Glass fiber mat-reinforced silica aerogel and preparation method thereof

A technology of glass fiber mat and silica, which is applied in the field of airgel materials and its preparation, can solve the problems of difficult fixation of the reinforced phase structure, long production cycle, poor toughness, etc., and achieve good hydrophobicity, optimized composition, and improved toughness and the effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

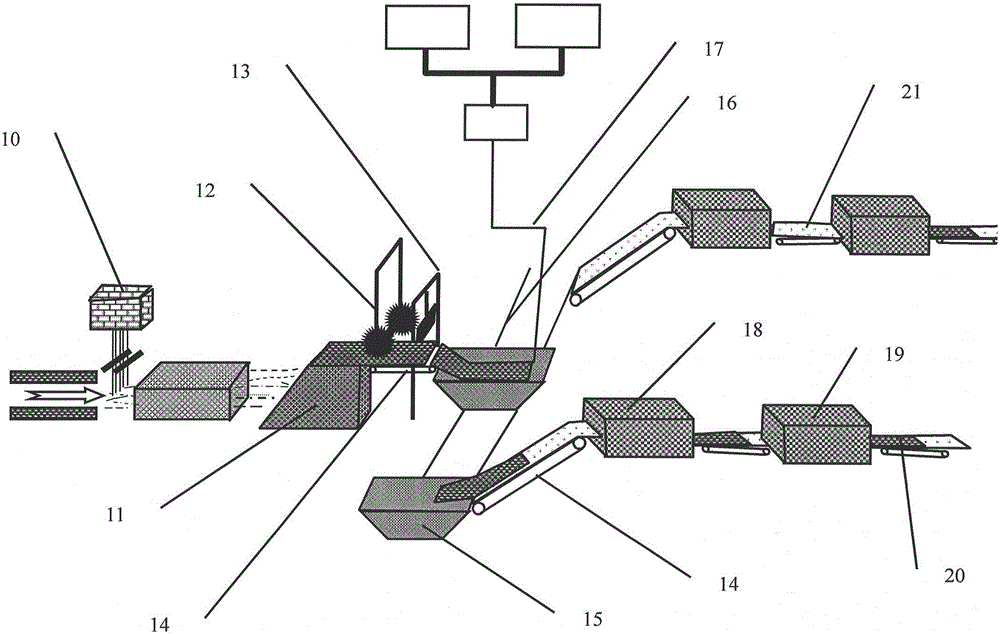

Image

Examples

Embodiment 1

[0023] A glass fiber mat reinforced silica airgel and a preparation method thereof, characterized in that the airgel raw material is composed of 40 parts by weight of glass fiber mat, 4 parts of silica airgel glue, 2 parts Modifier and 0.5 parts of water-soluble phenolic resin solution are composed of four parts; the density of the glass fiber mat is 5Kg / m 3 , the average fiber diameter is 0.5 μm, and the aspect ratio is 20; the volume composition of each component of the silica airgel glue is: 15 parts of silicon source precursor: 25 parts of absolute ethanol: 1 part of hydrolysis catalyst: 2 parts of gel catalyst: 30 parts of distilled water; The weight components of each component of the modifier are: 10 parts of flexible acrylic acid, 0.5 part of silicone oil, 0.05 part of silane, 0.5 part of ammonium sulfate, 20 parts of distilled water; The concentration of the phenolic resin solution is 15%, and the molecular weight of the phenolic resin is 2000; the preparation method ...

Embodiment 2

[0032] A glass fiber mat reinforced silica airgel and a preparation method thereof, is characterized in that the airgel raw material is composed of 70 parts by weight of glass fiber mat, 30 parts of silica airgel glue, 10 parts The modifier and 1 part of water-soluble phenolic resin solution are composed of four parts; the density of the glass fiber mat is 8Kg / m 3 , the average fiber diameter is 3 μm, and the aspect ratio is 300; the volume components of each component of the silica airgel glue are: 20 parts of silicon source precursor: 150 parts of absolute ethanol: 4 parts of hydrolysis catalyst: 6 Part gel catalyst: 60 parts of distilled water; The weight components of each component of the modifier are: 35 parts of flexible acrylic acid, 3 parts of silicone oil, 0.2 part of silane, 6 parts of ammonium sulfate, 45 parts of distilled water; The concentration of the resin solution is 20%, and the molecular weight of the phenolic resin is 3000; the preparation method of the ai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com