Magnetic separation method for low-grade chromium-containing vanadium titanium magnetite metalized pellet

A technology of metallized pellets and vanadium-titanium magnetite, applied in magnetic separation, chemical instruments and methods, solid separation, etc., can solve the problems of lack of research on low-grade chromium-containing vanadium-titanium magnetite, etc., and meet the requirements of production On-site requirements, simple operation, beneficial to the effect of iron recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

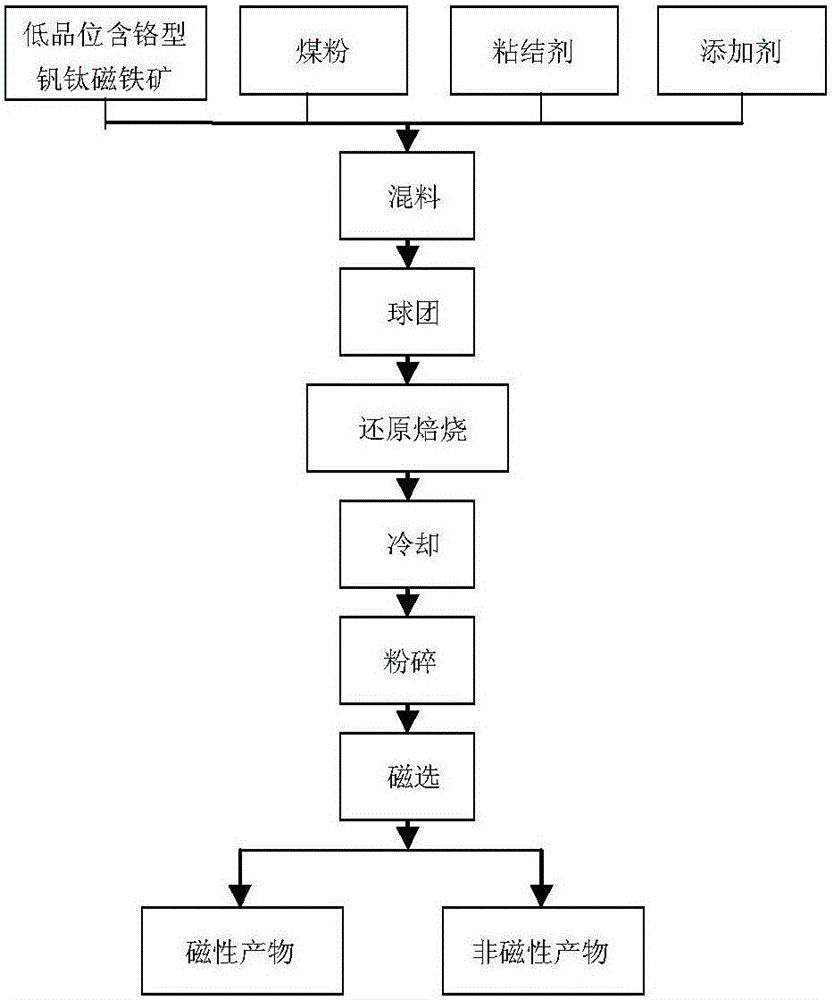

[0055] A method for magnetic separation of low-grade chromium-containing type vanadium-titanium magnetite metallized pellets is carried out according to the following steps:

[0056] Step 1, mixing ingredients:

[0057] Weigh low-grade chromium-containing vanadium-titanium magnetite powder, reduced coal powder, and bentonite and put them into a ball mill for mixing. The mixing time is 4 hours to obtain a mixed material; wherein, the carbon in the reduced coal powder and the low-grade Oxygen of iron oxide in the chromium-containing type vanadium-titanium magnetite powder, by carbon-oxygen ratio (C / O)=1.2, namely by mass ratio, low-grade chromium-containing type vanadium-titanium magnetite powder: reduced coal powder=4.27, The bentonite content is 2% of the mass of the mixed material;

[0058] Step 2, making balls:

[0059] (1) Add water to the mixed material, mix, and stew the material for 40 minutes; wherein, according to the mass ratio, the amount of water added to the mixe...

Embodiment 2

[0070] A method for magnetic separation of low-grade chromium-containing type vanadium-titanium magnetite metallized pellets is carried out according to the following steps:

[0071] Step 1, mixing ingredients:

[0072] Weigh low-grade chromium-containing vanadium-titanium magnetite powder, reduced coal powder, and bentonite and put them into a ball mill for mixing. The mixing time is 5 hours to obtain a mixed material; wherein, the carbon in the reduced coal powder and the low-grade Oxygen of iron oxide in the chromium-containing type vanadium-titanium magnetite powder, by carbon-oxygen ratio (C / O)=1.1, namely by mass ratio, low-grade chromium-containing type vanadium-titanium magnetite powder: reducing coal powder=4.66, The bentonite content is 1.5% of the mass of the mixed material;

[0073] Step 2, making balls:

[0074] (1) Add water to the mixed material, mix, and stew the material for 30 minutes; wherein, according to the mass ratio, the amount of water added to the m...

Embodiment 3

[0085] A method for magnetic separation of low-grade chromium-containing type vanadium-titanium magnetite metallized pellets is carried out according to the following steps:

[0086] Step 1, mixing ingredients:

[0087] Weigh low-grade chromium-containing vanadium-titanium magnetite powder, reduced coal powder, bentonite and CaF 2 Put it into a ball mill, mix the materials, and the mixing time is 5h to obtain the mixed material; wherein, the carbon in the reduced coal powder and the oxygen of the iron oxide in the low-grade chromium-containing type vanadium-titanium magnetite powder are calculated according to the carbon-oxygen ratio (C / O)=1.2, that is, by mass ratio, low-grade chromium-containing type vanadium-titanium magnetite powder: reduced coal powder=4.27, bentonite content is 2% of the mixed material quality, CaF 2 The content is 8% of the total mixed material;

[0088] Step 2, making balls:

[0089] (1) Add water to the mixed material, mix, and stew the material fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com