Device for machining irregular uneven surface of wood plate

A technology of concave-convex surface and processing device, applied in metal processing equipment, manufacturing tools, grinding machines, etc., can solve the problems of high labor intensity of operators, high operating technical requirements, uneven surface unevenness, low cost, low labor intensity, Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

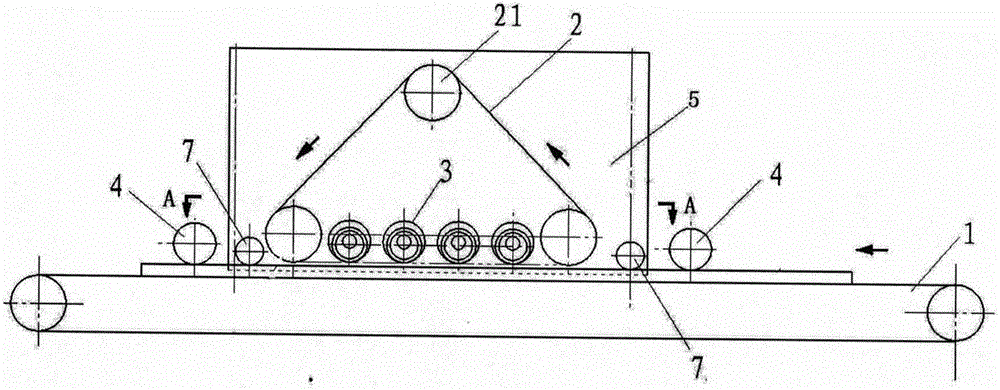

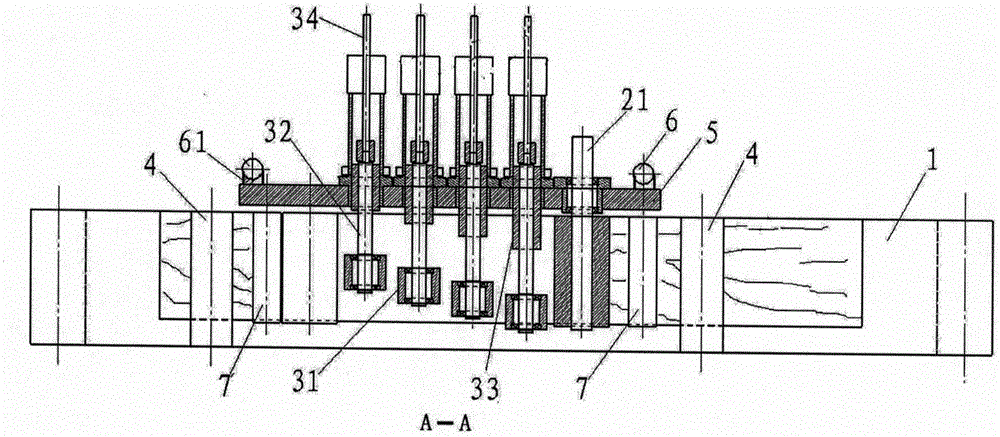

[0012] Such as figure 1 , 2 As shown, a device for processing irregular concave-convex surfaces of wooden boards includes a conveyor belt 1, an abrasive belt 2, and a pressure roller 3. The conveyor belt 1 is arranged horizontally. The conveyor belt 1 can be an ordinary conveyor belt, that is, the drive wheel is driven by a motor to rotate. Then drive the crawler belt set on the transmission wheel to rotate to realize the transmission and spreading of the wooden board. Preferably, the crawler belt of the conveyor belt with less gap and greater frictional resistance is selected to improve the drag force of the wooden board; 2 is set above the plate for grinding the plate; the pressure roller 3 is set above the abrasive belt 2, which can move up and down in the direction perpendicular to the plate, and whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com