Bridge cushion pad embedded installation seat machining method

A processing method and technology of buffer pads, which are used in bridges, bridge construction, bridge parts, etc., can solve the problems of easy damage, poor surface corrosion resistance, low surface hardness of Dacromet coating, etc. It is not easy to deform and improves the overall corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

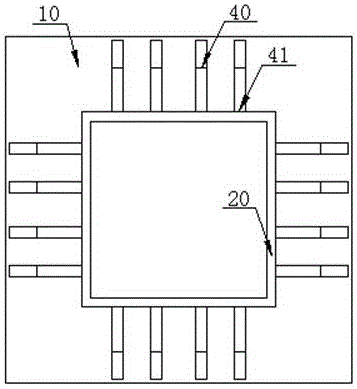

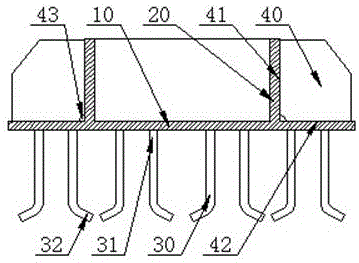

[0020] refer to Figure 1 to Figure 2 , Figure 1 to Figure 2 It is a structural schematic diagram of a pre-embedded mounting seat for a bridge cushion according to the present invention.

[0021] A method for processing a pre-embedded mounting seat of a bridge buffer pad provided in this embodiment includes the following steps:

[0022] Step 1, process the buffer pad limit frame 20 panel of square structure, assemble and weld four buffer pad limit frame 20 panels of square structure to form the buffer pad limit frame 20 of square tubular structure; process pre-embedded anti-floating steel bars 30, one end of the pre-embedded anti-floating steel bar 30 is bent to form a pre-buried lower end 32, and the other end of the pre-embedded anti-floating steel bar 30 is kept vertical as the welding upper end 31; the base plate 10 of the mounting base is processed, and the base plate 10 of the mounting base is processed into Square structure; processing the anti-deformation reinforced...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com