Dynamic reliable control strategy of high-capacity contactor

A control strategy and contactor technology, applied in relays, electrical components, circuits, etc., can solve the problems of reducing the mechanical life of contactors, aggravating the breaking process, and limiting applications, so as to reduce impact, reduce contact bounce, and reduce ablation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

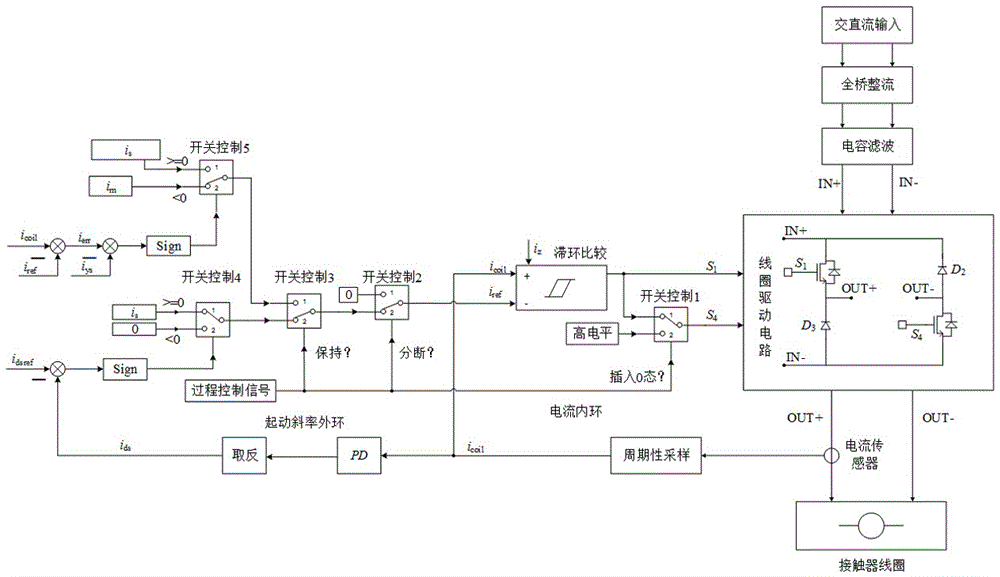

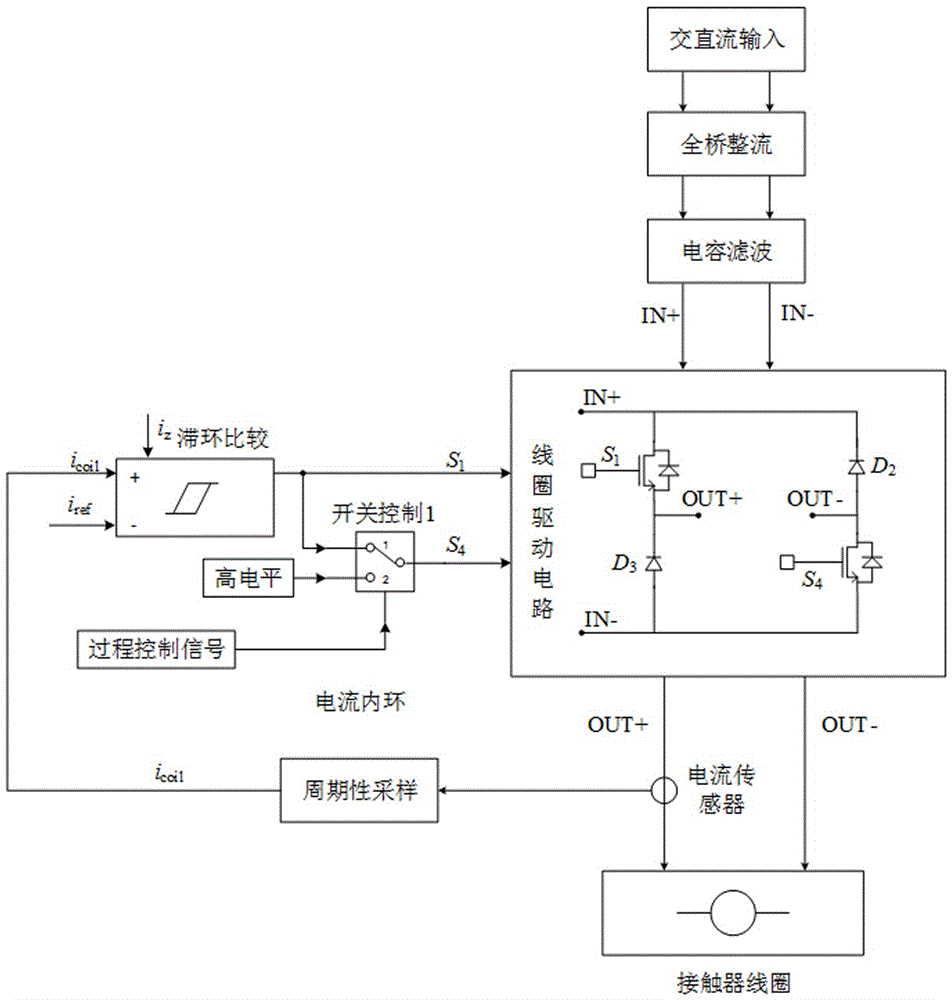

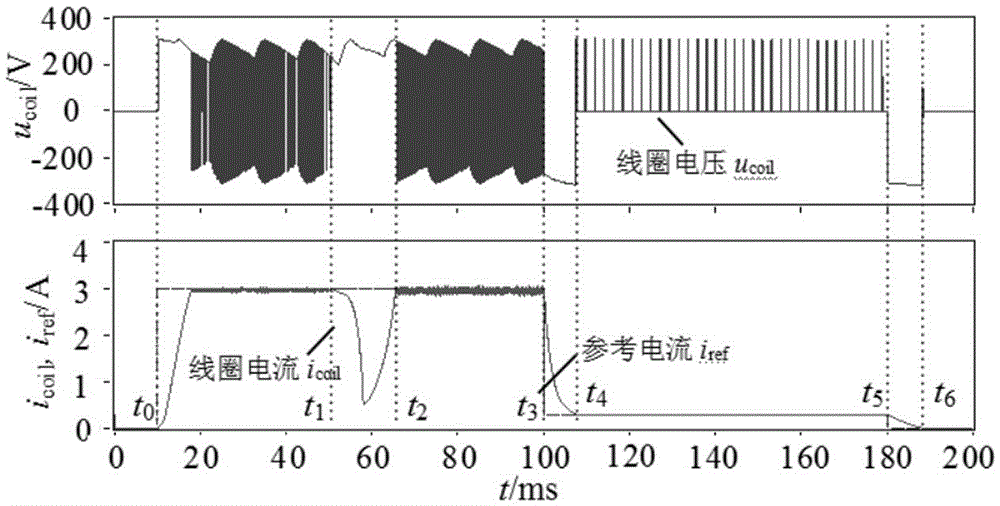

[0029] Please refer to figure 1 , the principle of the dynamic and reliable control strategy of the large-capacity contactor provided by the present invention is as follows figure 1 As shown, the hardware circuit principle it relies on is: the AC-DC input power is rectified and filtered by the full bridge to become a DC voltage with less pulsation, and then it is applied to both ends of the coil of the contactor through the chopping control of the coil drive circuit; The chopper control circuit consists of a power electronic switch S 1 , S 4 and fast recovery diode D 2 、D 3 According to the polarity of the voltage applied to both ends of the coil, three circuit states are defined: when S 1 , S 4 At the same time, it is turned on, and the forward voltage is applied to both ends of the coil, which can make the coil current rise rapidly. At this time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com