Method for magnetic separation of low-grade chromium-containing vanadium-titanium magnetite metallized pellets

A technology of vanadium-titanium magnetite and metallized pellets, which is applied in the fields of magnetic separation, chemical instruments and methods, and solid separation, can solve the problems of lack of research on low-grade chromium-containing vanadium-titanium magnetite, and meet the needs of production On-site requirements, beneficial to separation, and the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

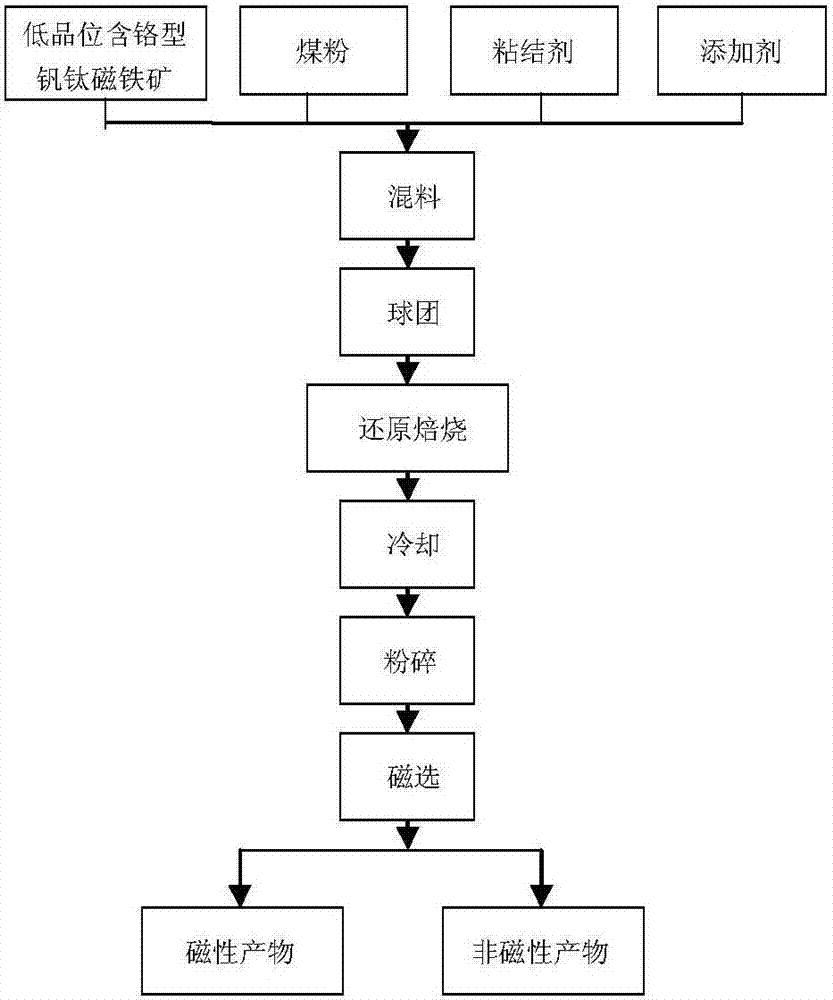

[0055] A method for magnetic separation of low-grade chromium-containing type vanadium-titanium magnetite metallized pellets is carried out according to the following steps:

[0056] Step 1, mixing ingredients:

[0057] Weigh low-grade chromium-containing vanadium-titanium magnetite powder, reduced coal powder, and bentonite and put them into a ball mill for mixing. The mixing time is 4 hours to obtain a mixed material; wherein, the carbon in the reduced coal powder and the low-grade Oxygen of iron oxide in the chromium-containing type vanadium-titanium magnetite powder, by carbon-oxygen ratio (C / O)=1.2, namely by mass ratio, low-grade chromium-containing type vanadium-titanium magnetite powder: reduced coal powder=4.27, The bentonite content is 2% of the mass of the mixed material;

[0058] Step 2, making balls:

[0059] (1) Add water to the mixed material, mix, and stew the material for 40 minutes; wherein, according to the mass ratio, the amount of water added to the mixe...

Embodiment 2

[0070] A method for magnetic separation of low-grade chromium-containing type vanadium-titanium magnetite metallized pellets is carried out according to the following steps:

[0071] Step 1, mixing ingredients:

[0072] Weigh low-grade chromium-containing vanadium-titanium magnetite powder, reduced coal powder, and bentonite and put them into a ball mill for mixing. The mixing time is 5 hours to obtain a mixed material; wherein, the carbon in the reduced coal powder and the low-grade Oxygen of iron oxide in the chromium-containing type vanadium-titanium magnetite powder, by carbon-oxygen ratio (C / O)=1.1, namely by mass ratio, low-grade chromium-containing type vanadium-titanium magnetite powder: reducing coal powder=4.66, The bentonite content is 1.5% of the mass of the mixed material;

[0073] Step 2, making balls:

[0074] (1) Add water to the mixed material, mix, and stew the material for 30 minutes; wherein, according to the mass ratio, the amount of water added to the m...

Embodiment 3

[0085] A method for magnetic separation of low-grade chromium-containing type vanadium-titanium magnetite metallized pellets is carried out according to the following steps:

[0086] Step 1, mixing ingredients:

[0087] Weigh low-grade chromium-containing vanadium-titanium magnetite powder, reduced coal powder, bentonite and CaF 2 Put it into a ball mill, mix the materials, and the mixing time is 5h to obtain the mixed material; wherein, the carbon in the reduced coal powder and the oxygen of the iron oxide in the low-grade chromium-containing type vanadium-titanium magnetite powder are calculated according to the carbon-oxygen ratio (C / O)=1.2, that is, by mass ratio, low-grade chromium-containing type vanadium-titanium magnetite powder: reduced coal powder=4.27, bentonite content is 2% of the mixed material quality, CaF 2 The content is 8% of the total mixed material;

[0088] Step 2, making balls:

[0089] (1) Add water to the mixed material, mix, and stew the material fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com