System and method for generating steam from blast furnace slag

A water vapor and blast furnace slag technology, which is applied to furnaces, furnace components, and energy efficiency improvement, can solve problems such as shortening the service life of heat exchangers, corrosion of heat exchangers, and failure to use blast furnace slag washing water to reduce consumption , The effect of facilitating the utilization of waste heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

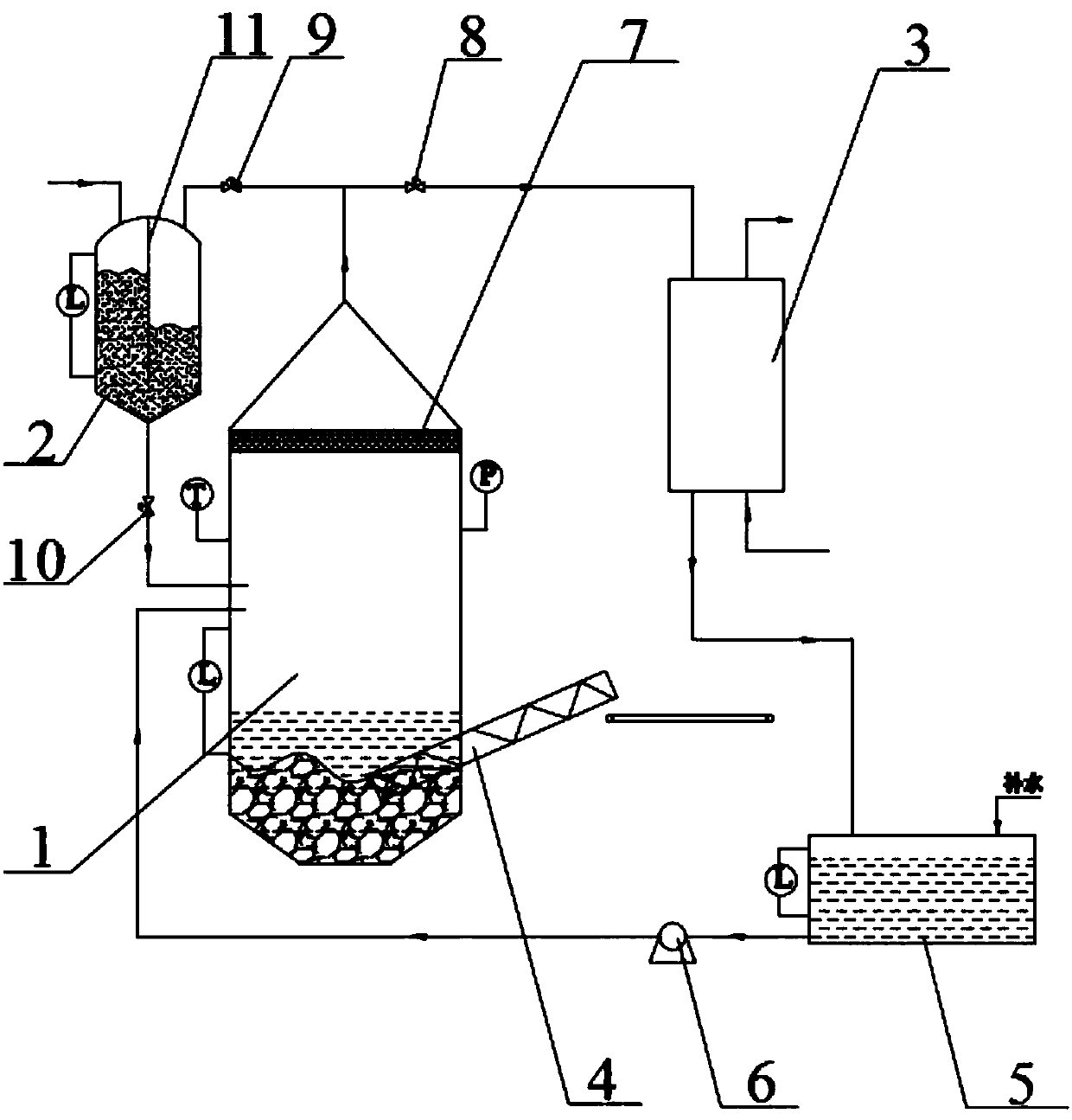

[0022] like figure 1 , The embodiment of the present invention provides a system for generating water vapor from blast furnace slag, including a buffer tank 2, a granulation tower 1 and a heat exchange mechanism. The entrance of the buffer tank 2 accepts the slag discharged from the blast furnace, and the outlet end communicates with the slag inlet of the granulation tower 1; wherein, the blast furnace slag is discharged into the buffer tank 2 through the slag ditch, and the bottom of the buffer tank 2 is drained The material pipeline is connected to the slag inlet of the granulation tower 1, and a discharge valve 10 is arranged on the discharge pipeline to control the flow rate of the slag entering the granulation tower 1. The granulation tower 1 is provided with a granulation water inlet, a water vapor outlet and a slag outlet, and the granulation water injected from the granulation water inlet quenches the slag discharged from the slag inlet to generate water Steam, the st...

Embodiment 2

[0028] The embodiment of the present invention relates to a method for generating water vapor from blast furnace slag, the method is as follows:

[0029] The buffer tank 2 receives the slag from the blast furnace, and continuously discharges the slag into the granulation tower 1 through the discharge valve 10 at the bottom of the buffer tank 2;

[0030] Spray granulation water into the granulation tower 1 to water-quench the slag to granulate the slag and generate water vapor. The granulated slag and slag are separated from water and discharged from the granulation tower 1. The water vapor is introduced into the heat exchange mechanism through the steam pipeline for further Waste heat utilization, the condensed water generated after the water vapor is heat-exchanged and condensed in the heat exchange mechanism is sent to the granulation tower 1 for recycling as granulation water;

[0031] Wherein, the granulation water level in the granulation tower 1, the pressure in the towe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com