A sealing device for a ring cooler

A sealing device and ring cooler technology, which is applied in the treatment of discharged materials, furnaces, lighting and heating equipment, etc., can solve the problems that dynamic and static seals cannot solve the air leakage of the ring cooler, and achieve the benefits of waste heat utilization and help. Cooling effect, easy assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

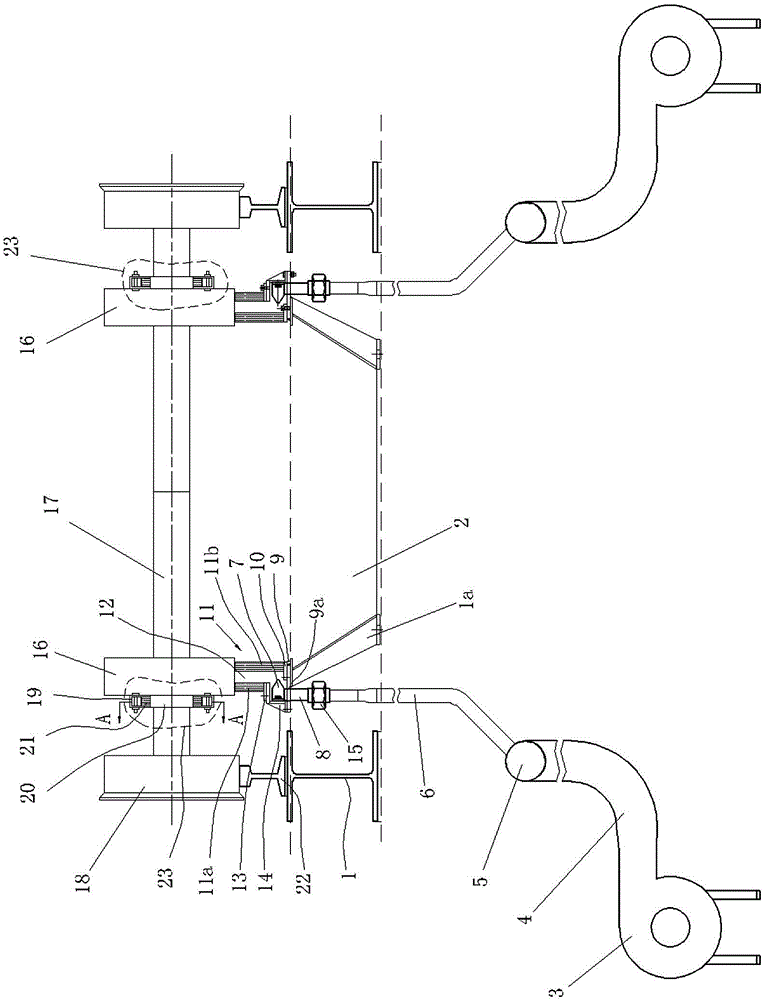

[0025] Such as figure 1 As shown, a sealing device for an annular cooler provided by the present invention includes a set of fixing frames 1, and the fixing frames 1 form a ring structure, and two rows of rails 22 are symmetrically connected to the inside and outside of the fixing frame 1, respectively. A group of wheels 18 are symmetrically arranged on the two rows of rails 22, and the two mutually symmetrical wheels 18 are connected through the axle 17, and the carriage 16 is connected on the axle 17, and the bellows fixing seat 1a is also provided on the fixed frame 1. , cooperate and connect the bellows 2 between the bellows fixing seats 1a, characterized in that:

