Grease refining method based on enzymatic degumming technology

A degumming and oil technology, applied in the direction of fat oil/fat refining, fat production, etc., can solve the problems affecting the application value of acidified oil and the inability of phospholipids to be used, and achieve the effect of convenient high-value utilization, reducing phospholipid content and improving quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 (contrast)

[0035] Hydrated degummed soybean oil crude oil 5kg (provided by Guangzhou Zhizhiyuan Oil Industry Co., Ltd., phosphorus content is 176.2mg / kg, acid value 2.3), heated to 80°C, then added 10mL of 45% citric acid aqueous solution, mixed homogeneously Mix well, then stir for 30 minutes, add 100 mL of 15% NaOH solution, stir and mix for 1 minute, centrifuge to remove soapstock, and then wash with water to obtain desoaped oil, which is recorded as desoaped oil 1. The phosphorus content of desoaped oil 1 was measured to be 8.3 mg / kg.

[0036] Take 500g of desoaped oil, after vacuum drying, add 1% activated clay for decolorization, and then put it in a flask for deodorization. Then you can get refined oil.

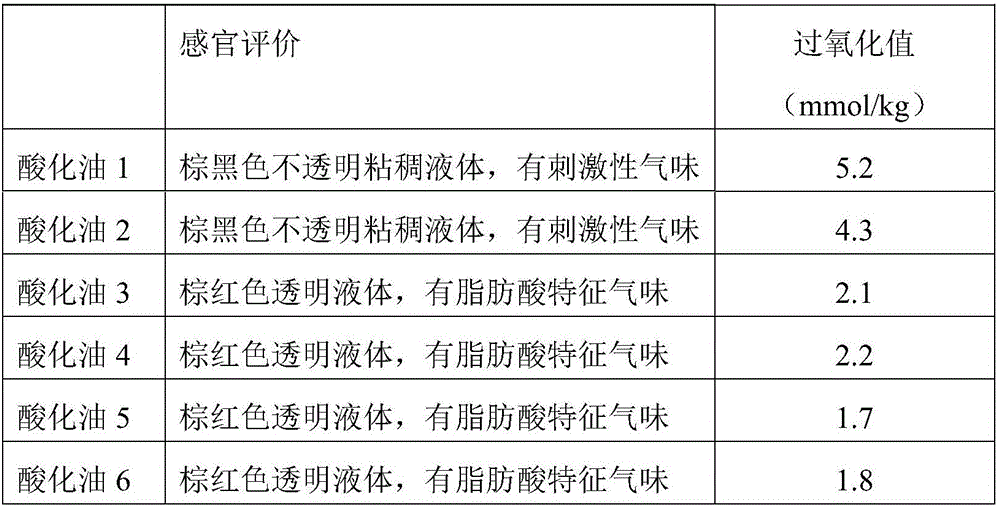

[0037] Take 100g of soapstock, add excess dilute sulfuric acid to acidify, stir for 5 minutes, observe that the oil layer is not complete, then heat it to reflux for 4 hours, leave it to stand and layer well, and obtain acidified oil, which is r...

Embodiment 2

[0038] Embodiment 2 (contrast)

[0039] Soybean oil crude crude oil 5kg (provided by Guangzhou Zhizhiyuan Oil Industry Co., Ltd., phosphorus content is 962.3mg / kg, acid value 2.1), heated to 80°C, then added 10mL of 45% citric acid aqueous solution, homogeneously mixed Then stir and react for 30 minutes, add 100 mL of 15% NaOH solution, stir and mix for 1 minute, centrifuge to remove soapstock, and then wash with water to obtain desoaped oil, which is recorded as desoaped oil 2. The phosphorus content of desoaped oil 2 was measured to be 11.2 mg / kg.

[0040] Take 500g of desoaped oil, after vacuum drying, add 1% activated clay for decolorization, and then put it in a flask for deodorization. Then you can get refined oil.

[0041] Take 100g of soapstock, add excess dilute sulfuric acid to acidify, stir for 5 minutes, observe that the grease layer is not complete, then heat it to reflux for 4 hours, leave it to stand and layer well, and get acidified oil, which is recorded as ...

Embodiment 3

[0043] Hydrated degummed soybean oil crude oil 5kg (provided by Guangzhou Zhizhiyuan Oil Industry Co., Ltd., phosphorus content is 176.2mg / kg, acid value 2.3), heated to 80°C, then added 10mL of 45% citric acid aqueous solution, mixed homogeneously Mix evenly, then stir for 30 minutes, cool down to 53°C, add 110 mL of 4% NaOH solution, mix well, then add 0.05 g of phospholipase Lecitase Ultra (provided by Novozymes, the measured activity is 10260 U / mL), and mix homogeneously for 5 minutes after adding the enzyme , and then stirred and reacted for 2 hours and then left to stand for stratification. The lower layer is colloid, and the upper layer is enzymatic degummed oil. The measured phosphorus content is 16.2mg / kg.

[0044] Add 80 mL of 15% NaOH solution to the enzymatically degummed oil, stir and mix for 1 min, centrifuge to remove soapstock, and then wash with water to obtain desoaped oil, which is recorded as desoaped oil 3. The phosphorus content of desoaped oil 3 was meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com