Dryer for broadleaf holly leaves

The technology of a Kuding tea dryer and a hot air blower is applied in the directions of dryer, drying, tea drying, etc., which can solve the problems of opening of tea rolls and affecting the shape of tea leaves, and achieves high integrity, simple structure, and avoidance of the effect of destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below through specific implementations:

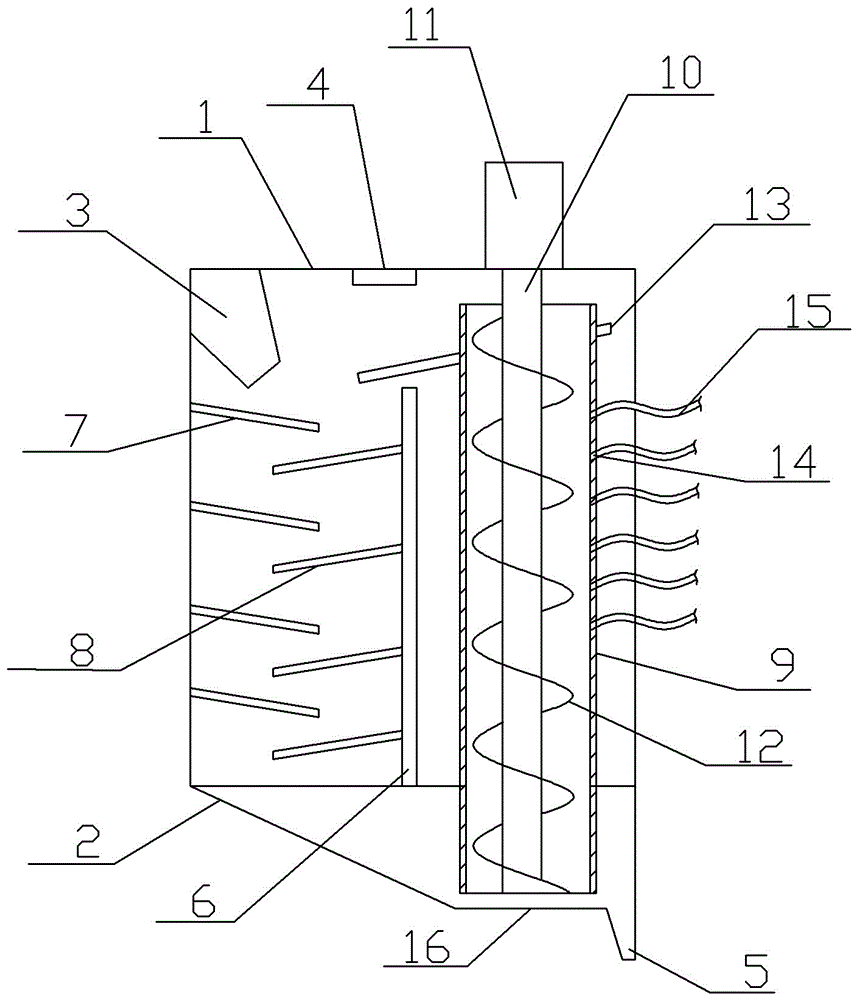

[0014] The reference signs in the drawings of the specification include: shell 1, cone 2, feed hopper 3, main hot air inlet 4, discharge port 5, partition 6, first folded plate 7, second folded plate 8, Cylinder 9, rotating shaft 10, rotating electric machine 11, spiral blade 12, guide plate 13, hot air hole 14, hose 15, buffer surface 16.

[0015] Example Kudingcha dryer is basically as attached figure 1 Shown: It includes a rectangular housing 1 with a cover fixed on the top of the housing 1. A feed hopper 3 is opened on the left side of the upper end of the shell 1, and a cone 2 is fixed at the lower end of the shell 1, and the cone 2 is welded and communicated with the shell 1. The left side of the cone 2 is a conical surface, the right side is a vertical surface, and the lower end of the cone 2 is provided with a discharge port 5.

[0016] The inner wall of the shell 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com