Zirconium diboride-based composite material toughened by colloid-dispersed chopped carbon fibers and preparation method thereof

A chopped carbon fiber and colloidal dispersion technology, applied in the field of ultra-high temperature ceramic matrix composite materials, can solve the toughening mechanism such as unfavorable fiber pullout, increase the reactivity of fiber and matrix, and limit the toughening effect of chopped carbon fiber. The effect of promoting the densification process, increasing the strength, and reducing the grain growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

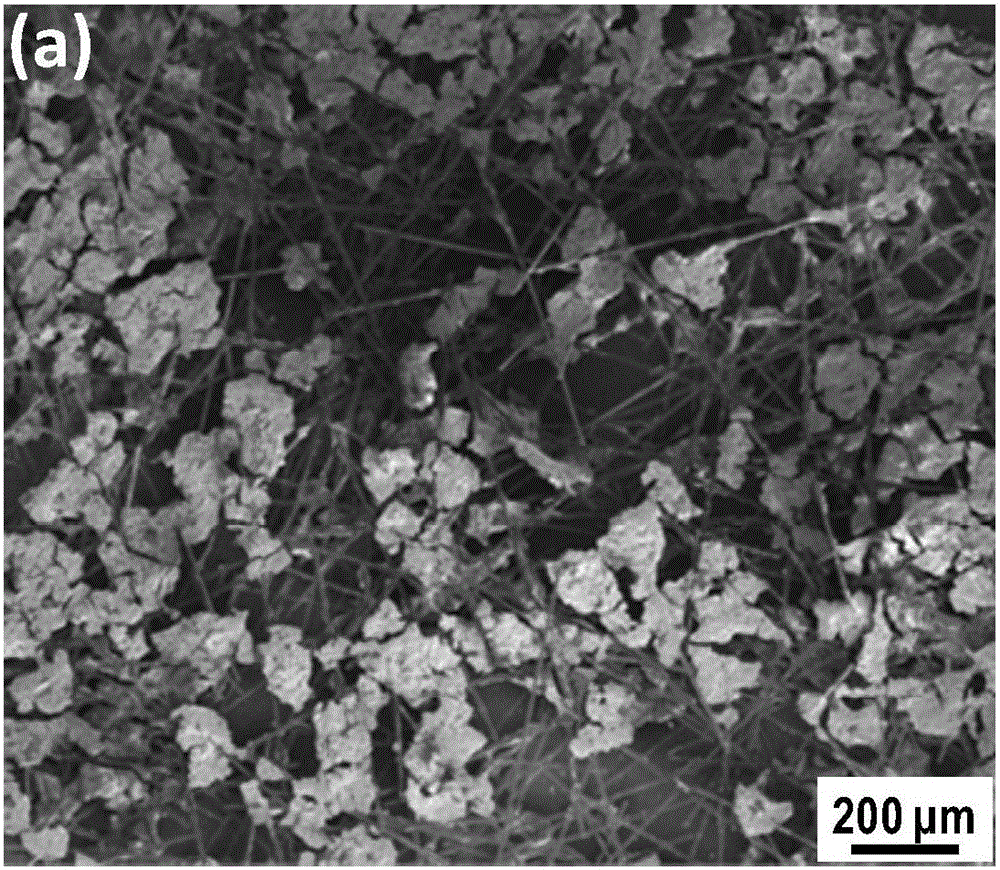

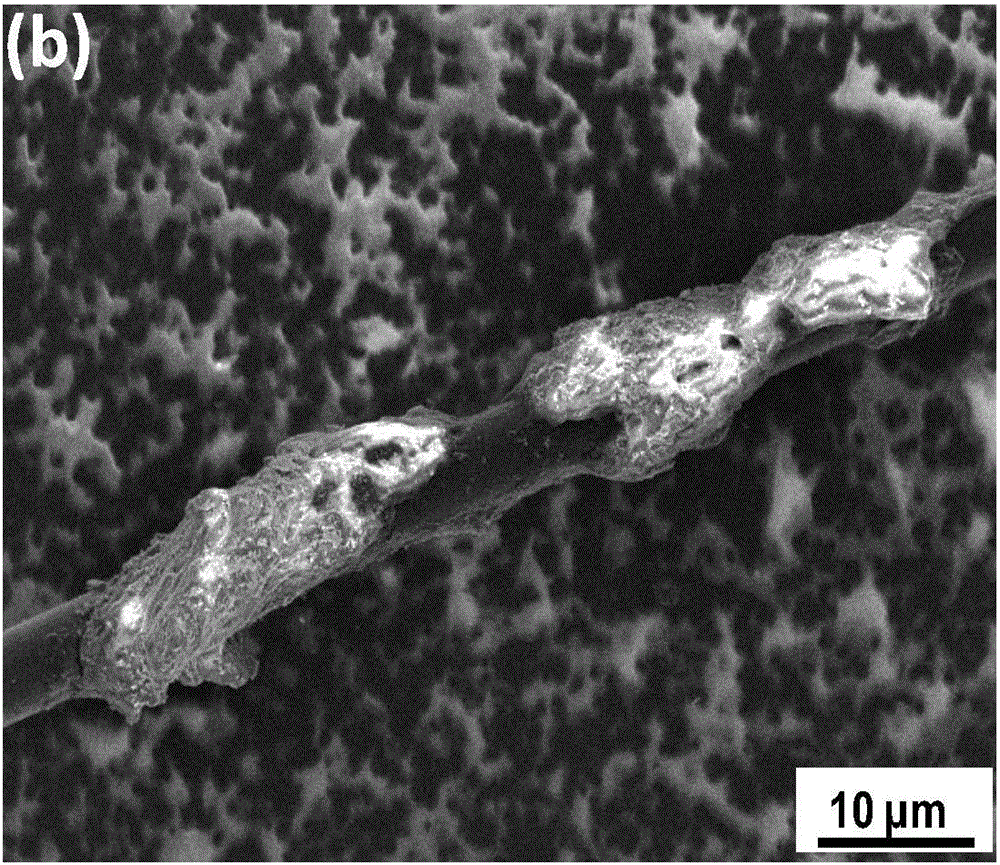

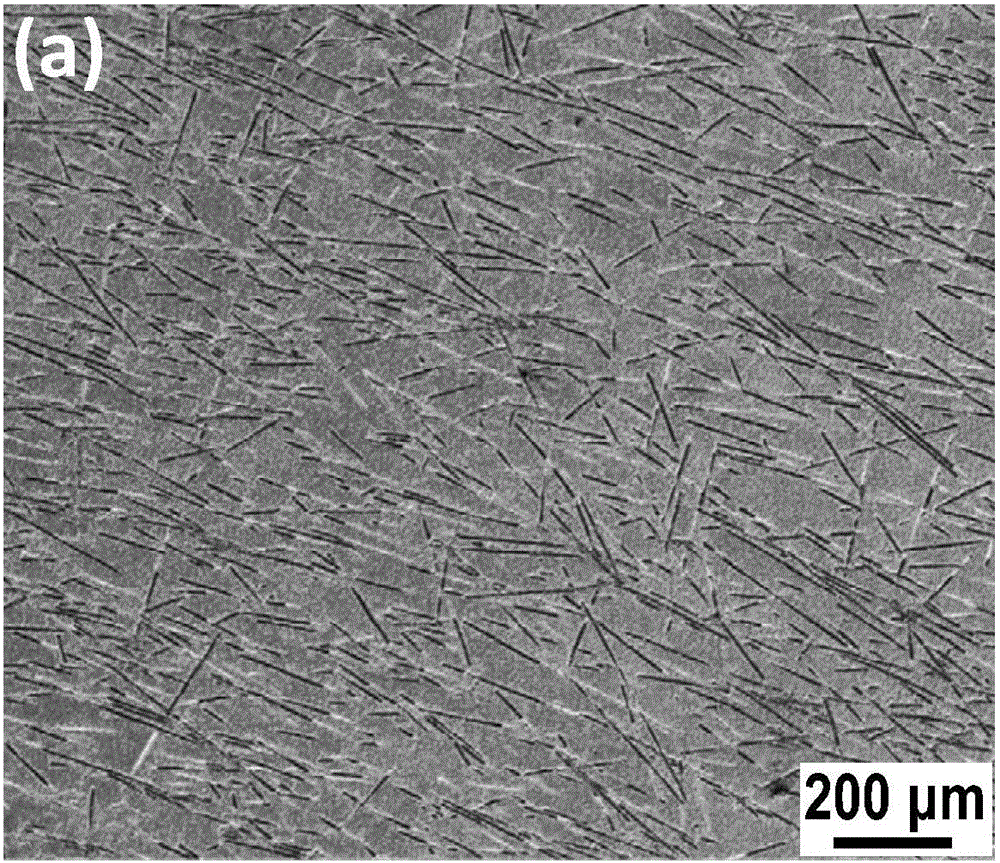

[0033] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

[0034] A colloid-dispersed chopped carbon fiber toughened zirconium diboride-based composite material and a preparation method thereof, which are made of the following raw materials in parts by weight (g): chopped carbon fiber 2 (average length 2mm), nanometer zirconium diboride Powder 20, nano-silicon carbide powder 2, phenolic resin 3, polyethyleneimine 0.3, absolute ethanol 80.

[0035] The method for colloid dispersing chopped carbon fibers is as follows: dissolving phenolic resin with a mass fraction of 3 in absolute ethanol with a mass fraction of 80; adding chopped carbon fibers with a mass fraction of 2; and then adding mass fractions 2 nano-silicon carbide powder, and disperse by ultrasonic vibration for 2 hours; slowly add polyethyleneimine with a mass fraction of 0.3, and stir for 2 hours; vacuumize the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com