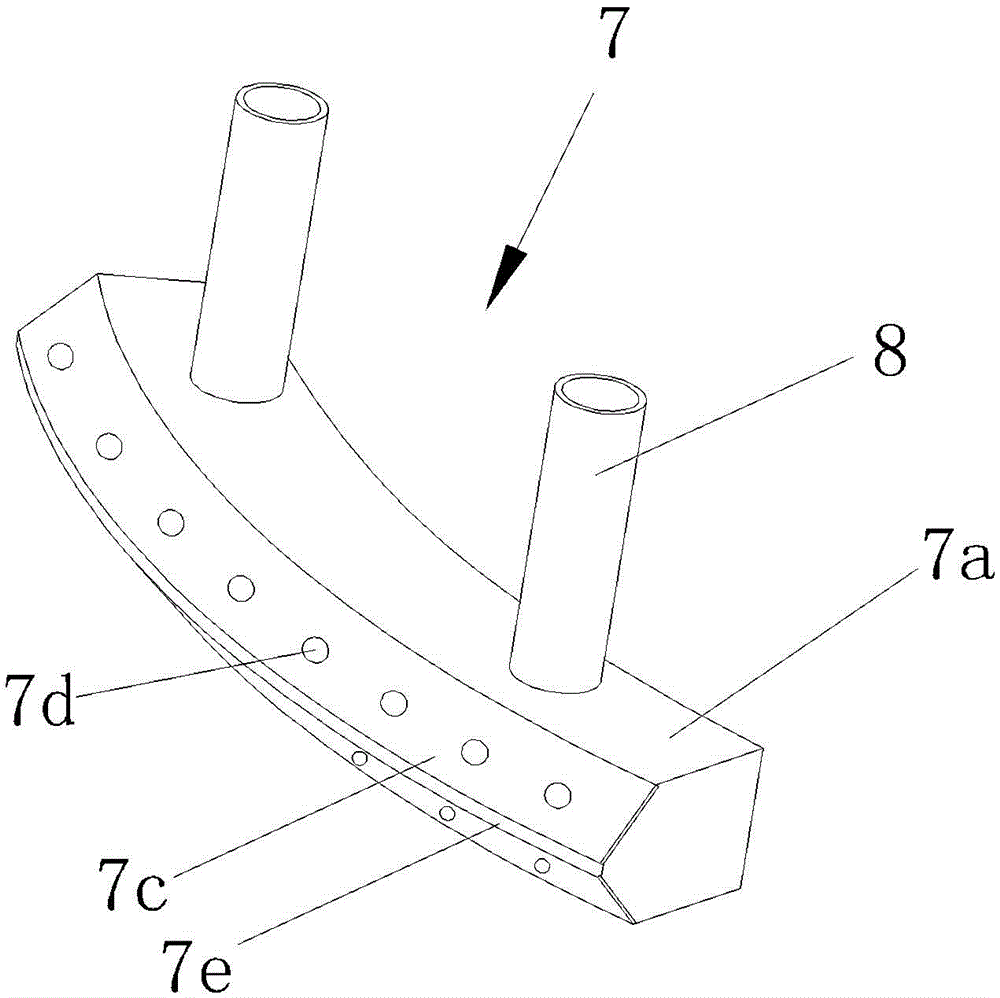

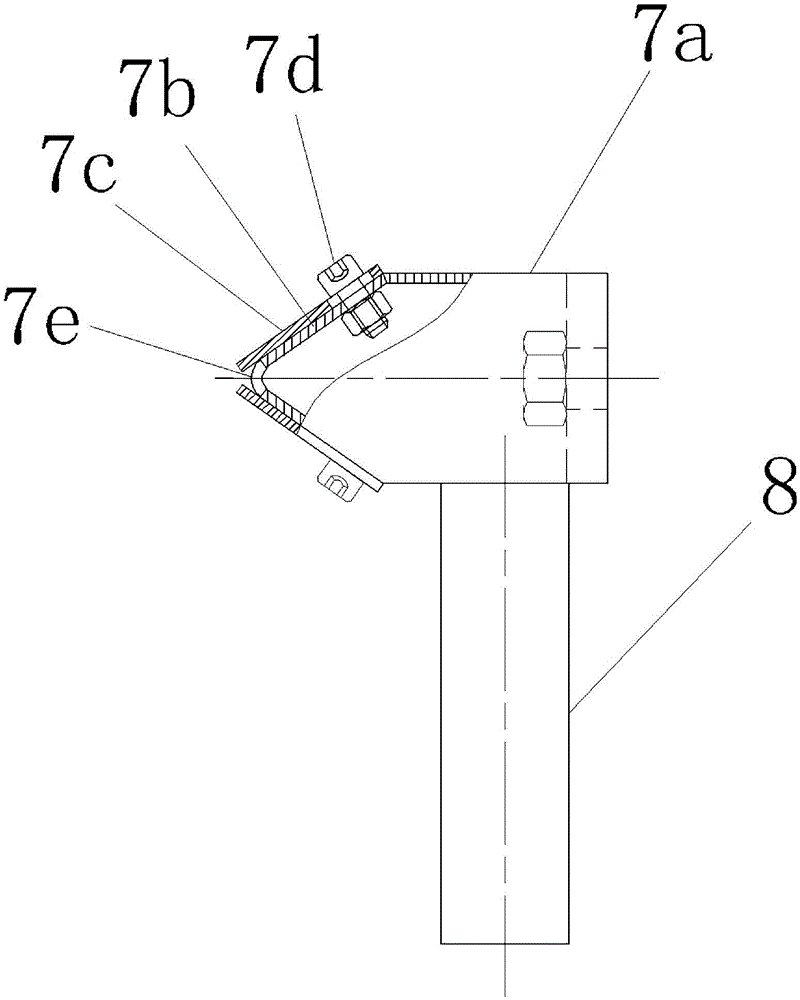

[0026] a. Two rows of steel brushes 11 are connected on the outside and inside of the bellows 2 on the bellows fixing seat 1a, and a steel brush bottom plate 21a is welded on the outside and inside of the bellows 2 on the bellows fixing seat 1a. Each of the fixing plates 9 is provided with a group of through h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com