Dual-cured matte paint system

A double-curing, matte technology, applied in the direction of polyester coatings, polyether coatings, polyurea/polyurethane coatings, etc., can solve the problems of long drying time, high difficulty of finishing, and unnatural appearance of the paint film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

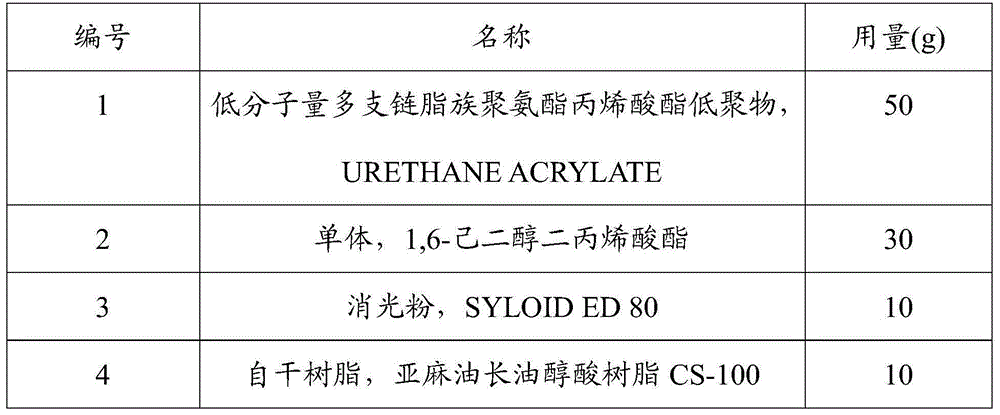

[0057] Embodiment 1: the preparation of coating composition-1

[0058] In this example, PPG Oak Creek's URETHANE ACRYLATE, a low molecular weight highly branched aliphatic urethane acrylate oligomer, was used as the oligomer; and 1,6-hexanediol diacrylate was used as the monomer .

[0059] Components 1 and 2 were mixed together at room temperature in the amounts indicated in the table below, and the mixture was stirred homogeneously using a EUROSTAR mixer from IKA-WERKE at 800 rpm. Slowly add matting powder at 500rpm, then disperse the mixture at 1500rpm for 20 minutes until the fineness reaches 40 microns. Subsequently, long oil alkyd resin (CS-100 of Guolong) was added, and the mixture was stirred uniformly at a rotation speed of 800 rpm, thereby obtaining coating composition-1 according to the present invention, which was a full matte coating.

[0060] Table 1: Components and contents of coating composition-1

[0061]

Embodiment 2

[0062] Embodiment 2: the preparation of coating composition-2

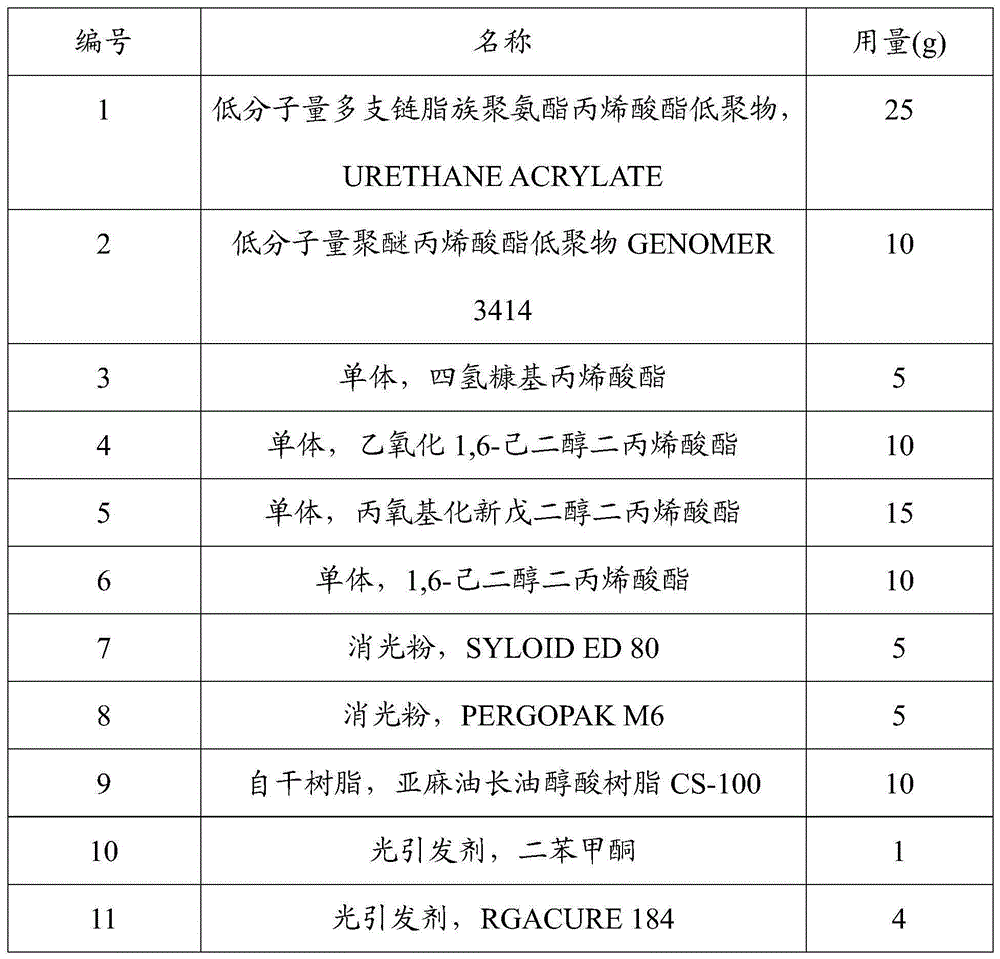

[0063] In this example, PPG Oak Creek's URETHANE ACRYLATE (a low molecular weight highly branched aliphatic urethane acrylate oligomer) and RAHN's GENOMER3414 (a low molecular weight polyether acrylate oligomer) were used as oligomers. and use a mixture of propoxylated neopentyl glycol diacrylate, tetrahydrofurfuryl acrylate, 1,6-hexanediol diacrylate, ethoxylated 1,6-hexanediol diacrylate as mono body.

