An improved bearing grease injection device

A grease injection device, an improved technology, applied in mechanical equipment, engine components, engine lubrication, etc., can solve problems such as low efficiency, grease leakage, uneven grease injection, etc., to reduce labor intensity, ensure cleanliness, well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

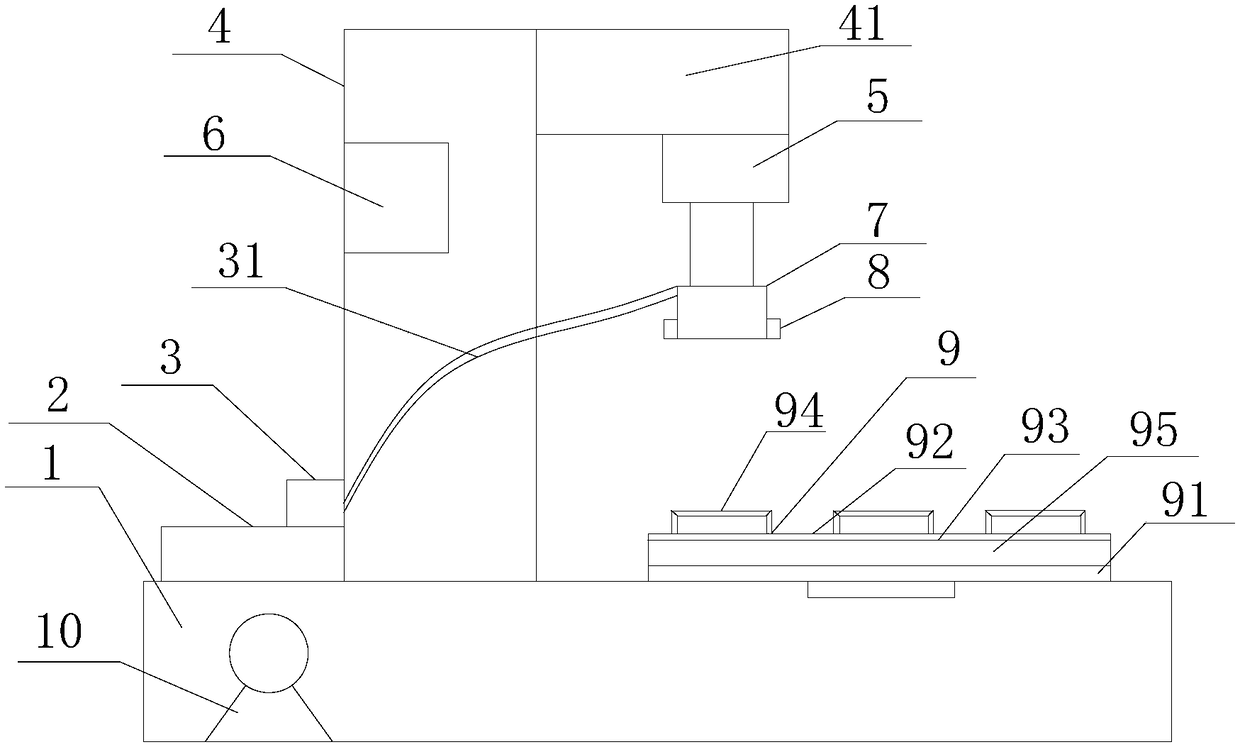

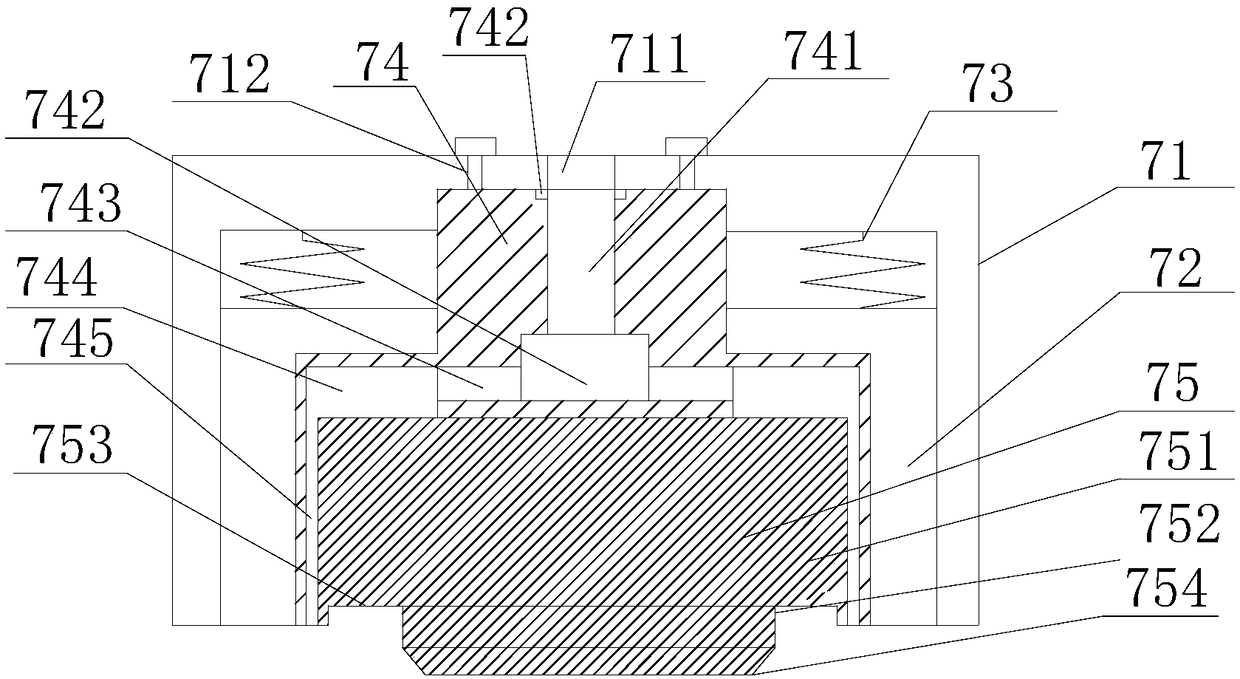

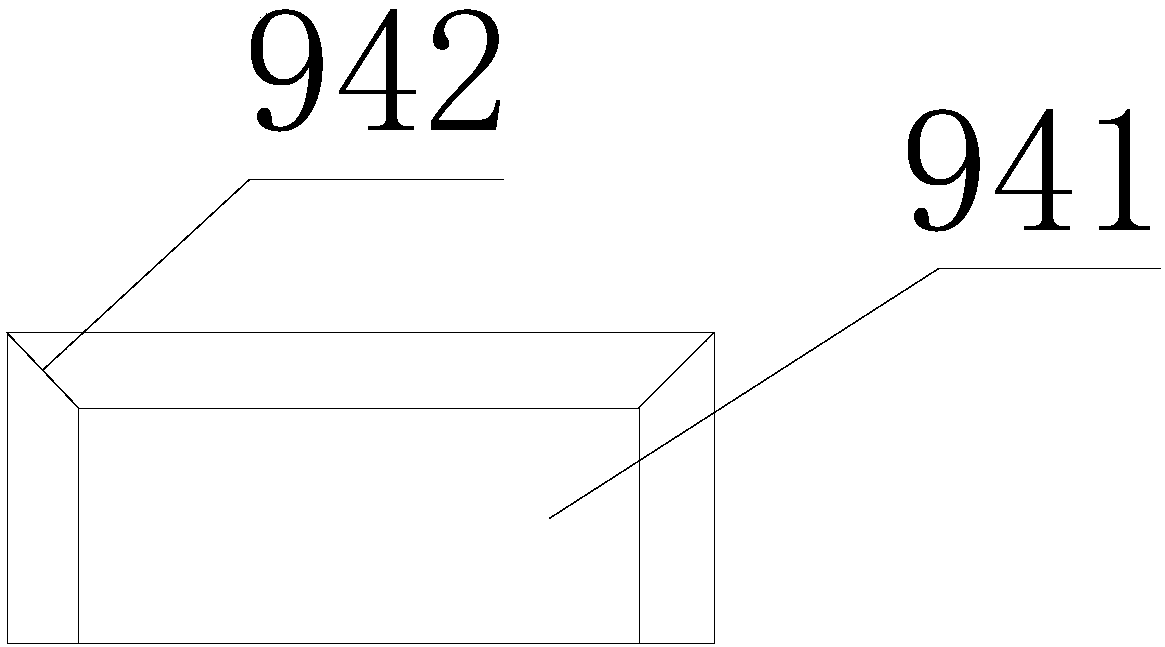

[0016] refer to figure 1 , figure 2 and image 3 , an improved bearing grease injection device of the present invention, including a workbench 1, an oil drum 2, a quantitative pump 3, a first mounting bracket 4, an electric hydraulic cylinder 5, a control system 6, a grease injector 7, a proximity sensor 8, a positioning Device 9, and servo motor 10, described workbench 1 is provided with first mounting bracket 4, and described first mounting bracket 4 is provided with cantilever shaft 41, and electric hydraulic cylinder 5 is installed below described cantilever shaft 41, so A grease injector 7 is installed below the telescopic shaft of the electric hydraulic cylinder 5, and a grease injector installation sleeve 71 is arranged inside the grease injector 7. The longitudinal section shape of the grease injector installation sleeve 71 is U-shaped. A grease injection device 74 is provided inside the grease injector installation sleeve 71, and a grease injection chassis 75 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com