A kind of natural fruit and vegetable cleaning powder and preparation method thereof

A fruit and vegetable cleaning, natural technology, applied in the direction of chemical instruments and methods, detergent compositions, non-surface active detergent compositions, etc., can solve the problems of low application value, achieve less heavy metal pollution, excellent effect, and safe raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

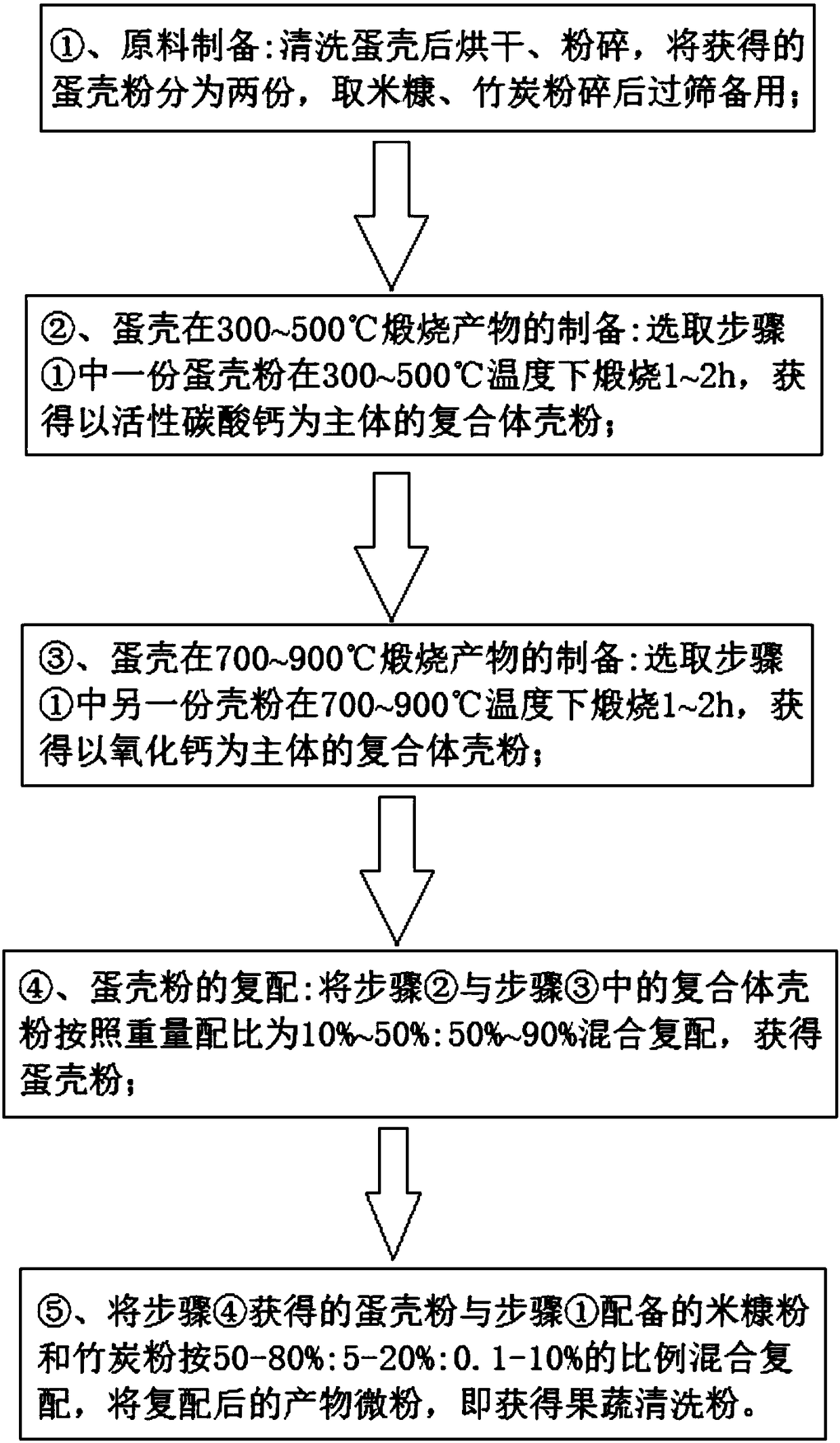

[0032] The preparation method of a kind of natural fruit and vegetable cleaning powder of the present invention, its principle is: the calcined eggshell powder, rice bran powder, bamboo charcoal powder are mixed and compounded, and the characteristic of above-mentioned three kinds of materials is brought into full play, namely calcined eggshell powder decomposes pesticide, rice bran powder Adsorbing pesticides and heavy metals, bamboo charcoal has the characteristics of adsorbing organophosphorus pesticides and heavy metal complexes, so as to achieve the purpose of safely, efficiently and quickly removing pesticide residues, pathogenic bacteria and heavy metals on the surface of fruits and vegetables.

