Construction method for filling dissolving cavity in outer side of deep foundation pit in karst area

A construction method and technology of deep foundation pits, applied in infrastructure engineering, construction, etc., can solve problems such as poor water sealing effect, achieve the effect of less investment, simple technical process, and small construction impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

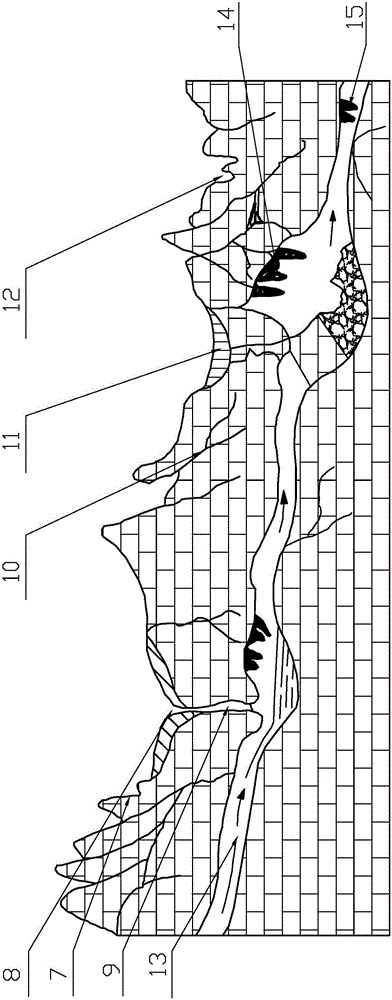

[0025] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, the method for filling the solution cavity outside the deep foundation pit in the karst area of this embodiment, the steps of the construction method are as follows:

[0026] Step 1: Preliminary judgment of the location of the dissolution cavity

[0027] Check the geological survey data, the drilling data of the retaining piles, and combine the water gushing conditions in the deep foundation pit to preliminarily determine the location range and depth range of the dissolution cavity (for example, the 5-7m range is displayed as the dissolution cavity in the drilling record table, check the geological survey There are also dissolved cavities in the range of 5-7m from the data, and the leaking position of the foundation pit happens to be within the depth of 5-7m, so it can be preliminarily determined that there is a dissolved cavity in this position.);

[0028] Step 2: Use DTH Dri...

specific Embodiment approach 2

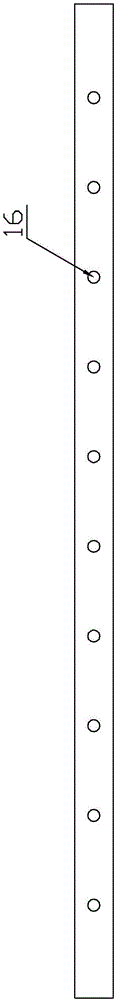

[0037] Specific implementation mode two: combination figure 2 To illustrate this embodiment, in step 3, the diameter of the lead hole drilled by the geological drill is 100mm. Designed so that it is easy to insert the grouting pipe. Other compositions and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0038] Specific implementation mode three: combination figure 2 To illustrate this embodiment, the floral tube in step 4 is made of iron pipe with a micro-pile material diameter of 42 mm and a wall thickness of 4 mm, and grout holes with a diameter of 10 mm are reserved every 500 mm on both sides of the tube axis. Such a design prevents the slurry hole from being blocked by the slurry in the dissolution cavity, and the slurry cannot be injected. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com