Wall-mounted cupboard

A wall-mounted, cabinet technology, applied in the field of cabinets, can solve the problems of life safety threats to users, easy to cause fires, and miss the best time for fire extinguishing, etc., to achieve good flame retardant effect, excellent char formation performance, and prevent dripping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

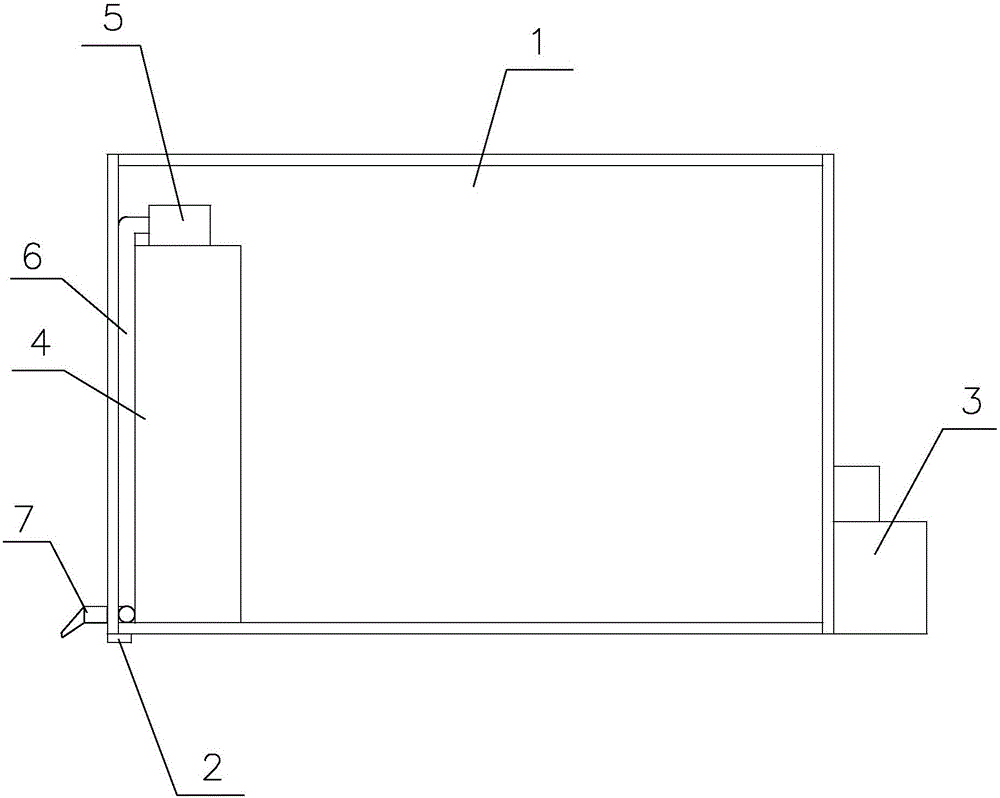

Image

Examples

Embodiment 1

[0032] 20 parts of polyacrylamide, 15 parts of melamine, 35 parts of ammonium polyphosphate, 8 parts of cyclodextrin, 42 parts of formaldehyde, 12 parts of vermiculite, 18 parts of perlite, 12 parts of ammonium dihydrogen phosphate, 6 parts of nano-zinc borate , 32 parts of water.

[0033] The specific steps include: (1) First, dissolve polyacrylamide, melamine, ammonium polyphosphate and cyclodextrin in formaldehyde according to the formula ratio, then stir and heat to 80°C for 22 minutes; then adjust the pH of the above reaction solution It is neutral; (2) Place vermiculite, perlite, ammonium dihydrogen phosphate and nano-zinc borate in water according to the formula ratio, stir evenly, then heat to 80℃, react for 20 minutes, and then adjust the pH of the reaction solution to 4-5 (3) Then the steps (1) and (2) are mixed and uniformly coated on the outer surface of the cabinet according to the weight ratio of 1:1, and painted 3-5 coats, each with an interval of 2.5h, and the coa...

Embodiment 2

[0035] The fireproof coating includes: 24 parts of polyacrylamide, 18 parts of melamine, 28 parts of ammonium polyphosphate, 8 parts of cyclodextrin, 43 parts by weight of formaldehyde, 18 parts of vermiculite, 28 parts of perlite, and 14 parts of ammonium dihydrogen phosphate Parts, 9 parts of nano zinc borate, 33 parts of water. The preparation steps are the same as in Example 1.

[0036] The fireproof performance of the fireproof board prepared by the present invention is shown in Table 1 below:

[0037] Table 1 Fire performance of Example 1-2

[0038]

[0039] By testing the fire resistance of the examples, it is also found that the oxygen index of the samples 1-2 of the present invention is between 40-50, and the formaldehyde emission is less than 1.0 mg / L. It can be seen from the above-mentioned embodiments that the product of the present invention has the advantages of good fire resistance and can be effectively applied to the cabinet fireproof board.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com