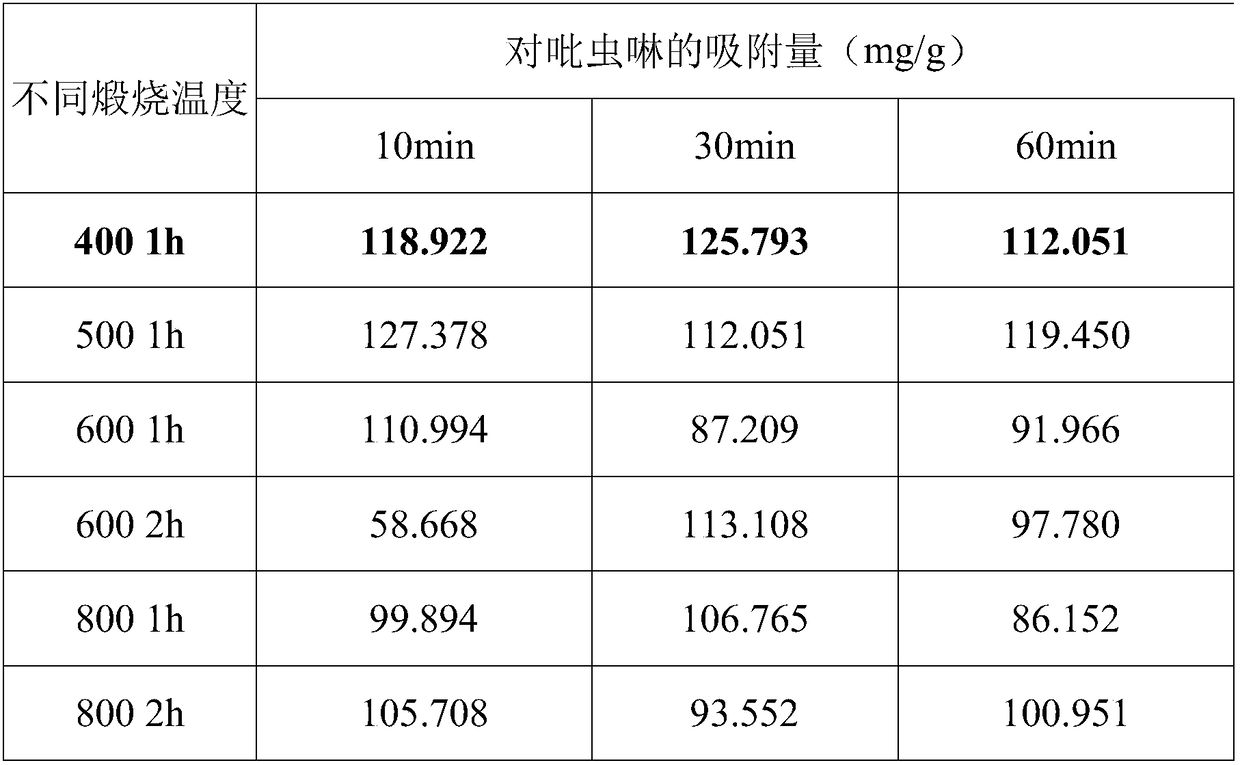

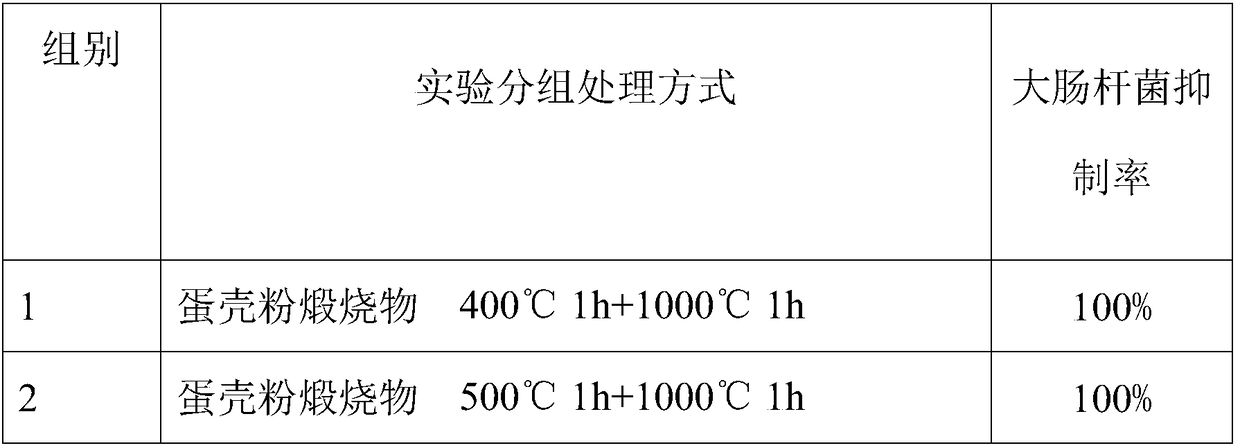

[0033] 1. Determination of eggshell calcination temperature

[0034] Eggshell is a natural biomineralized material rich in calcium carbonate (over 95%). Eggshells have a loose and porous structure. Previous studies have shown that eggshells have certain adsorption properties fo...

Embodiment 1

[0070] Collect the discarded eggshells, wash them with tap water, and then send them to an oven for drying at a constant temperature of 110°C, so that the inner and outer surfaces of the eggshells are dry, crush them into shell powder, and send them to the ashing furnace in batches. Calcined at 400°C for 60 minutes, fixed temperature at 800°C / calcined for 60 minutes, eggshell ash powder with different whiteness can be obtained after calcined, and the products of the two calcined processes are compounded at a ratio of 4:6, and then the The ratio of eggshell powder: rice bran powder: bamboo charcoal powder is 80%: 10%: 10%, after mixing evenly, micro-nano crushing is made into fruit and vegetable cleaning powder products.

[0071] Take 1g of fruit and vegetable cleaning powder, add 1L of water, and prepare a solution. Soak 300g of grapes in the solution for 20 minutes, take it out and rinse with water. Take 2g of grape skins and use the pesticide residue detection kit to detect...

Embodiment 2

[0073] Collect the discarded eggshells, wash them with tap water, and then send them to an oven for drying at a constant temperature of 110°C, so that the inner and outer surfaces of the eggshells are dry, crush them into shell powder, and send them to the ashing furnace in batches. Calcined at 500°C for 60 minutes, fixed temperature at 900°C / calcined for 60 minutes, eggshell ash powder with different whiteness can be obtained after calcined, the products of the two calcined processes are compounded at a ratio of 3:7, and the Eggshell powder: rice bran powder: bamboo charcoal powder is 75%: 20%: 5% after mixing evenly, micro-nano crushing to make fruit and vegetable cleaning powder products.

[0074] Take 0.6g of fruit and vegetable cleaning powder, add 1L of water, and prepare a solution. Soak 2 apples in the solution for 30 minutes, take them out and rinse them with clean water. Take 5g of apple peel, and use the pesticide residue detection kit to detect the pesticide resid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com