Method for preparing industrial calcium chloride from thiourea waste residues

A technology of industrial calcium chloride, thiourea waste residue, applied in the direction of calcium/strontium/barium chloride, calcium/strontium/barium halide, etc., to achieve the effect of great economic value and environmental protection value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

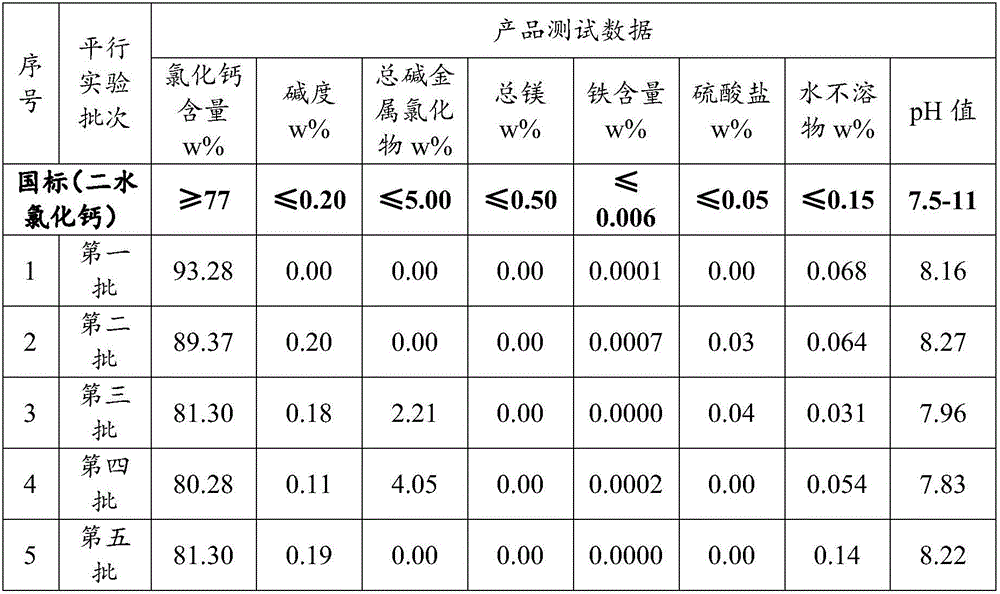

Examples

Embodiment 1

[0041] A kind of method that is raw material production industrial grade calcium chloride with thiourea waste residue and industrial hydrochloric acid, its concrete steps are:

[0042] (1) Stir and wash the thiourea waste residue at 80° C. for 30 min with clear water having the same quality as the thiourea residue, and filter with suction to obtain waste residue with low thiourea content (0.1% thiourea content).

[0043] (2) Prepare a 25% concentration hydrochloric acid solution with carbon-containing waste slag primary washing water (clear water for the first batch of reaction) and industrial hydrochloric acid (hydrochloric acid concentration 35%).

[0044](3) Take by weighing 200g 25% concentration hydrochloric acid solution in the 500ml four-neck flask, stir, slowly add thiourea waste residue (thiourea content 0.1%) in the hydrochloric acid solution, the addition time is controlled at 1-1.5 hours, and the reaction is exothermic, The water bath temperature control is less th...

Embodiment 2

[0051] A kind of method that is raw material production industrial grade calcium chloride with thiourea waste residue and industrial hydrochloric acid, its concrete steps are:

[0052] (1) Use clean water with the same quality as the thiourea residue to stir and wash the thiourea residue at 70° C. for 30 minutes, and filter with suction to obtain waste residue with low thiourea content (0.2% thiourea content).

[0053] (2) Prepare a 30% concentration hydrochloric acid solution with carbon-containing waste slag primary washing water (clear water for the first batch of reaction) and industrial hydrochloric acid (hydrochloric acid concentration 35%).

[0054] (3) Take by weighing 200g 30% concentration hydrochloric acid solution in the 500ml four-neck flask, stir, slowly add thiourea waste residue (thiourea content 0.2%) in the hydrochloric acid solution, the time of adding is controlled at 1-1.5 hour, and reaction exotherm, The temperature of the water bath is less than 40°C.

...

Embodiment 3

[0061] A kind of method that is raw material production industrial grade calcium chloride with thiourea waste residue and industrial hydrochloric acid, its concrete steps are:

[0062] (1) Stir and wash the thiourea waste residue at 65° C. for 30 min with clear water of the same quality as the thiourea waste residue, and filter with suction to obtain waste residue with low thiourea content (0.3% thiourea content).

[0063] (2) Get industrial hydrochloric acid (hydrochloric acid concentration 35%).

[0064] (3) Take by weighing 200g 35% concentration hydrochloric acid solution in the 500ml four-neck flask, stir, slowly add thiourea waste residue (thiourea content 0.25%) in the hydrochloric acid solution, the addition time is controlled at 1-1.5 hours, and the water bath temperature control is less than 65°C.

[0065] (4) When the pH value of the reaction solution was 4.5, stop adding thiourea waste residue, continue to stir and react for 30 minutes, and then suction filter to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com