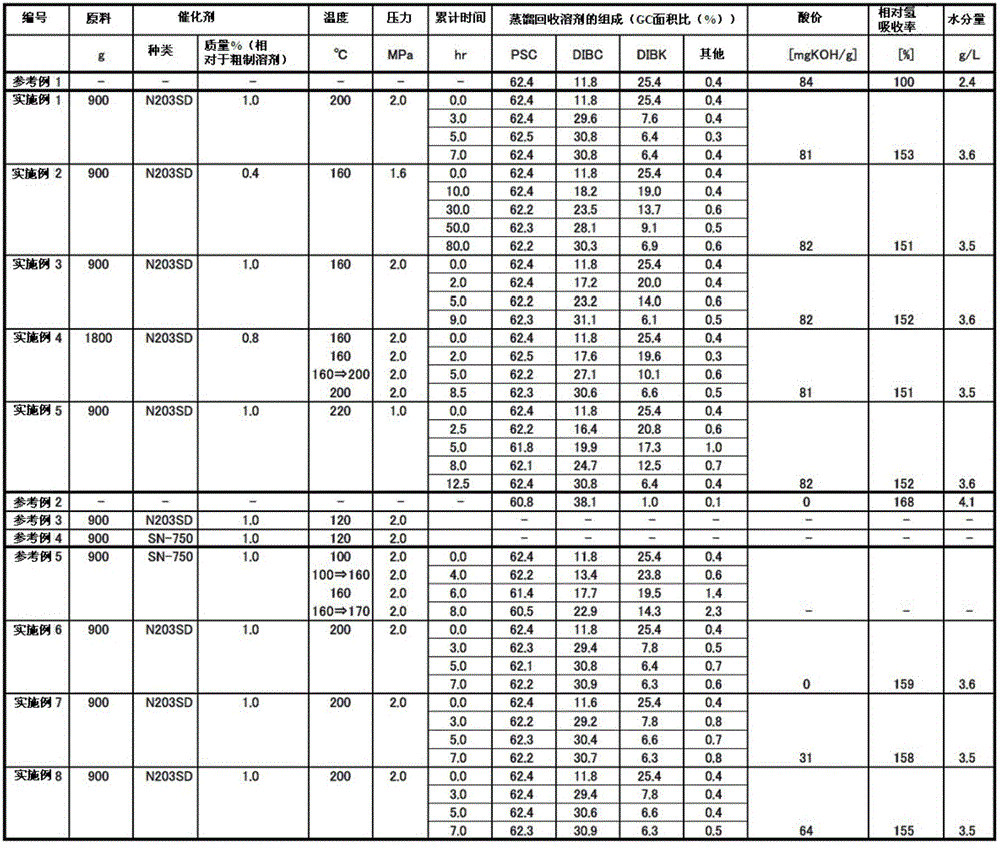

[0058] Hereinafter, the present invention will be described in more detail by way of examples, but the present invention is not limited to these examples. Among them, in the present invention, pseudocumene (PSC) is used as the aromatic hydrocarbon as the nonpolar solvent in the working solution, and diisobutylcarbinol (DIBC) is used as the higher alcohol as the polar solvent. The ketone body derived from diisobutyl carbinol is diisobutyl ketone (DIBK), and each organic solvent component was measured by gas chromatography (GC). Among the organic solvent components, dimethylbenzoic acid, alkylphthalic anhydride, aliphatic carboxylic acids, trimethylphenol and 2 , 6-Dimethyl-4-heptanediol, etc.

[0059]

[0060] The acid value measurement of a solvent was performed based on JIS-K0070. The details are as follows. First, 40 mL of a solvent sample and 20 mL of an N / 10 sodium carbonate aqueous solution were weighed in a flask, and extracted at 50° C. for 15 minutes. Leave the e...

reference example 1

[0068]

[0069] As the working solution used in the first distillation step of the present invention, a working solution that has been used for many years in an actual hydrogen peroxide production device is used. Take out 2000ml of working solution from the hydrogen peroxide production device. The reaction medium in the working solution is amyl anthraquinone and amyl tetrahydroanthraquinone. In the recovery of the organic solvent component in the first stage, 400 ml of the working solution was placed in advance in a 1000 ml flask equipped with a distillation device, the degree of vacuum was controlled to 13 kPa, and the temperature was raised from room temperature. Distillation began when the temperature of the kettle reached 130°C. Since the liquid volume in the flask gradually decreased, the remaining working solution was gradually added, and the addition was stopped when the total amount added reached 2000ml. After the addition of the working solution was stopped, the di...

Embodiment 1

[0077]

[0078] 900 g of the solvent recovered by distillation and 9 g of N203SD (Cu-Cr based catalyst) manufactured by Nikki Kasei Co., Ltd. as a catalyst (1% by mass relative to the solvent recovered by distillation) were added to the autoclave, and a hydrogenation reaction was performed for 7 hours. The reaction temperature is controlled at 200° C., and the reaction pressure is controlled at 2.0 MPa. After completion of the hydrogenation reaction, the catalyst was left to stand at room temperature, and then, the catalyst was separated by filtration with a filter No. 1 made by ADVANTEC. The solvent obtained by performing hydrogenation reaction on the recovered solvent by distillation is called a hydrogenated solvent. As a result of analyzing this hydrogenation solvent component by GC, pseudocumene / diisobutylmethanol / diisobutyl ketone=62.4 mass % / 30.8 mass % / 6.4 mass %. Table 1 shows the GC analysis results of the hydrogenation solvent components accompanying the passage o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorptance | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com