[0064]Components 1 to 6 in the amounts shown in the table below were mixed together at room temperature, and the mixture was stirred uniformly at 800 rpm using a EUROSTAR mixer from IKA-WERKE. Slowly add matting powder at 500rpm, and disperse the mixture at 1500rpm at high speed for 15-30 minutes until the fineness reaches 35 microns. Subsequently, long oil alkyd resin (CS-100 of Guolong) was added, and the mixture was stirred evenly at a rotation speed of 800 rpm, thereby obtaining coating composition-2 accord...

Embodiment 3

[0067] Embodiment 3: the preparation of coating composition-3

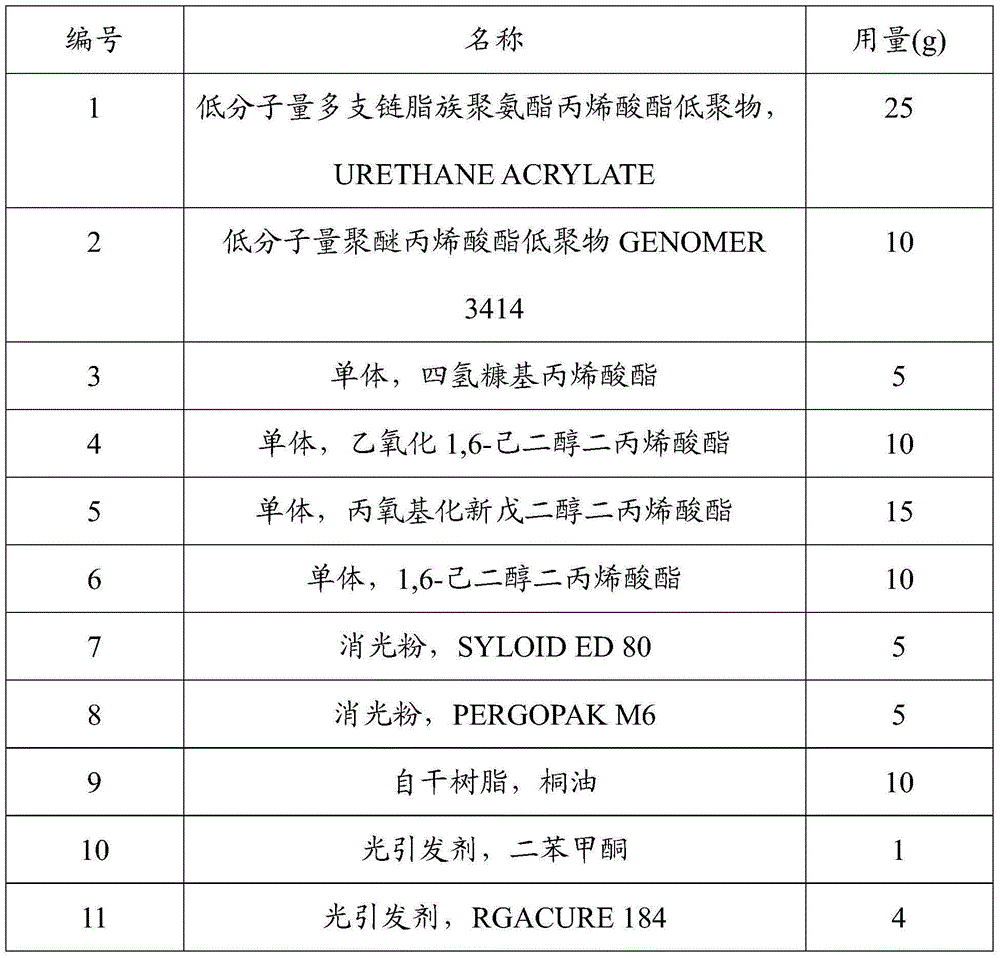

[0068] In this example, PPG Oak Creek's URETHANE ACRYLATE and RAHN's GENOMER 3414 were used as oligomers; and propoxylated neopentyl glycol diacrylate, tetrahydrofurfuryl acrylate, 1,6-hexanedi A mixture of alcohol diacrylate and ethoxylated 1,6-hexanediol diacrylate as monomer.

[0069] Components 1 to 6 in the amounts shown in the table below were mixed together at room temperature, and the mixture was stirred uniformly at 800 rpm using a EUROSTAR mixer from IKA-WERKE. Add matting powder slowly at 500rpm, and disperse the mixture at high speed at 1500rpm for 15-30 minutes until the fineness reaches 30 microns. Then tung oil was added, and the mixture was stirred evenly at a speed of 800 rpm to obtain coating composition-3 according to the present invention, which was a full-matte coating composition.

[0070] Table 3: Composition and dosage of coating composition-3

[0071]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com